Tombarthite core-spun yarn for continuous casting

A cored wire and rare earth technology, applied in the field of iron and steel smelting, can solve the problems of affecting the quality of finished steel billets, increasing billet cracks, and performance degradation, so as to improve the utilization rate of rare earths, reduce unit costs, and improve steel quality.

Inactive Publication Date: 2004-03-17

曾宪刚

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional method of adding rare earths is mainly to directly add rare earth wires into the crystallizer through a wire feeder, so that the rare earths can directly react with molten steel to purify steel and refine grains. However, the crystallizer protection added on the surface of the crystallizer The slag layer, due to the reaction with the added rare earth wire, degrades its performance. In the process of continuous casting and pouring steel, it may cause molten steel slag, affect the quality of the finished billet, and increase the probability of cracks in the billet. Serious Will directly lead to caster breakout accidents

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

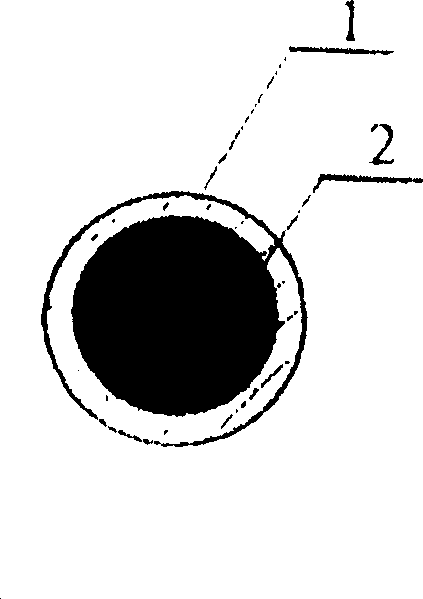

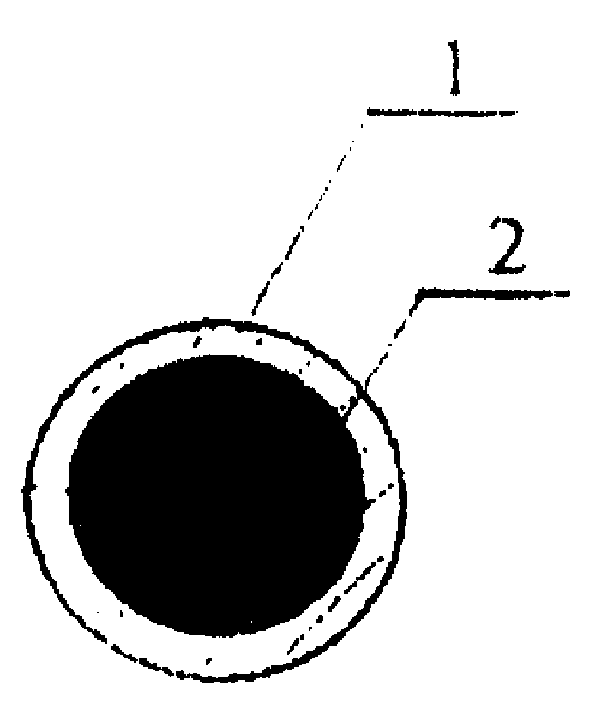

[0009] As shown in the accompanying drawings, the cored wire includes: a sheath 1 and a core 2. The filamentous or powdery core is wrapped in the sheath, the sheath 1 is a steel sheath, and the core 2 is made of rare earth wire or rare earth powder. The diameter of the core wire is 2mm or 6mm, or 12mm.

[0010] The core-spun rare earth wire or rare earth powder is mixed rare earth mainly composed of cerium and lanthanum.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The coated RE wire for continuous casting includes outer casing and wire core coated inside the casing, the outer casing is of steel and the wire core of rare earth material. It may be used in continuous casting to prevent crystallizer protecting dregs from performance degradation, ensure the quality and output of steel product, lower steel production cost and reduce bleedout accidents.

Description

technical field [0001] The invention relates to the technical field of iron and steel smelting, in particular to a rare earth cored wire for continuous casting. Background technique [0002] With the improvement of metallurgical continuous casting ratio, in some special steel types, especially high-quality steel and high value-added steel such as heat-resistant steel and weather-resistant steel, the method of adding rare earth from the continuous casting crystallizer with a wire feeder is adopted. Compared with the steel without adding rare earth, the total amount of oxygen, sulfur and inclusions of rare earth is lower, and the grain is refined by 1-2 grades, but the mechanism of action is not clear. The traditional method of adding rare earths is mainly to directly add rare earth wires into the crystallizer through a wire feeder, so that the rare earths can directly react with molten steel to purify steel and refine grains. However, the crystallizer pro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22D11/108B22D27/20C21C7/04

Inventor 曾宪刚余志祥张寿荣陈念铀骆忠汉李江邹阳扬运超

Owner 曾宪刚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com