Pipe externally-circumferential weld scanner

A scanner and outer ring technology, applied in the field of robots, can solve the problems of huge pipeline flaw detection engineering, high price, complicated design of pipeline ultrasonic detection device, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

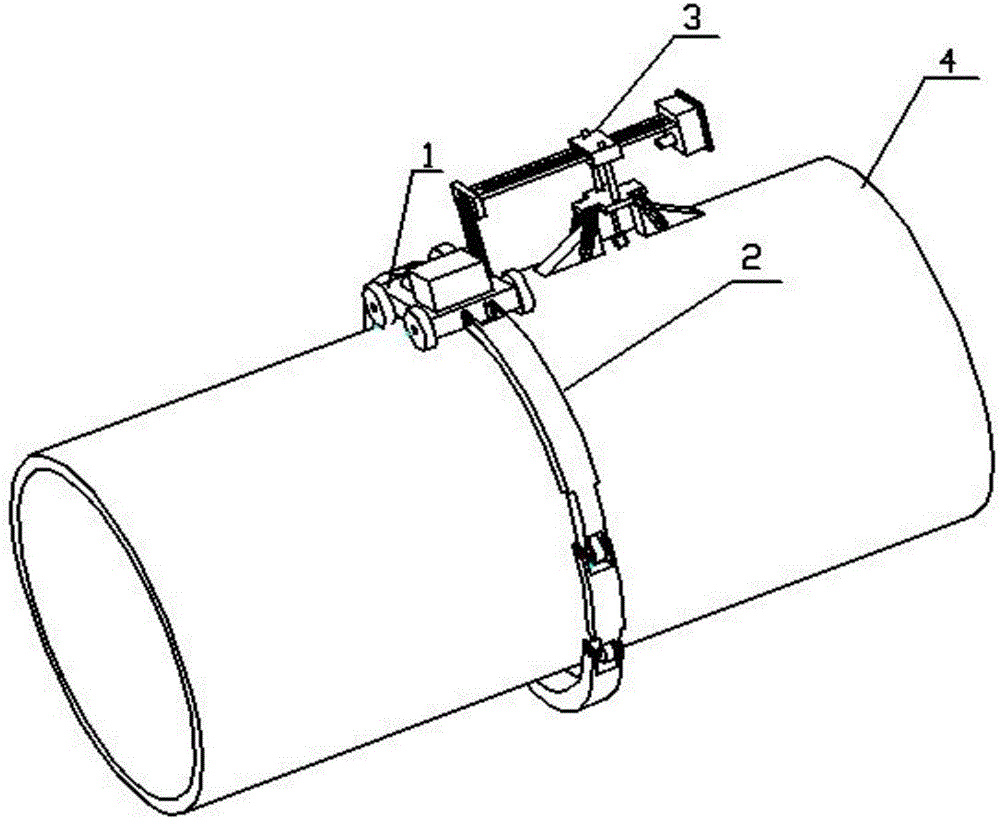

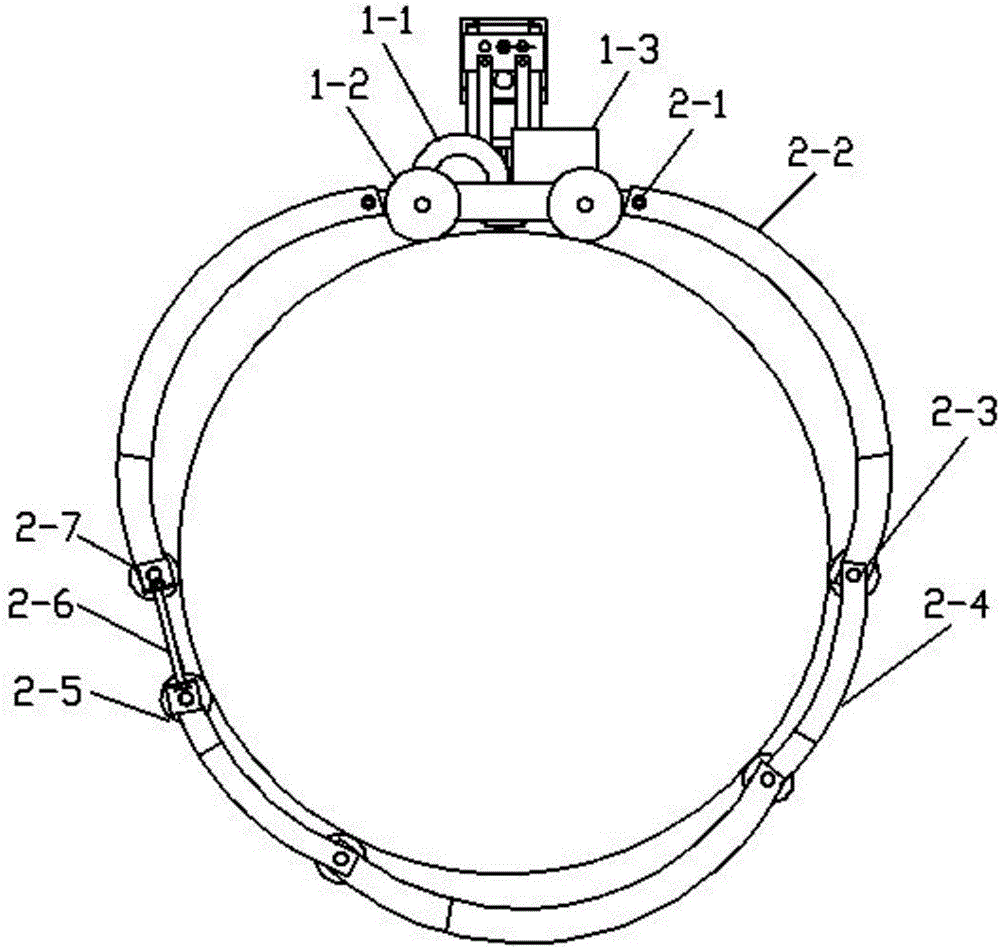

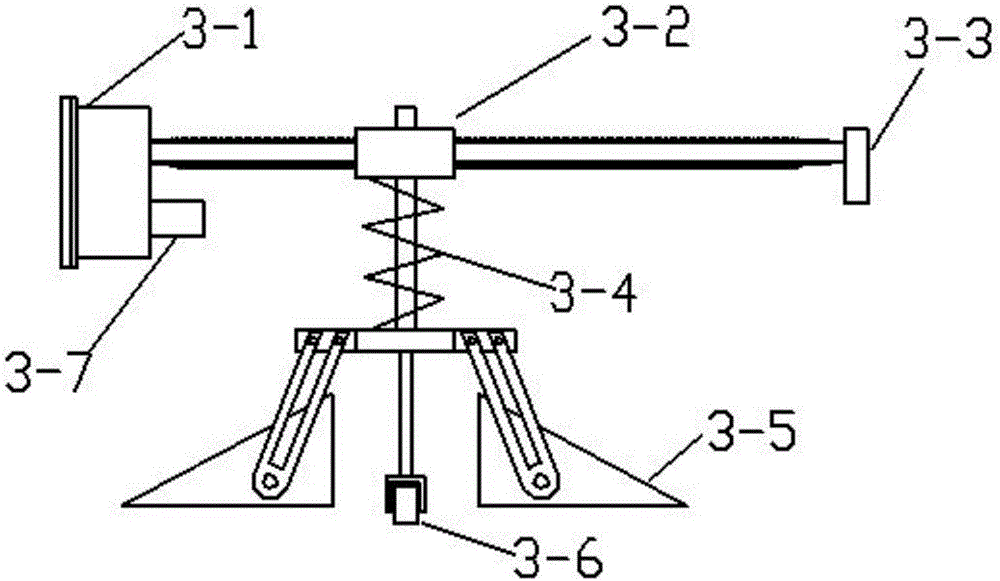

[0018] Such as figure 1 , 2 As shown in and 3, the pipe outer ring weld seam scanner is mainly composed of a driving car assembly 1, a chain walking mechanism 2 and a probe adjustment mechanism 3. The driving car assembly 1 comprises a car body, a driving motor 1-1, a wheel 1-2 and a control box 1-3; four wheels 1-2 are arranged on both sides of the car body; the driving motor 1-1 and the control box 1-3 are all It is fixed on the car body; the drive motor 1-1 drives the wheel 1-2 through the gear reducer, so that the drive car assembly 1 moves along the pipeline 4 in the circumferential direction; the control box 1-3 controls the start and stop of the drive motor 1-1.

[0019] Such as figure 2 As shown, the chain walking mechanism 2 includes a pin 2-1, a long chain link 2-2, a chain link bolt 2-3, a short chain link 2-4, a roller 2-5, an adjusting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com