Method for splicing highfill roadbed by adopting pile-sheet retaining wall

A high filling and roadbed technology, applied in sheet pile walls, roads, roads, etc., can solve problems such as affecting driving safety, difficulty in maintaining access, and large differences in stiffness, saving construction period, saving construction period, and piling speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

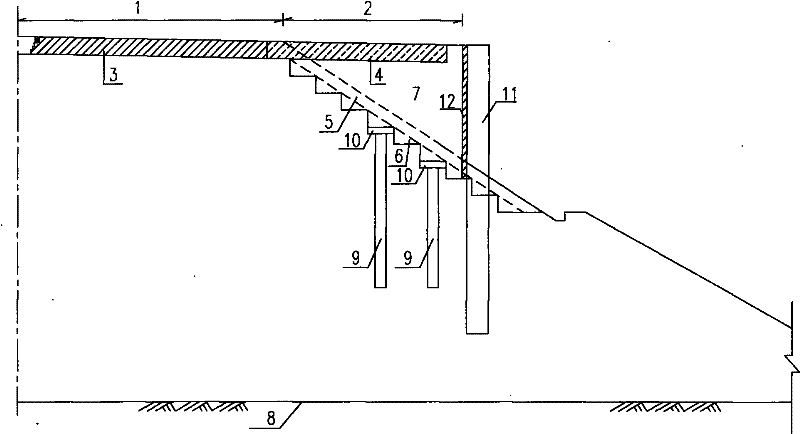

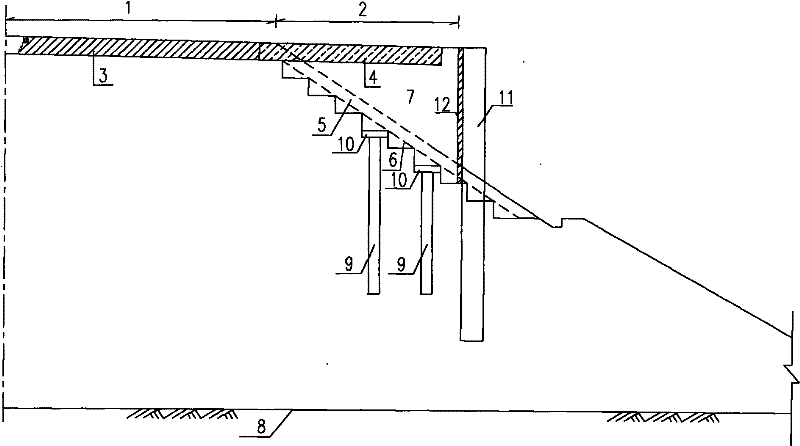

[0021] figure 1 Shown is the method of splicing new and old roadbeds by setting pile-plate retaining walls on the upper slope to close the slope. It is a 6-8m platform on the upper part of the high fill to carry out the construction of excavated cast-in-place concrete piles and retaining plates. That is to say, carry out the construction of side slope cutting 5 and excavation step 6 near the height of 6-8m meters of the side slope of the old roadbed 1 to ensure that there is a wider construction platform at the lower part, and then carry out the construction of digging hole-in-place piles 11 longitudinally, and the cast-in-place piles are embedded in the soil. In order to play an anchoring role, the exposed cast-in-place pile plays a supporting role. At the same time as the construction of the excavated cast-in-place piles 11, firstly carry out the construction of slope cutting 5 and excavation steps 6 on the slope surface where the foundation reinforcement is carried out at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com