Prestressed concrete pole as well as mold and manufacturing method thereof

A prestressing and concrete technology, applied in the field of power transmission, can solve the problems of main reinforcement eccentricity, large stress loss, and pole cracks, and achieve the effect of preventing longitudinal cracks and no prestress loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

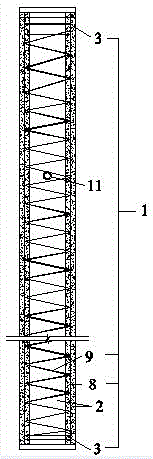

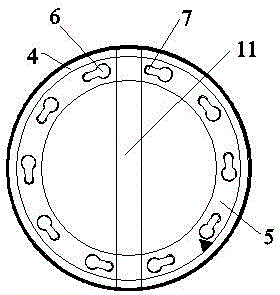

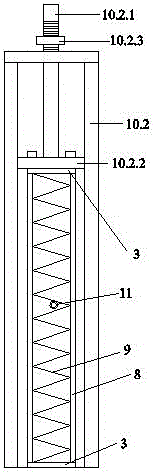

[0017] exist Figure 1 to Figure 4 Among them, this prestressed concrete pole includes a steel frame 1 and concrete 2, and it is characterized in that the steel frame 1 includes end plates 3 at both ends, and the end plates 3 are composed of steel rings 4 and anchor plates 5, The anchoring disc 5 is provided with tensioning screw holes 6 evenly distributed on the circumference of the anchoring disc 5, and the anchoring disc 5 is provided with a prestressed main tendon hole 7 beside the tensioning screw hole 6, and the prestressed main rib hole 7 and the tensioning screw hole 6 In the same way, the prestressed main reinforcement hole 7 is longitudinally installed with the prestressed main reinforcement 8, and the prestressed main reinforcement 8 is welded with a spiral reinforcement 9, and a steel pipe 11 is embedded in the horizontal direction in the reinforcement skeleton 1, and concrete is poured in the reinforcement skeleton 1, and the concrete adopts P.o52.5 grade cement, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com