Warning device for preventing middle package from bleeding-out

A technology of an alarm device and a tundish, which is applied in the metallurgical field, can solve problems such as failure to fundamentally solve the leakage accident, and achieve the effect of preventing the occurrence of the leakage accident, the structure is simple, and the alarm is accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

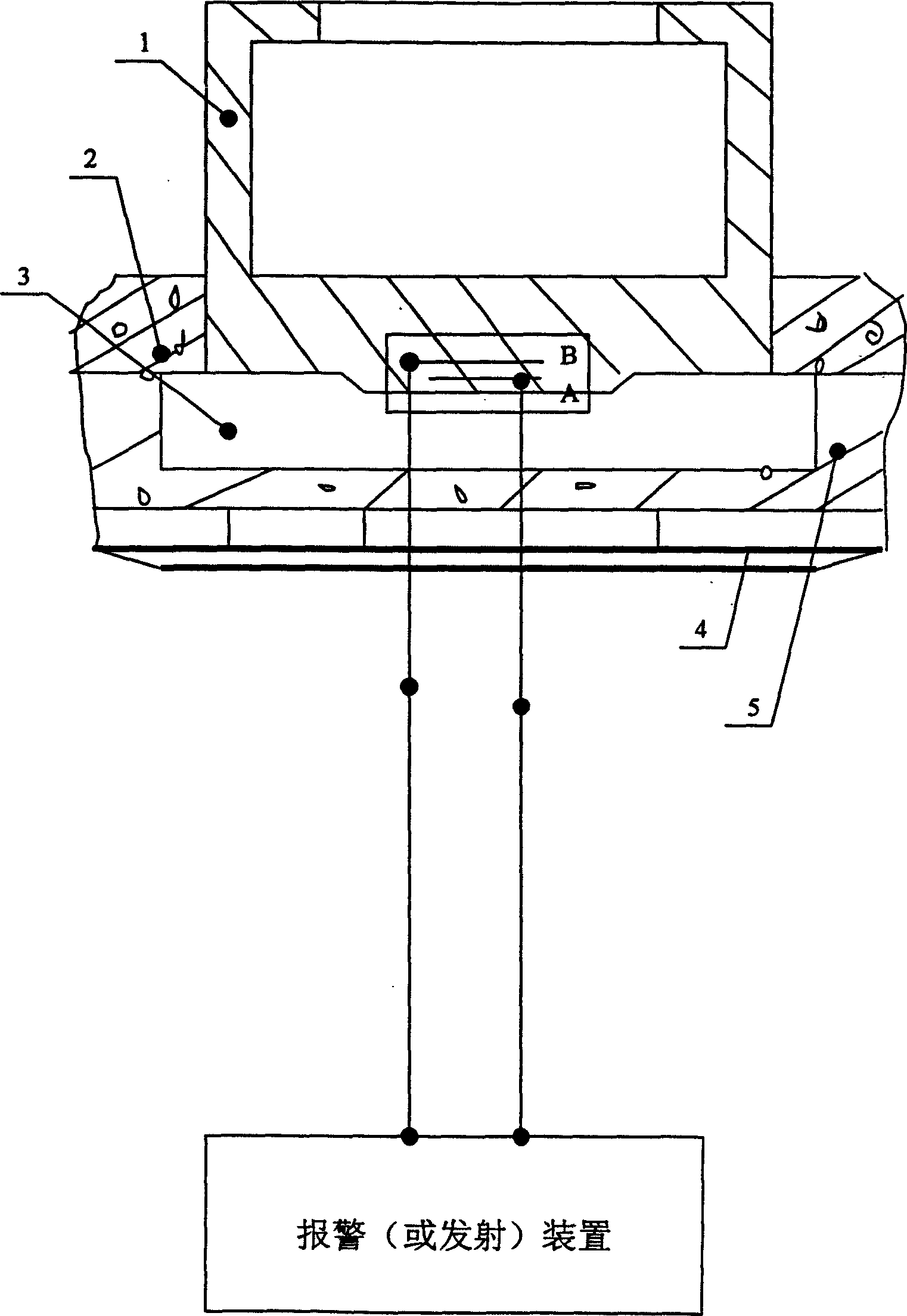

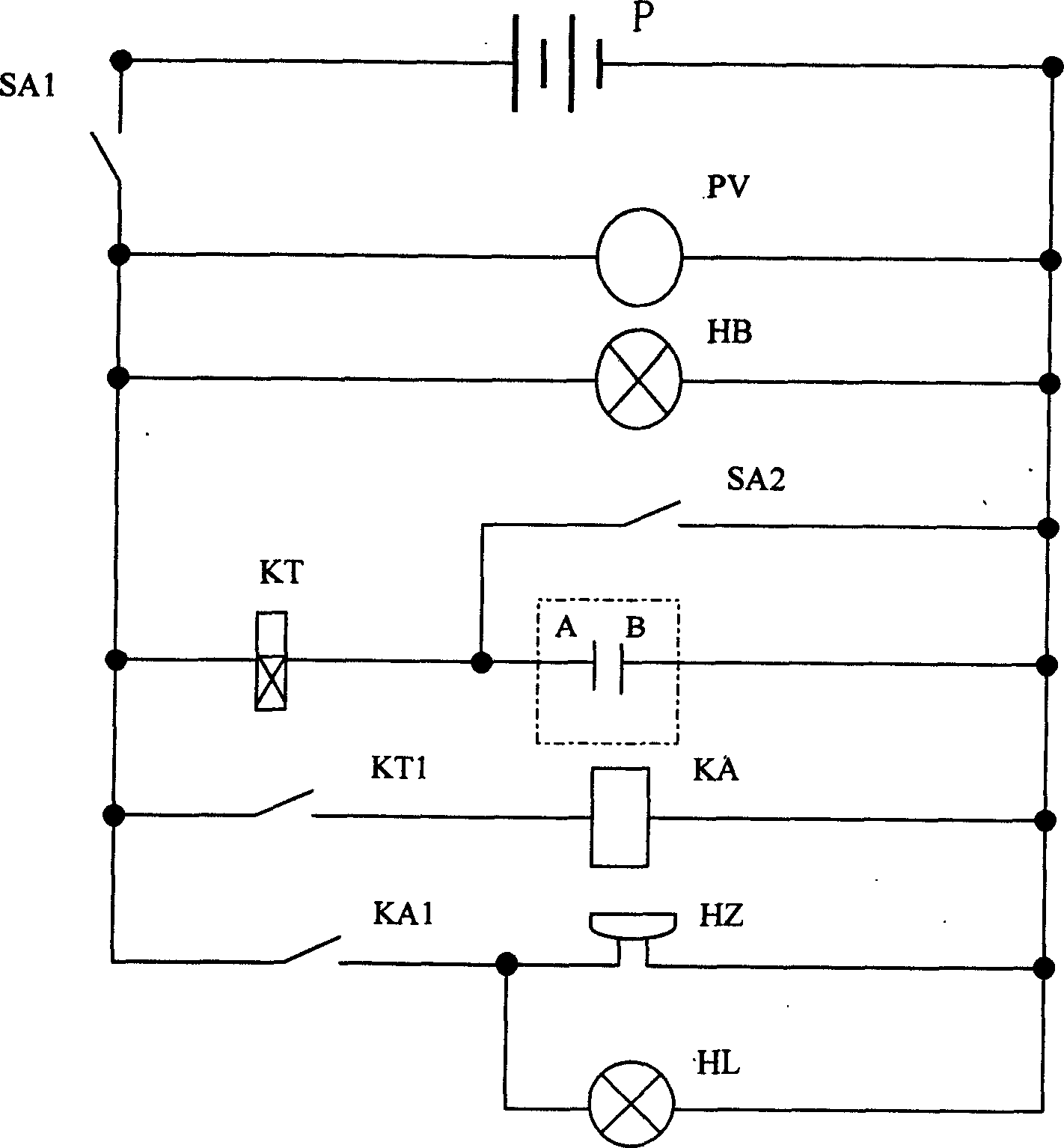

[0011] Overall structure of the present invention is as figure 1 As shown, when impact bricks or turbulence controllers are installed in the impact area of the tundish, the molten steel conduction element is installed in the impact bricks or the bottom wall of the turbulence controller and connected to the external alarm through wires. Such as figure 2 Shown: the alarm consists of power supply P, manual shape switches SA1 and SA2, voltmeter PV, indicator light HB and red indicator light HL, molten steel conduction element AB, time relay KT, delay contact KT1, relay KA, contacts Switch KA1, alarm HZ and related wires. Among them, the power supply P, manual switch SA1 and indicator light HB are connected in series to form the basic circuit of the whole device, the voltmeter PV is connected in parallel with the indicator light HB, the molten steel conduction element AB is connected in parallel with the manual switch SA2 and then connected with the time relay KT Connected in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com