Slab continuous casting chamfer crystallizer narrow-face copper plate capable of effectively controlling longitudinal cracks of corners

A technology of chamfering mold and slab continuous casting, which is used in the field of narrow-faced copper plate and slab continuous casting chamfering mold narrow-faced copper plate, can solve the problem of poor practicability, without considering the heat transfer and heat transfer of mold chamfered surface and billet shell. The effect of growth, the lack of clear key part size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

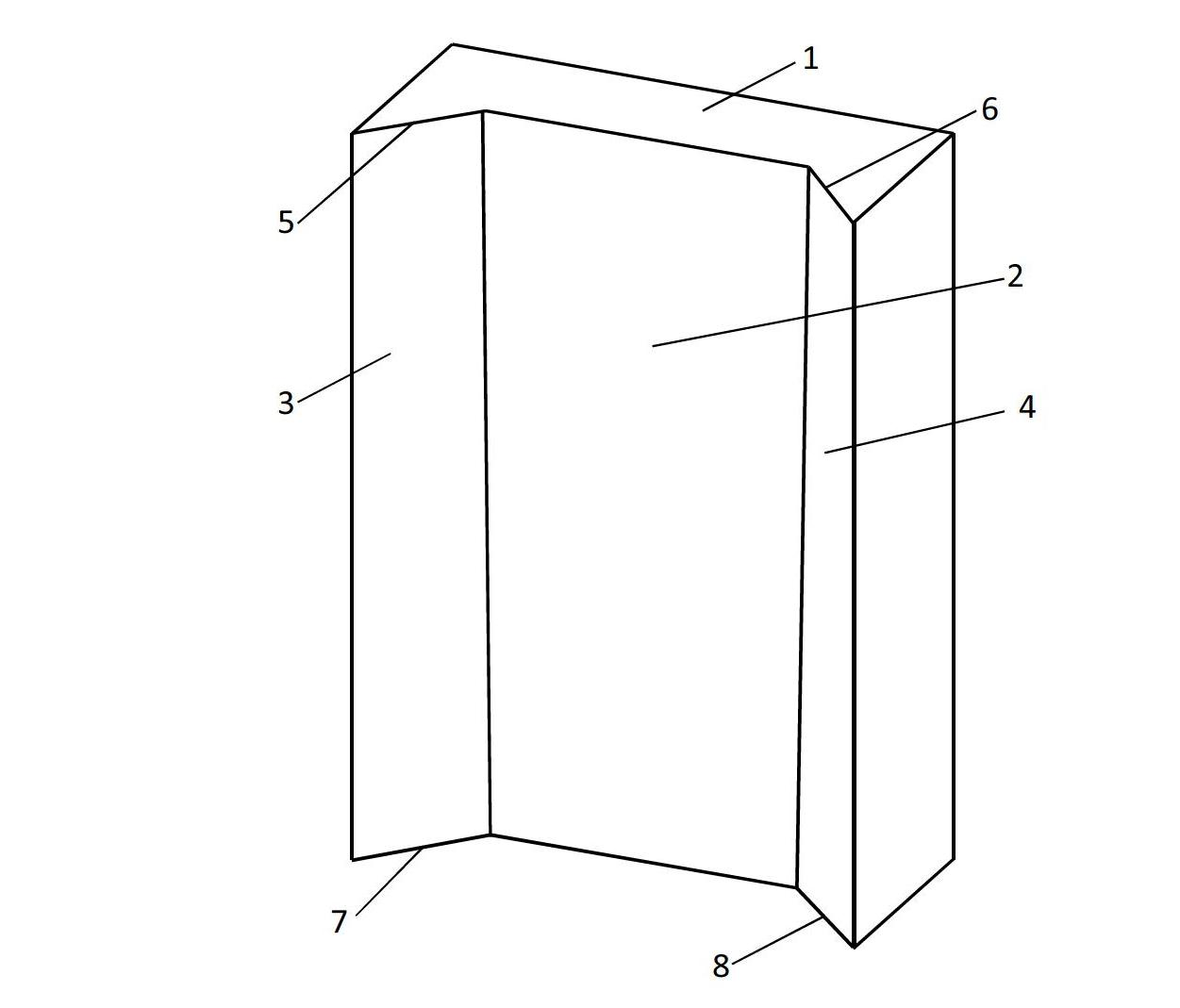

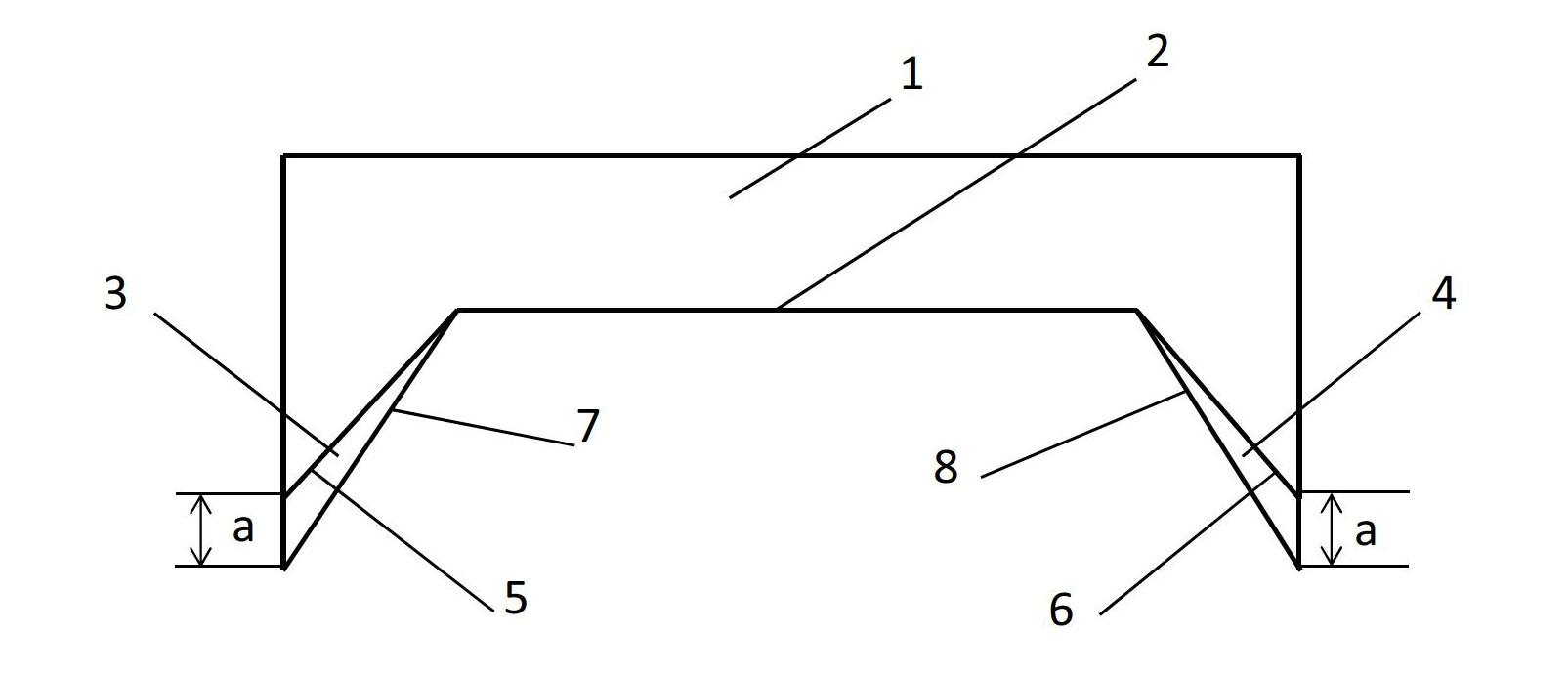

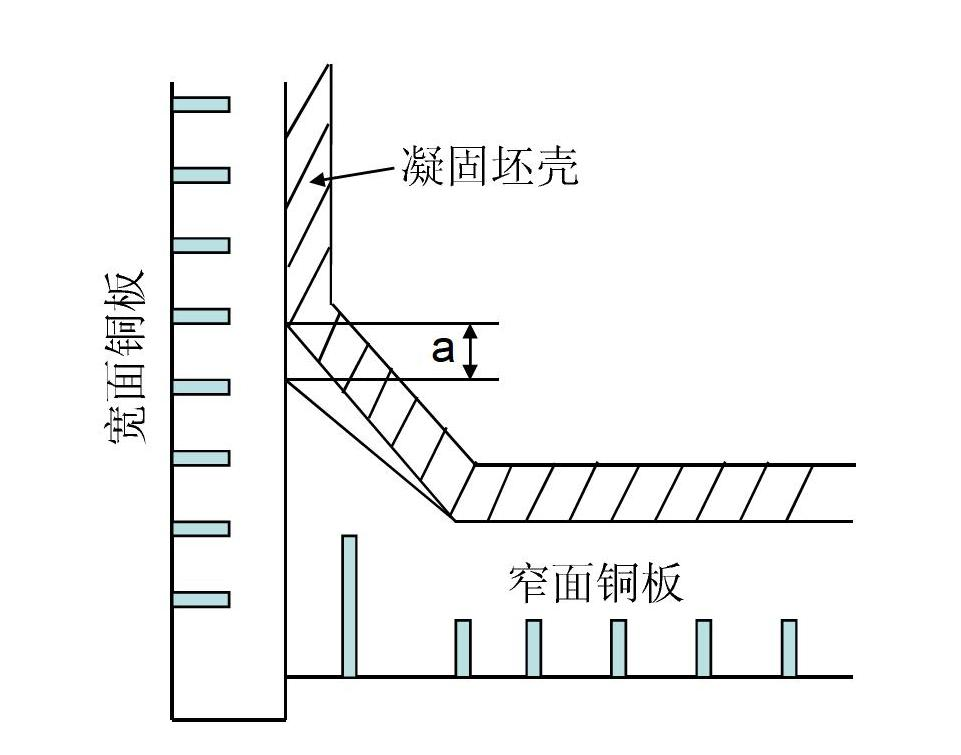

[0026] A steel plant adopted the chamfering crystallizer copper plate of the present invention when casting 220mm×1800mm continuous casting slabs on a continuous casting machine. The included angle between faces 2 is 135°, the taper compensation a designed for the shrinkage of the wide-face billet shell in the mold on the chamfer face is 0.50mm, the taper coefficient of the narrow-face copper plate is 1.10%, and the casting speed is 1.2m / min, the cast continuous casting slab has no corner longitudinal crack defects, and the rolled 20-40mm steel plate surface has no black lines and fold defects.

Embodiment 2

[0028] A steel plant adopted the chamfering crystallizer copper plate of the present invention when casting 250mm×2400mm continuous casting slabs on a continuous casting machine. The included angle between faces 2 is 135°, the taper compensation a designed for the contraction of the wide-face billet shell in the mold on the chamfer face is 1.20mm, the taper coefficient of the narrow-face copper plate is 1.15%, and the casting speed is 1.0m / min, the cast continuous casting slab has no corner longitudinal crack defects, and the rolled 20-60mm steel plate surface has no black lines and folding defects.

Embodiment 3

[0030] A steel factory adopted the chamfering crystallizer copper plate of the present invention when casting 300mm×2000mm continuous casting slabs on a continuous casting machine. The included angle between faces 2 is 135°, the taper compensation amount a designed for the contraction of the wide-face billet shell in the mold on the chamfer face is 1.0mm, the taper coefficient of the narrow-face copper plate is 1.25%, and the casting speed is 0.85m / min, the cast continuous casting slab has no corner longitudinal crack defects, and the rolled 40-80mm steel plate surface has no black lines and folding defects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com