Construction method for widening and ribbing heavy-thickness sub-base of cold-plateau highway

A construction method and sub-base technology, applied in the direction of roads, roads, pavement details, etc., to achieve the effect of enhancing bearing capacity, enhancing integrity, and improving stress characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

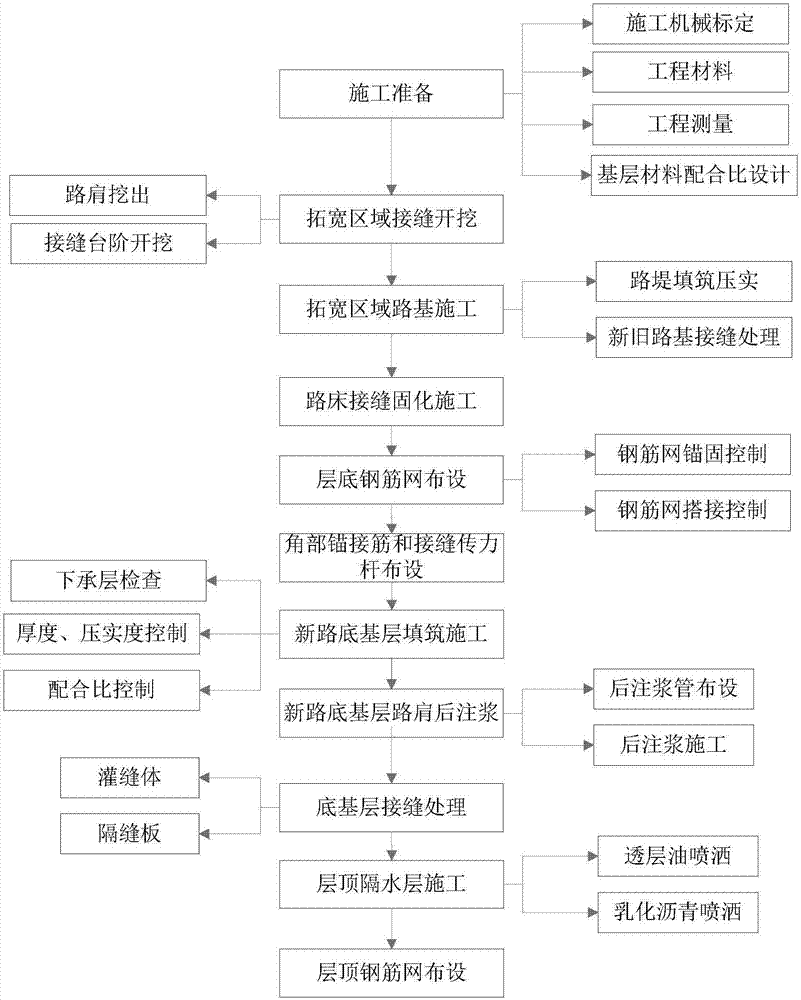

[0036] In this embodiment, the mix ratio design of the new road subbase, the old road subbase, and the old road subbase, the technical requirements for the construction of paving and rolling, the technical requirements for the construction of corner anchor bars and joint dowel bars, and the production of partition boards And technical requirements for installation and construction, construction technical requirements for joint filling, etc. will not be described in detail in this embodiment, and the implementation methods related to the construction method of the present invention will be focused on.

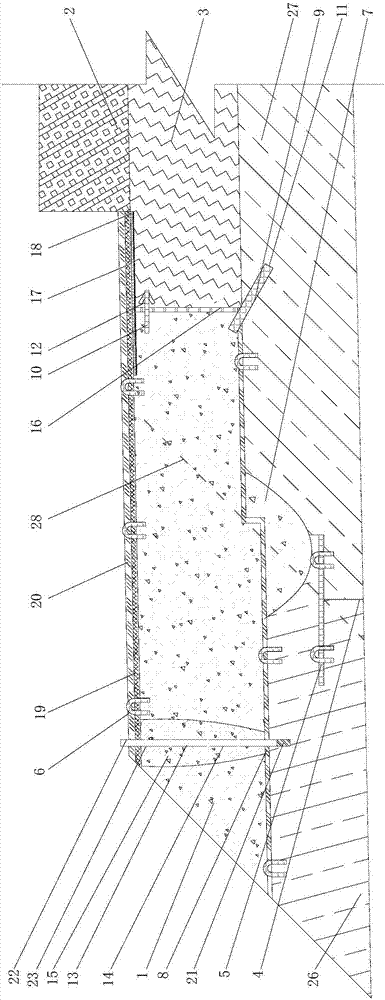

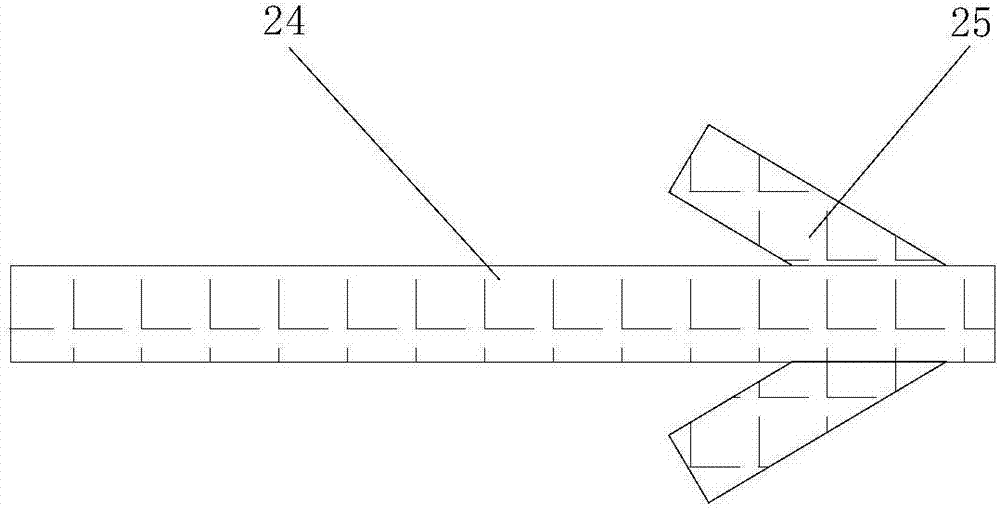

[0037] figure 1 It is a schematic diagram of the structure of the widened and reinforced large-thickness subbase of the highway in the alpine region of the present invention. figure 2 yes figure 1 Schematic diagram of the cross-section of the joint dowel bar. refer to Figure 1 ~ Figure 2 As shown, the present invention relates to the broadened and reinforced large-thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com