Protective slag for continuous casting medium thick plate of low alloy high strength steel

A low-alloy, high-strength, continuous casting mold slag technology, applied in the field of continuous casting mold slag, can solve the problems of reduced productivity, inability to organize billet hot and red delivery, and large frictional resistance, so as to achieve low scrap rate and avoid Micro-cracks, the effect of reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

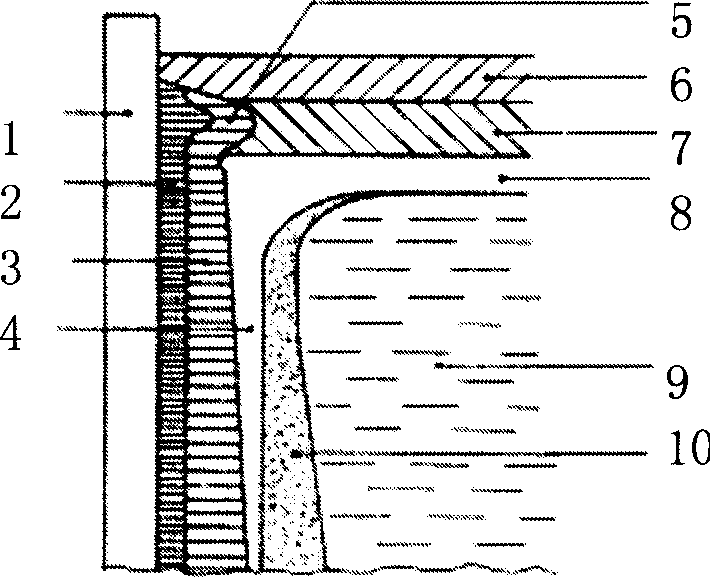

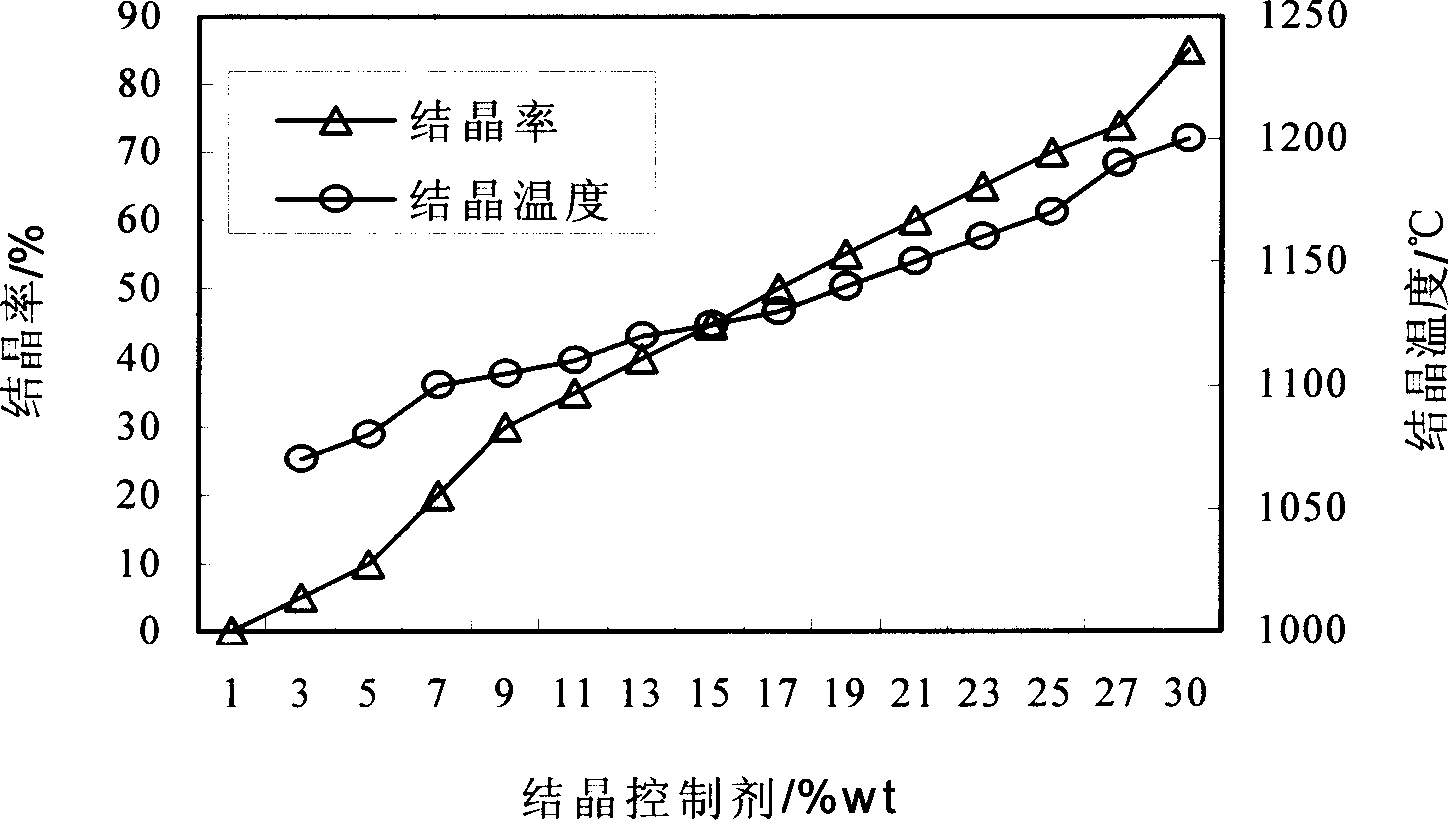

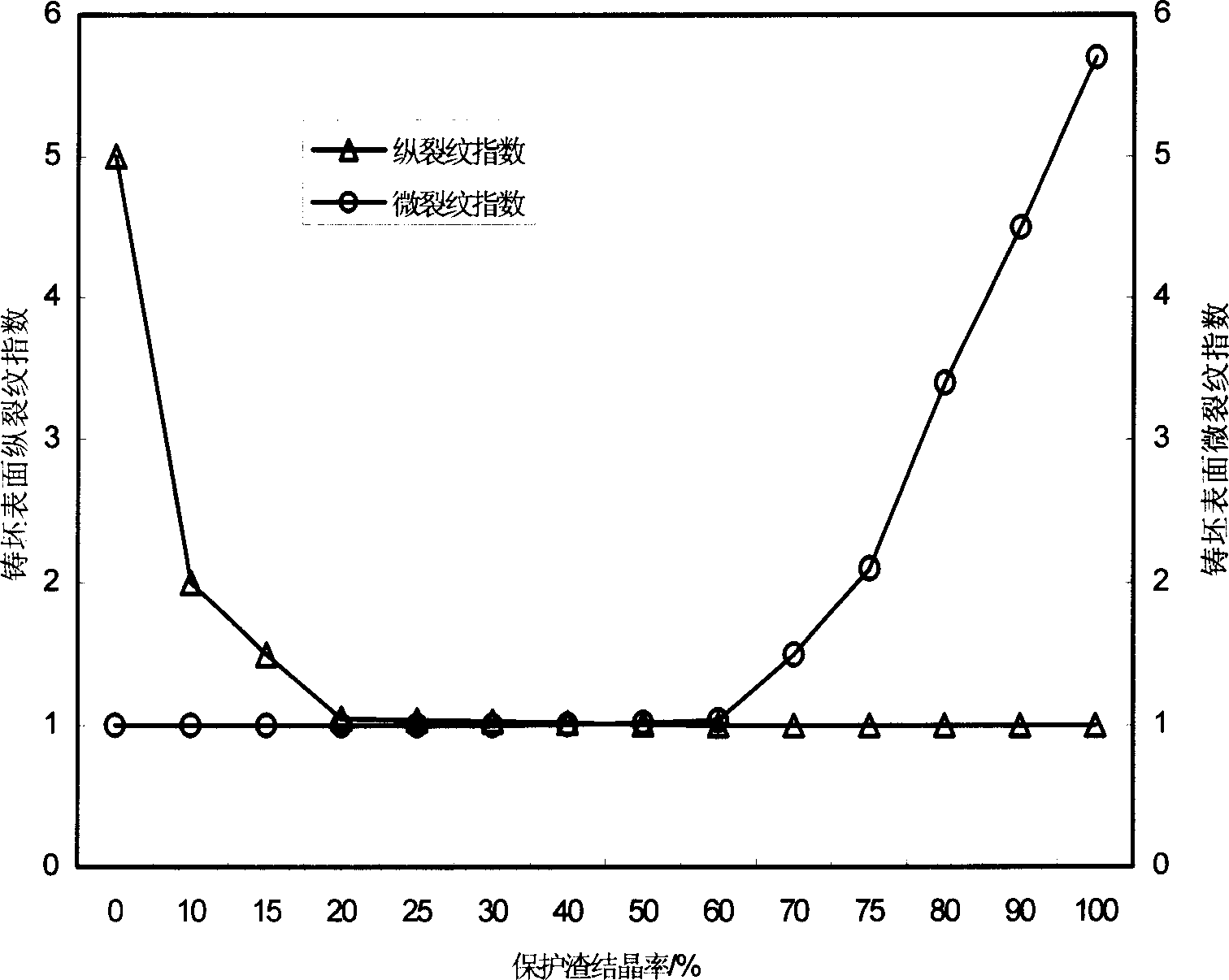

[0020] The invention relates to a mold flux for medium and heavy plate continuous casting of low-alloy high-strength steel. The components (weight%) of the mold flux are: 0.5-2.0 carbon black, 4-10 graphite, 4-12 Na 2 O, F from 1 to 7 - , Al of 2 to 7 2 o 3 , 1 to 3 Fe 2 o 3 , 7~20 crystallization control agent, 0~2 Li 2 O, the rest are CaO and SiO 2 ; Among them, CaO / SiO 2 0.90 to 1.05.

[0021] In the mold flux of the present invention, CaO and SiO 2 As the base material, the basicity of mold flux is controlled by their ratio. The purpose is to control the mold slag film in the critical state from glass state to crystal, so that most of the slag film is still in glass state, which is beneficial to the lubrication of the billet, and a small part of the crystalline state is conducive to controlling the uniformity of heat transfer sex. If the alkalinity is too low, the slag film is all glass, and the heat transfer capacity is too strong, which will cause serious long...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com