A prefabricated bearing pier structure and its construction method

A technology for prefabricated piers and prefabricated plants, which is applied in infrastructure engineering, construction, sheet pile walls, etc., can solve the problems of complicated construction steps and difficult construction quality control, and achieves increasing the surface area of the pier side, saving consumption, and improving integrity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

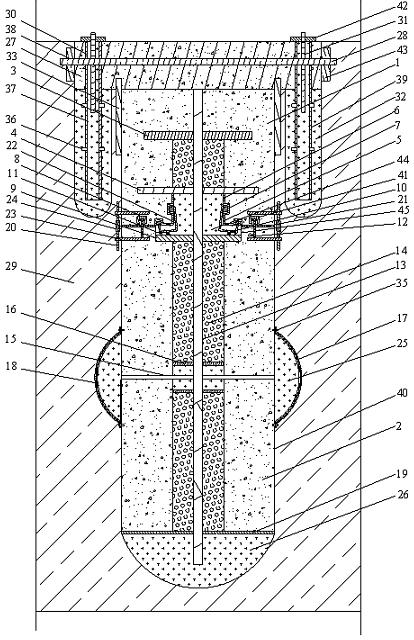

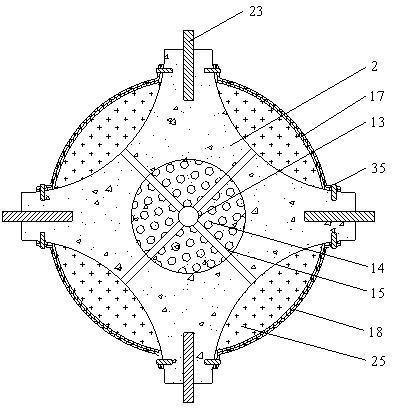

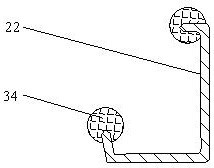

[0044] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

[0045] Regarding the preparation and construction technical requirements of the pier top platform, the prefabricated pier connection section and the lower precast pier, the technical requirements for grouting construction, the technical requirements for concrete mix ratio design and pouring, and the technical requirements for prestressed tendon tensioning construction, etc., in this embodiment No more details will be given, and the following will focus on the implementation of the structures involved in the present invention.

[0046] like Figures 1 to 4 Shown is a structural schematic diagram of a prefabricated bearing pier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com