Method and device for preventing steel leakage of continuous casting and continuous pouring blank

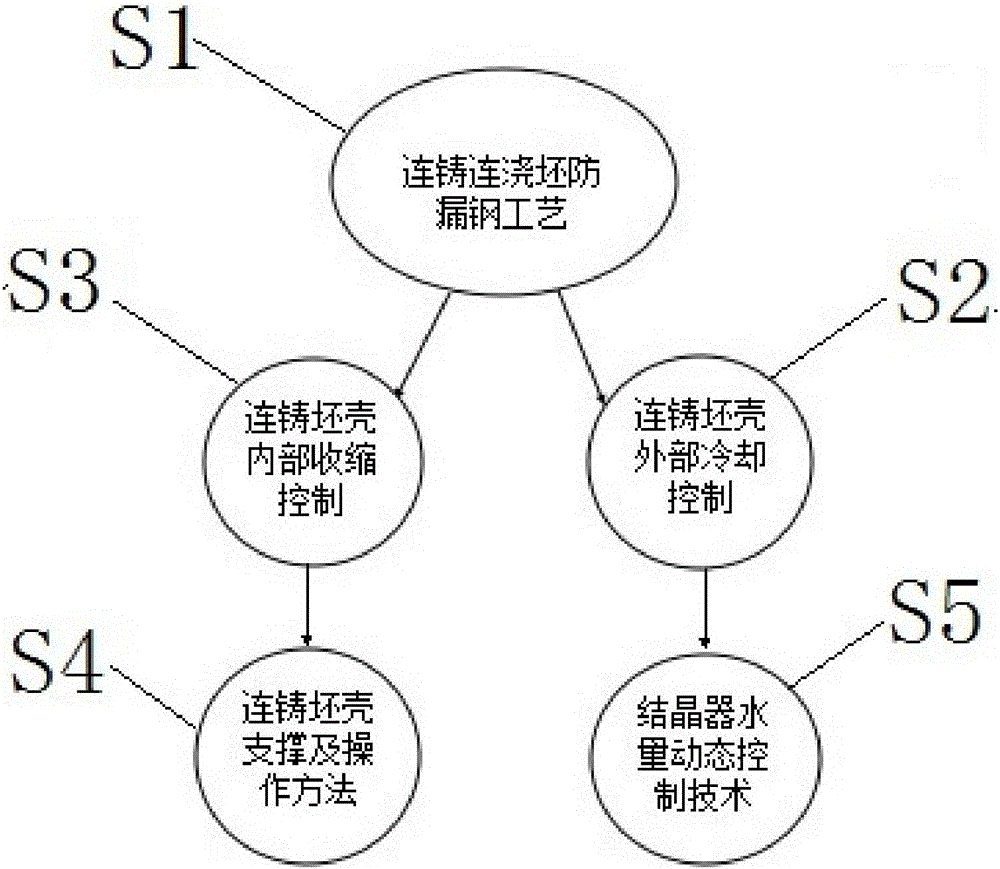

A continuous casting billet and continuous pouring technology is applied in the field of continuous casting technology to achieve the effect of preventing steel breakout accidents and producing stable and smooth production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

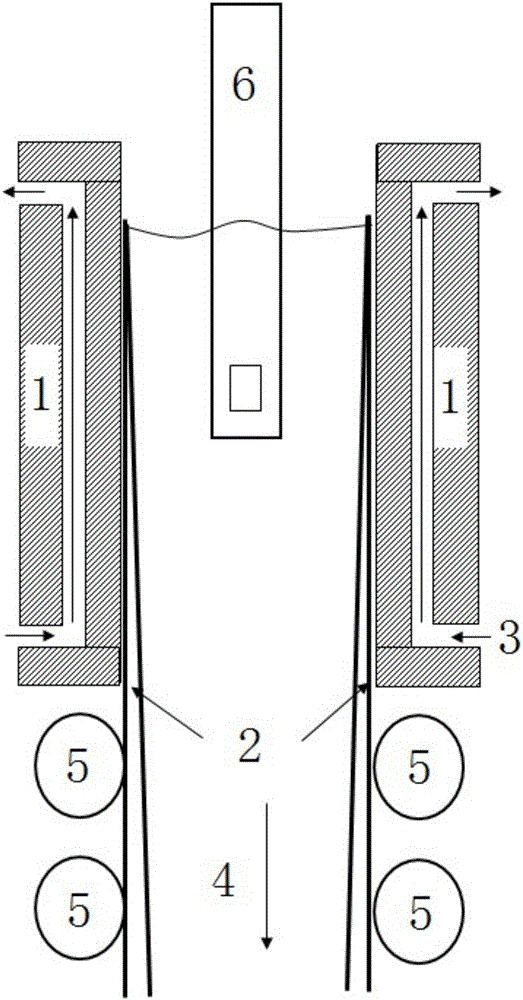

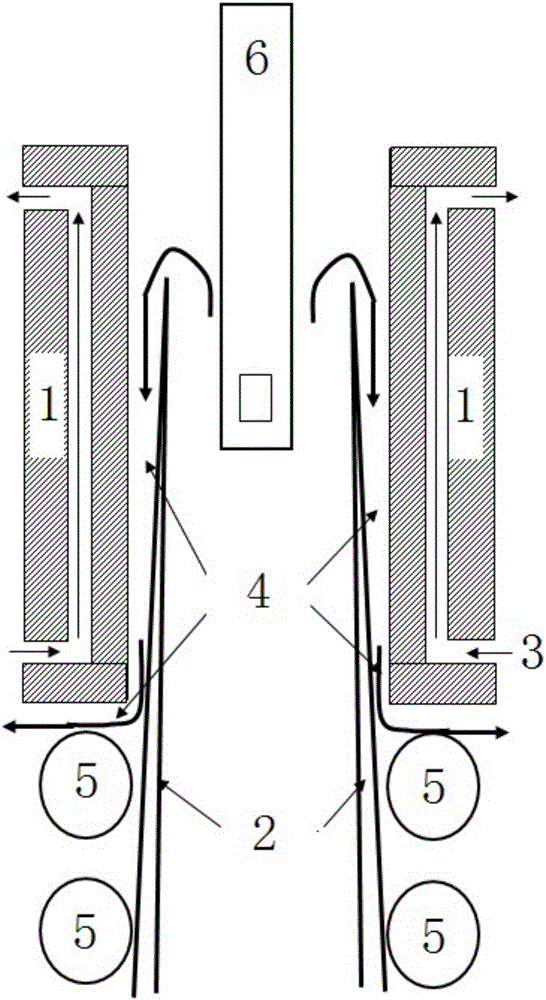

[0094] For a certain steel type, the water volume of the crystallizer during pouring is 2600L / min for the wide side and 340L / min for the narrow side. When preparing for the continuous pouring operation of tundish replacement, when the pouring speed drops to 0.8m / min, press the "Crystal Water Volume Change" button on the operation panel.

[0095] Have 2-3 support inserts ready.

[0096] When the speed continues to decrease to 0.5m / min, confirm that the crystallizer cooling water adjustment valve is closed, and the water volume begins to drop to the target value, wide side: 2210L / min, narrow side: 290L / min.

[0097] Immediately after the crystallizer is cut off, insert the supporting piece evenly along the width direction in the crystallizer (more than 50mm away from the nozzle position).

[0098] After continuing to pull the liquid level of the crystallizer to the position of the outlet of the submerged nozzle, stop casting.

[0099] The tundish replacement operation is carri...

Embodiment 2

[0103] For a certain steel type, the pouring section is 1900mm, and the mold water volume during pouring is 3600L / min for the wide side and 430L / min for the narrow side. When preparing for the continuous pouring operation of submerged nozzle replacement, the crystallizer needs to be cut off. When the pouring speed drops to 0.8m / min, the operator presses the "Module Water Volume Change" button on the operation panel.

[0104] Have 4 support inserts ready.

[0105] When the speed continues to decrease to 0.5m / min, confirm that the crystallizer cooling water adjustment valve is closed, and the water volume begins to drop to the target value, wide side: 2400L / min, narrow side: 320L / min.

[0106] Immediately after the crystallizer is cut off, insert 4 supports evenly along the width direction in the crystallizer (more than 50mm away from the nozzle position).

[0107] After continuing to pull the liquid level of the crystallizer to the position of the outlet of the submerged nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com