Novel vibration frequency sensor system based on voltage multiplier

A voltage multiplier and vibration frequency technology, applied in the field of sensors, can solve problems such as the inability to directly reflect the vibration frequency, increase the cost of use, redundancy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

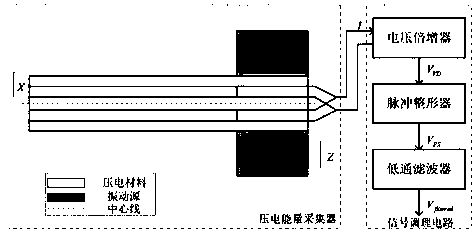

specific Embodiment approach

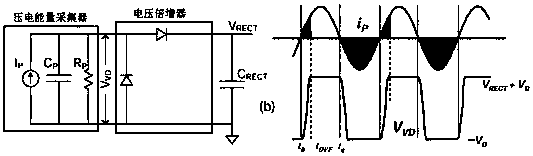

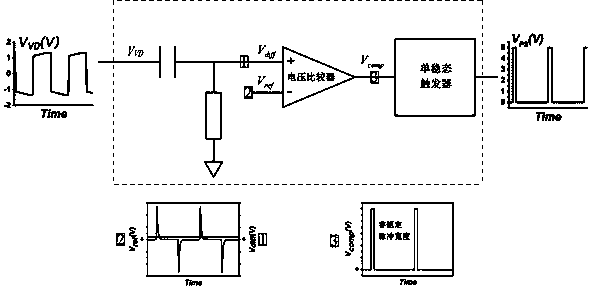

[0038] The specific implementation method is as follows: the function signal generator produces a standard sinusoidal signal, and after being amplified by the power amplifier, it acts on the vibrating table; the vibrating table will carry out regular sinusoidal vibration; Influence, based on the piezoelectric effect, the piezoelectric material on the upper and lower layers of the piezoelectric cantilever will be stretched or compressed due to vibration, forming a sinusoidal output current. The output current first passes through the voltage multiplier. When the current passes through zero or the sign changes, the output voltage of the voltage multiplier will change to track the vibration frequency. The output voltage of the voltage multiplier passes through the pulse shaper and low-pass filter, the pulse width is fixed and filtered, and the DC component that can reflect the vibration frequency is obtained and displayed on the digital oscilloscope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com