A prefabricated beam and prefabricated column connection structure and construction method

A technology for connecting structures and assembling columns, which is applied in the direction of building construction and construction, and can solve problems such as dense arrangement of steel bars at the lower part of beams, difficulty in construction, difficulty in pouring concrete, and loss of bearing capacity of concrete nodes. Effects of shear resistance, impact reduction, and improved seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

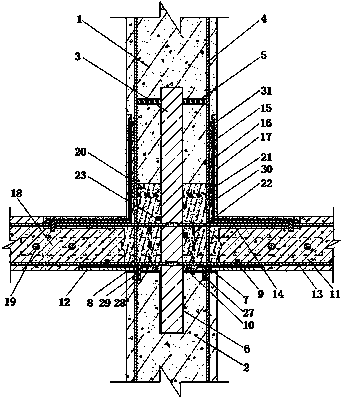

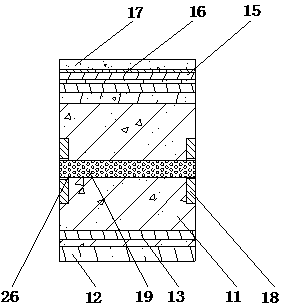

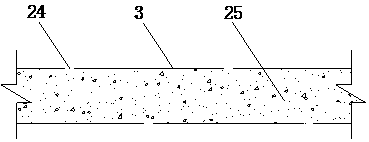

[0036] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

[0037] The design and construction technical requirements of the upper assembly column and the lower assembly column, the design and construction technical requirements of the assembly beam, the on-site welding construction technical requirements, the post-cast concrete design and construction technical requirements, the interface bonding layer laying construction technical requirements, etc. The description will not be repeated in the implementation manner, and the implementation manner related to the structure of the present invention will be focused on.

[0038] figure 1 It is a schematic cross-sectional view of the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com