Device used for dynamic and static calibration of eddy current sensor

An eddy current sensor, dynamic and static technology, applied in the direction of using electrical devices, measuring devices, using electromagnetic means, etc., can solve the problems of complex mechanical structure, narrow frequency range of dynamic calibration, difficult to achieve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

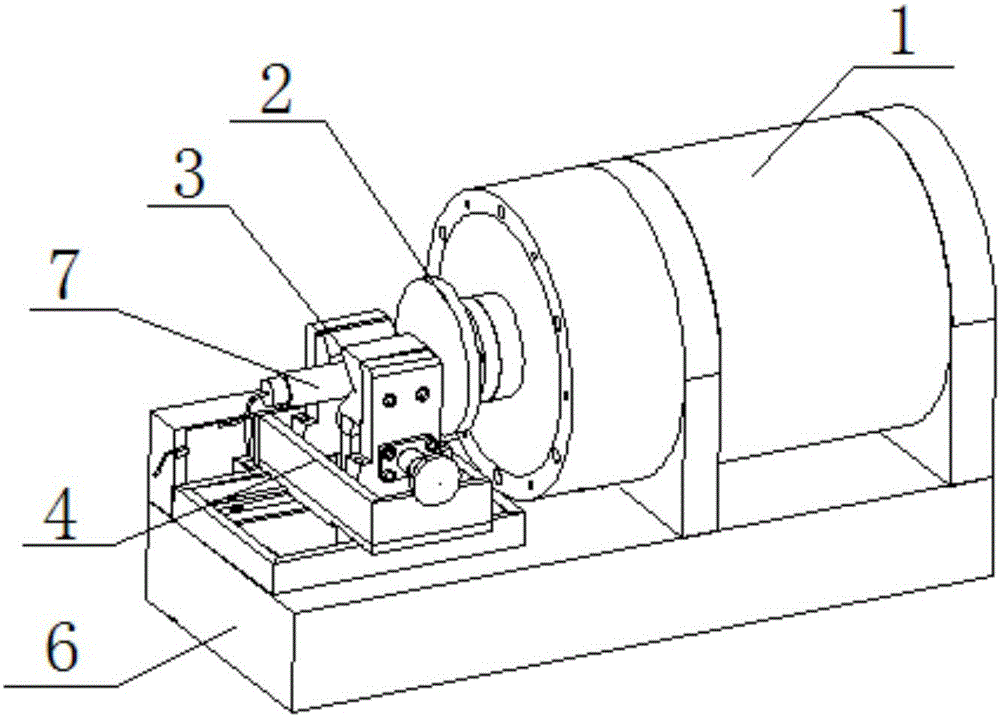

[0033] Such as figure 1 As shown, the dynamic and static automatic calibration device of the eddy current sensor includes a vibration table module 1, an induction plate 2 connected to the work surface of the vibration table, a standard acceleration sensor 5 connected to the work surface, a sensor fixture 3, a motion execution module 4 and a fixed vibration table And the base 6 of the motion execution module.

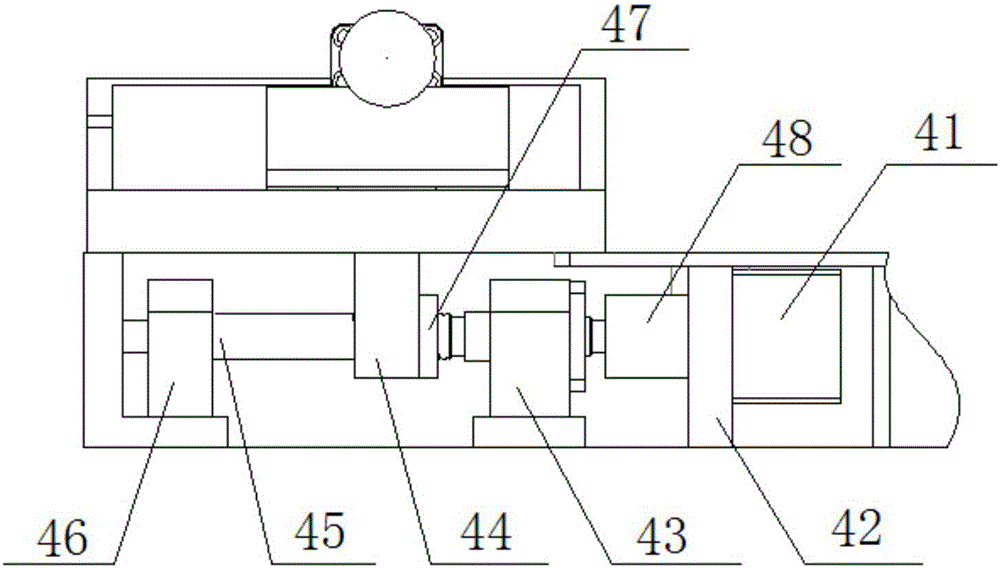

[0034] The motion execution module is composed of a positioning drive assembly that drives the clamp to move radially along the induction disk 2 and a calibration drive assembly that drives the clamp to move axially along the induction disk 2 .

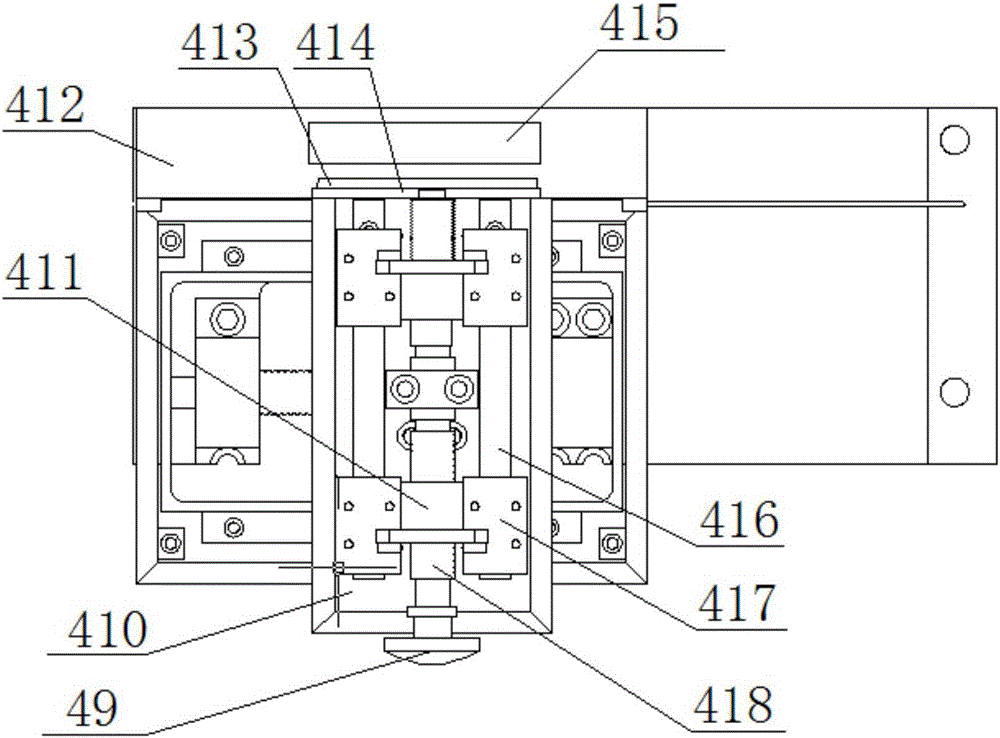

[0035] The position adjustment drive assembly includes the combination of the first lead screw mechanism and the guide rail 416-slider 417; the fixture is fixed on the slide block 417 of the guide rail 416-slider 417 combination; To be parallel, the guide rail 416 is parallel to the first lead screw 418 of the first lead screw me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com