Casting method capable of reducing longitudinal cracks in surfaces of wide and thick plate continuous casting billets

A technology for wide and thick plates and continuous casting billets is applied in the field of casting to reduce longitudinal cracks on the surface of continuous casting billets of wide and thick plates, so as to optimize the production process, solve the longitudinal cracks in the casting, and reduce the superheat of the casting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

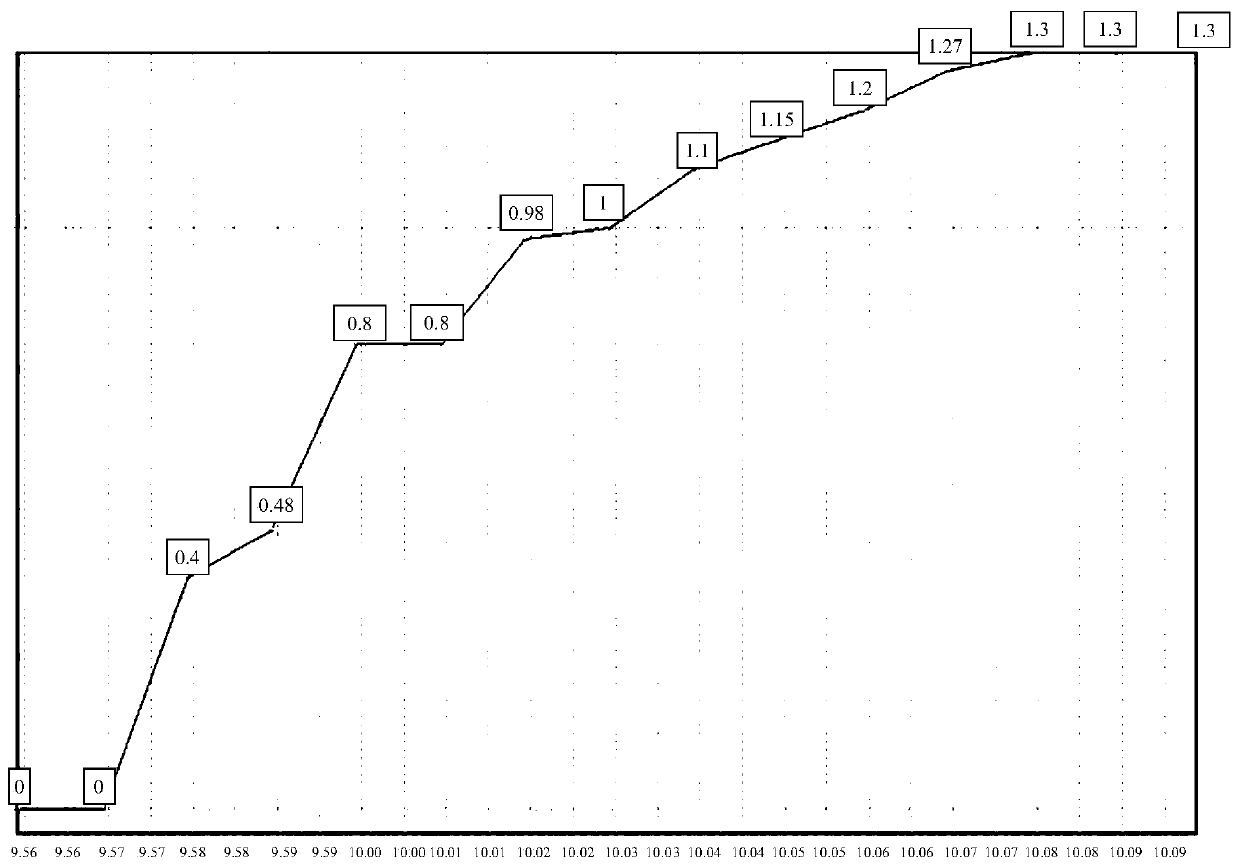

[0027] A pouring method for reducing longitudinal cracks on the surface of thick slab continuous casting slabs, the pouring method is:

[0028] 1. Before starting pouring, determine the temperature of the steel in the refining process according to the condition of the ladle and the temperature drop in the process, so as to ensure that the superheat of the tundish at the beginning of pouring is not too high, specifically 10-20°C.

[0029] 2. Confirm that the "big arm high position light" and "roaster high position light" on the operation box of the tundish car are on; loosen the stopper locking device;

[0030] 3. Immediately after pressing the "Pouring Position" button of the operation box, the tundish will automatically rise to the highest position, and the tundish car will run to the "Pouring Position"; during the walking process of the tundish car, remove the submerged nozzle insulation felt and check the side hole of the nozzle and inner cavity;

[0031] 4. Close the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com