Transverse pre-stress I-shaped box girder structure

A technology of transverse prestressing and I-beams, applied to bridges, bridge parts, bridge materials, etc., can solve problems such as shortening the service life of bridges, increasing maintenance costs and difficulties, affecting normal use and operation of bridges, and achieving improved resistance. Torsional stability, reduced maintenance and repair times, improved overall stability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

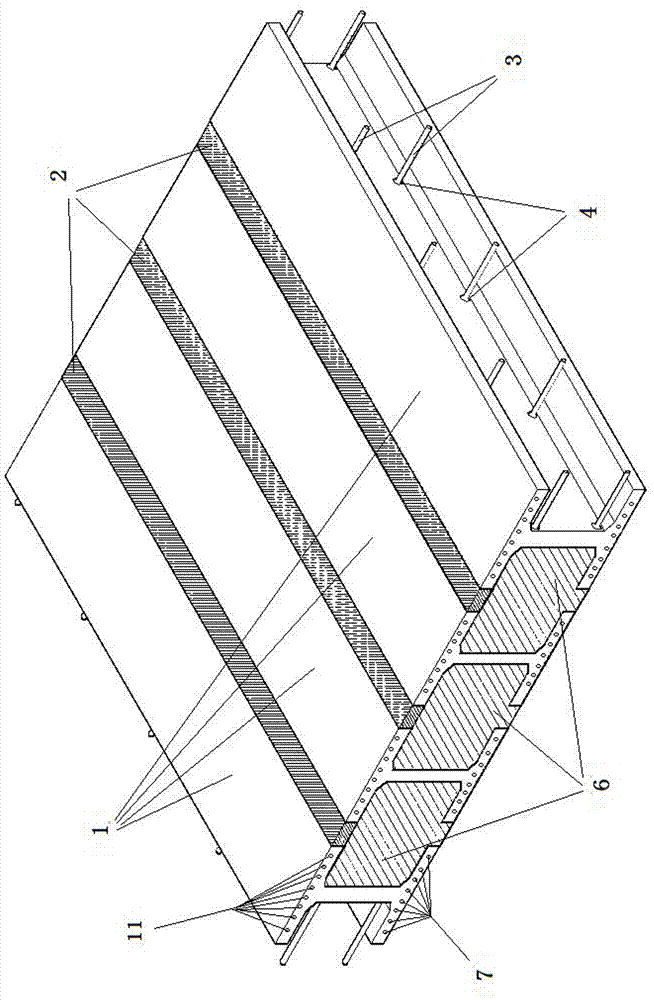

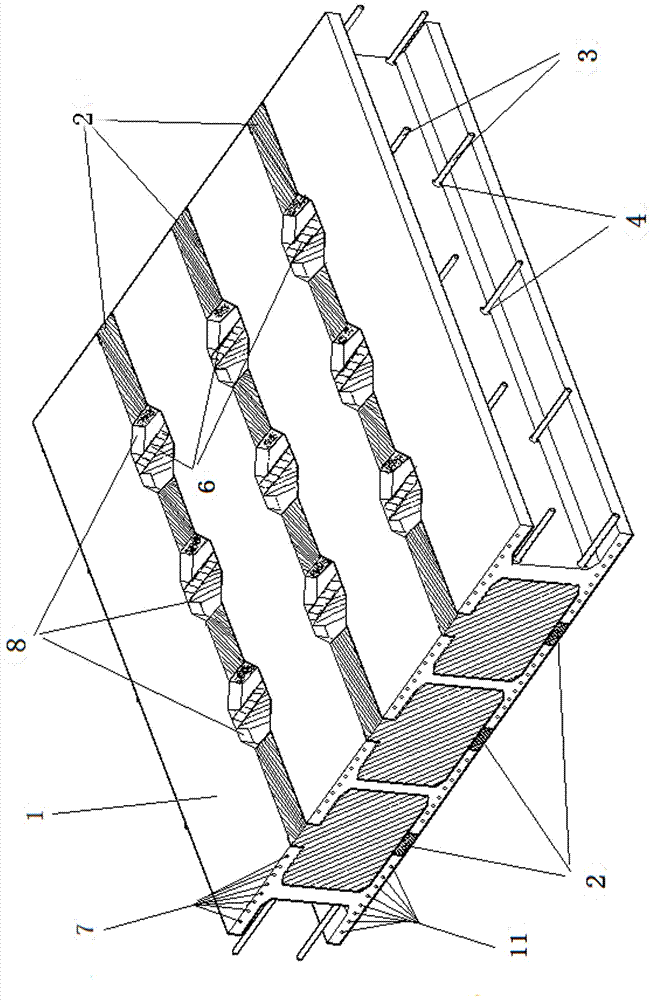

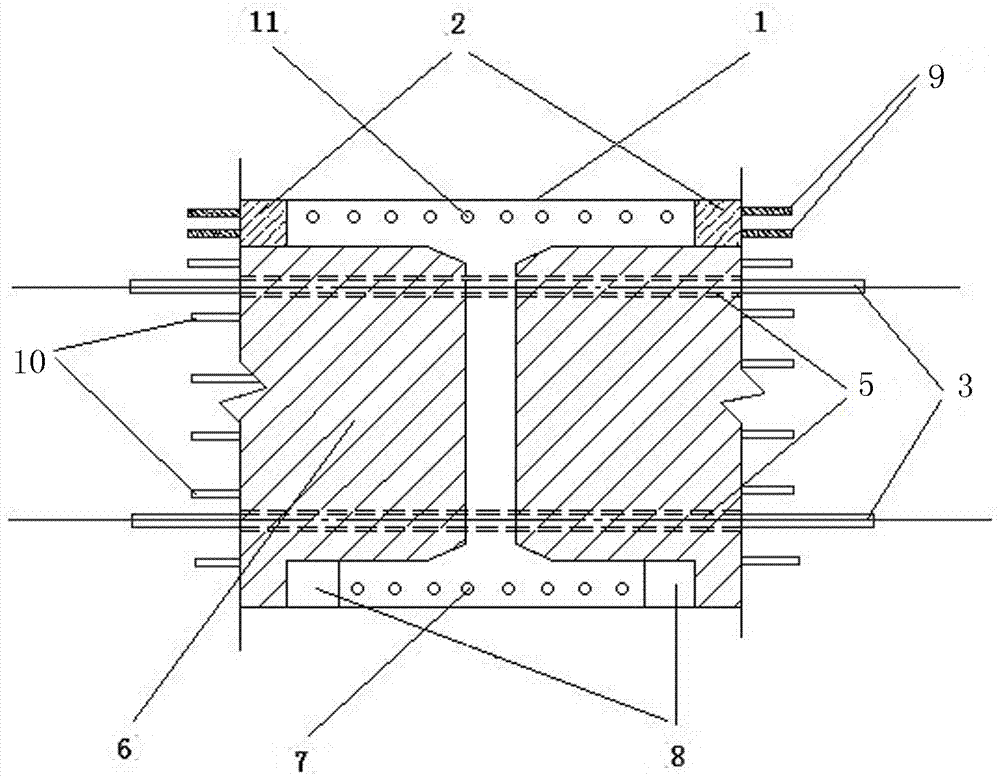

[0019] Figure 1~5 Middle, 1. I-beam; 2. Wet joint concrete; 3. Transverse prestressed tendon; 4. Anchorage; 5. Reserved tunnel; 6. Concrete diaphragm; 7. Longitudinal prestressed tendon; Reserved holes; 9. Wet joint connection reinforcement; 10. Concrete diaphragm connection reinforcement; 11. Longitudinal common reinforcement.

[0020] Depend on Figure 1 to Figure 5 It can be seen that the transverse prestressed I-shaped box girder structure is composed of a plurality of I-beams 1. Wet the joint concrete 2 between the I-beam roofs, and set the wet joint connecting steel bar 9 at the outer end of the I-beam roof; Transverse prestressed tendons 3 are set in the channel, and the two ends of the transverse prestressed tendons are anchored by anchors 4; the joint concrete 2 is also humidified at the joint of the bottom plates of the two I-beams, and the above-mentioned con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com