Method for stimulating continuous casting crystallizer to perform non-sinusoidal vibration by swing type eccentric shaft

A continuous casting crystallizer and eccentric shaft technology, which is applied in the field of continuous casting, can solve problems such as unsuitable adjustment of crystallizer amplitude, inability to adjust amplitude on-line, and difficulty in eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

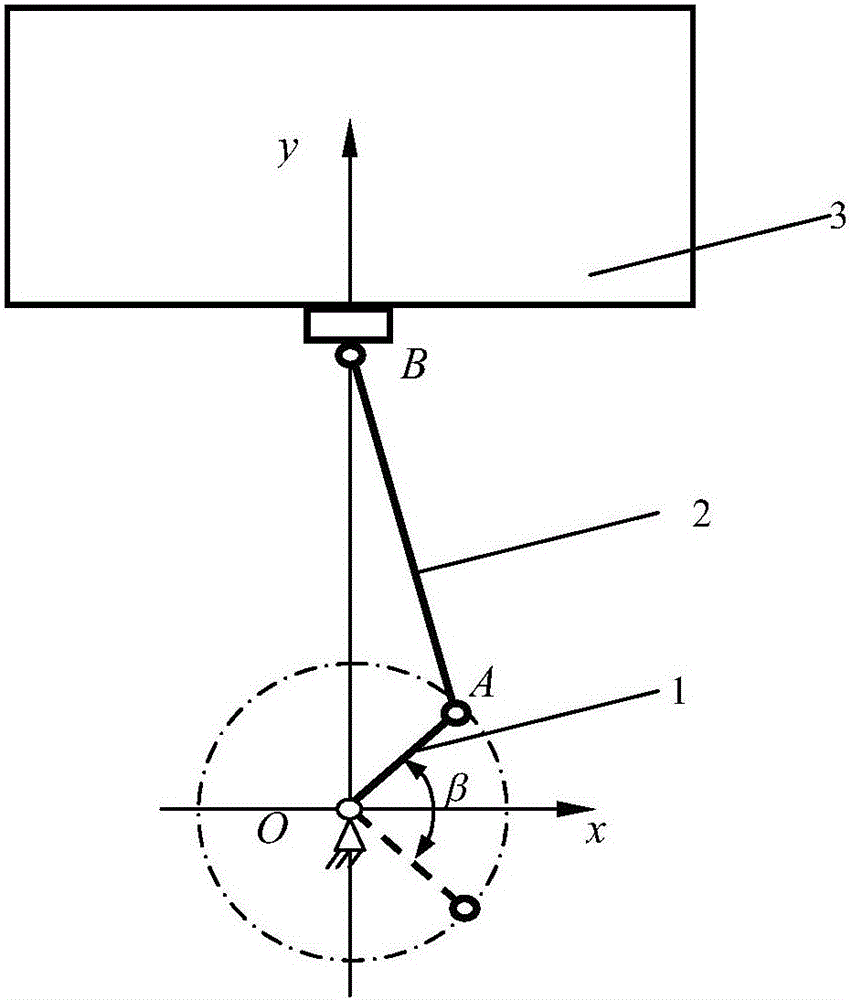

[0061] Such as figure 1 As shown, the eccentric shaft 1 is simplified to crank OA, the eccentric distance e of the eccentric shaft is the same as the length of OA, the connecting rod 2AB is respectively hinged with the eccentric shaft and the crystallizer vibrating table 3, the vibrating table moves along a specific track through the guide device, and the crystallizer is fixed On the vibrating table, move with the vibrating table. The crank OA swings symmetrically about the horizontal axis x, the maximum value of the swing angle β is 180°, and the point B moves vertically along the y-axis.

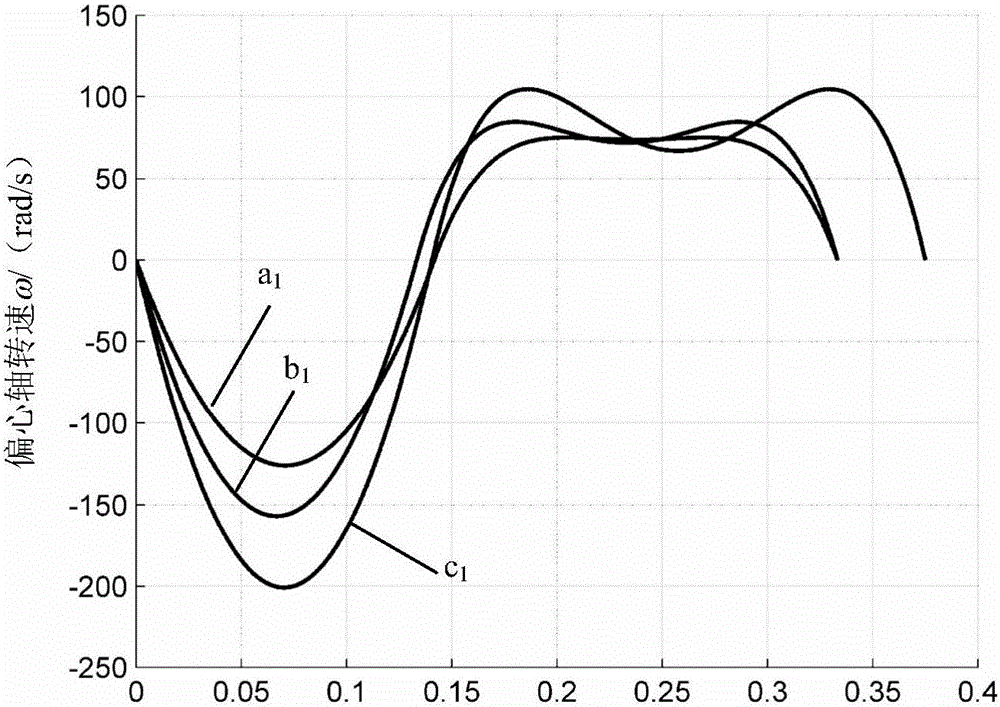

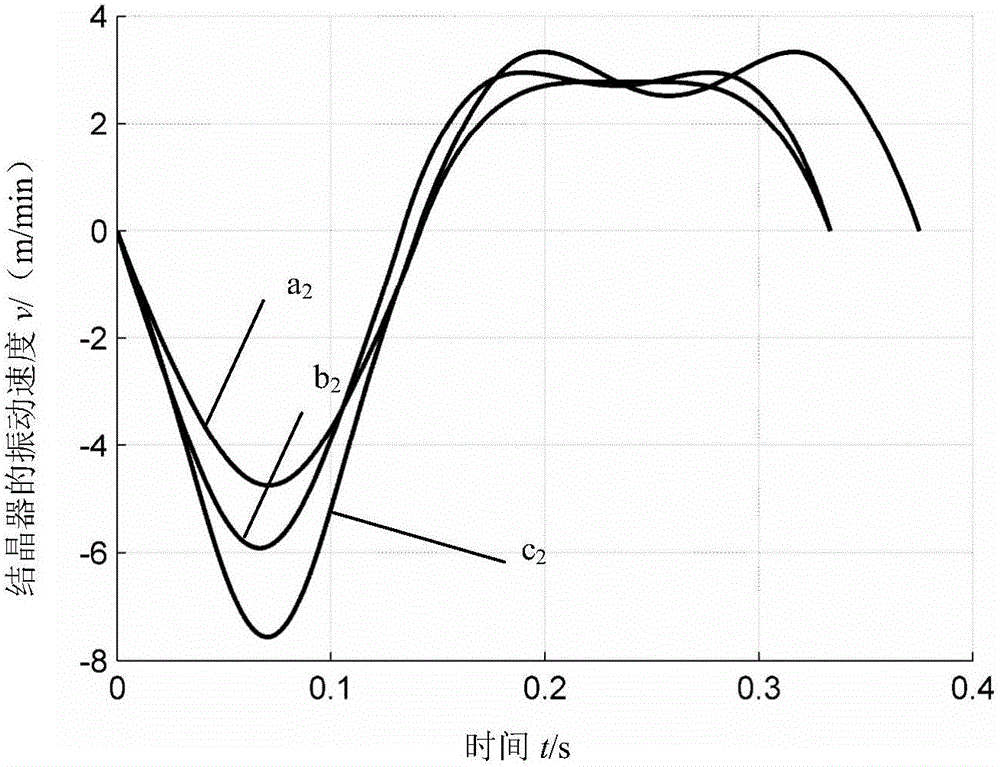

[0062] This example is aimed at figure 1 According to the three basic vibration parameters of the crystallizer, amplitude h, frequency f and waveform skew rate α, the corresponding non-sinusoidal waveform is designed. Since the vibration parameters should be adjusted with the change of working conditions and steel types in production, three groups of vibration parameters suitable for dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com