Three-dimensional laser point cloud automatic fusion algorithm for converter in steel furnace

A fusion algorithm and 3D laser technology, applied in image data processing, instruments, etc., can solve problems such as short service life, marker detection, influence of data fusion accuracy, connection difficulties, etc., to ensure safe production and prevent steel breakout accidents in converters , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

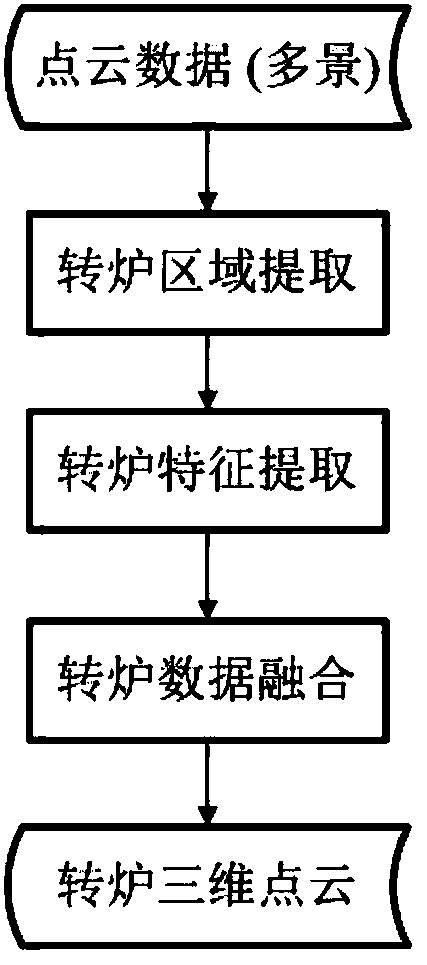

[0026] Such as figure 1 As shown, the processing flow of this algorithm includes three main parts, converter area data extraction, converter feature extraction, and converter point cloud data fusion.

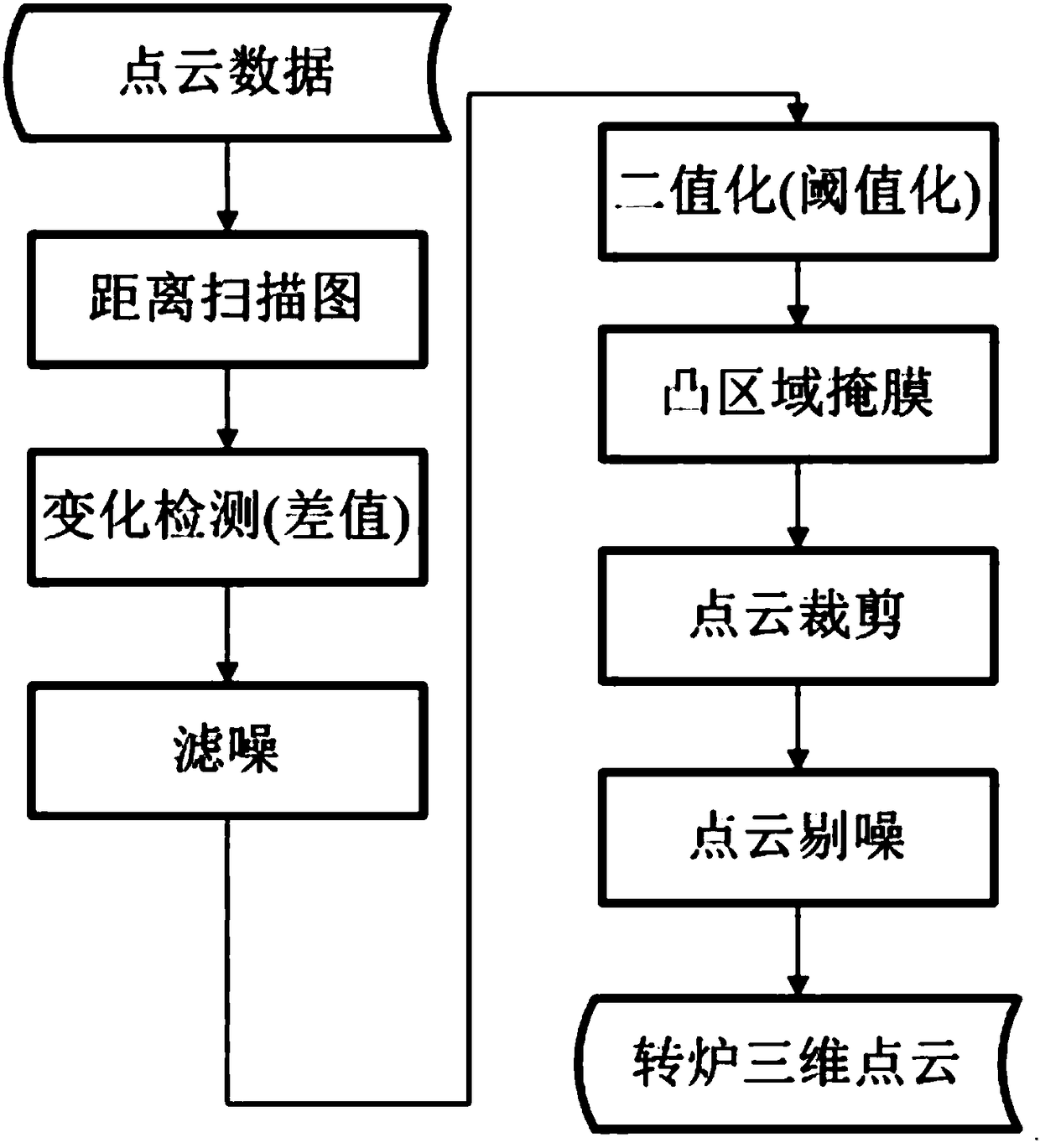

[0027] For multiple observation data at the same location (converter rotates at different angles), two different methods are used to extract the converter area: (a) point cloud direct phase difference method, (b) scanned image phase difference method.

[0028] The point cloud direct difference rule directly takes the reference data (a certain data selected from the observed multiple sets of data) as the benchmark, and then subtracts other observed data from the reference data; Set a certain tolerance limit (3d distance threshold), the tolerance limit here is related to the nominal accuracy of the instrument and the distance between the measuring points, the range here is roughly 0.5 ~ 2cm (the nominal accuracy of the instrument is 3mm@10m, the distance measurement about 10m); f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com