Polymer material grouted wedge precast pile construction method

A construction method and polymer technology, which are applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of being limited by the condition of cement slurry, difficult to connect grouting pipes, and unable to be recycled and reused. Achieve the effects of being beneficial to environmental protection and energy saving, improving the overall stress characteristics of the pile, and improving the form of the contact surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

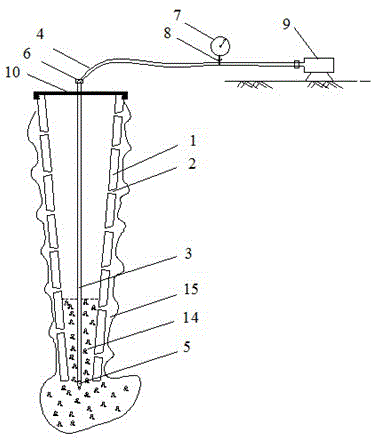

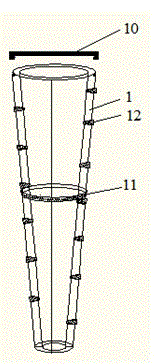

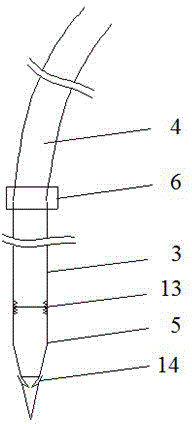

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The protection scope of the present invention is not limited only to the description of this embodiment.

[0021] like figure 1 and figure 2 As shown, when implementing, firstly, the pile driver is in place, and the prefabricated prestressed wedge-shaped pipe pile pipe joint 1 is statically pressed to the design depth by using the static pressure pile machine. The position of the pre-press grouting hole 2 is blocked with a wedge-shaped wooden plug 12, which is automatically flushed open during pressure grouting; after the static pressure sinks a section of pipe joint 1, the two prestressed The wedge-shaped pipe joint 1 is connected and statically pressed to the design depth; the bottom end of the rigid grouting pipe 3 is connected with the grouting drill bit 5 through the drill bit threaded joint 13, and the drill bit grouting port valve 14 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com