A method for growing large-sized sapphire single crystal over 80kg

An 80kg, large-size technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of large size sapphire single crystal easy to stick, many internal defects, easy to produce polycrystalline, etc., to avoid polycrystalline And the crystal is easy to fall off the pot, reduce the heat dissipation capacity, and reduce the effect of the internal stress of the crystal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

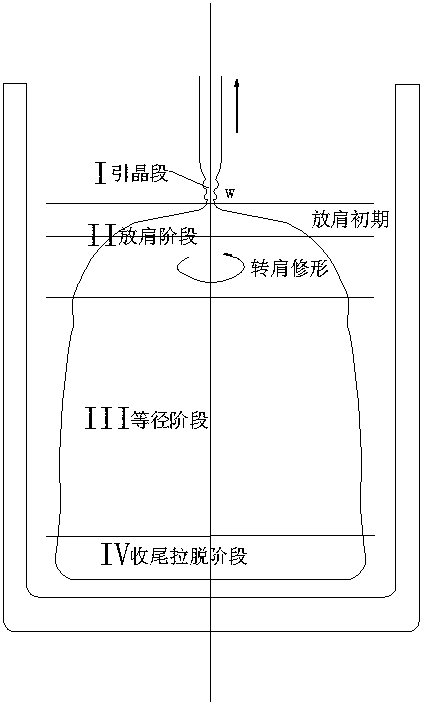

[0023] figure 1 It is a schematic diagram of the process flow of the crystal growth stage. According to the characteristics of the process control stage, the crystal is artificially divided into four parts, which correspond to the control stages of the growth process: the seeding stage I, the shouldering stage II (subdivided into the initial stage of shouldering and shoulder modification) , Isometric stage III and finishing pull-off stage IV, and finally cooling annealing.

[0024] Take the growth of 80kg sapphire single crystal as an example: put 80kg of alumina raw material into the crucible, and seed the crystal according to the method described in the authorized patent 20111007243.0. In the initial stage of shouldering, set the voltage and pulling parameters to -4mv / h and 0.1mm / h respectively to ensure that the single crystal grows slowly at a rate of 0.05kg / h. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com