Method and system for predicting random vibration life of PCB solder point

A fatigue life prediction, random vibration technology, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve accurate prediction results, accurate data acquisition, and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

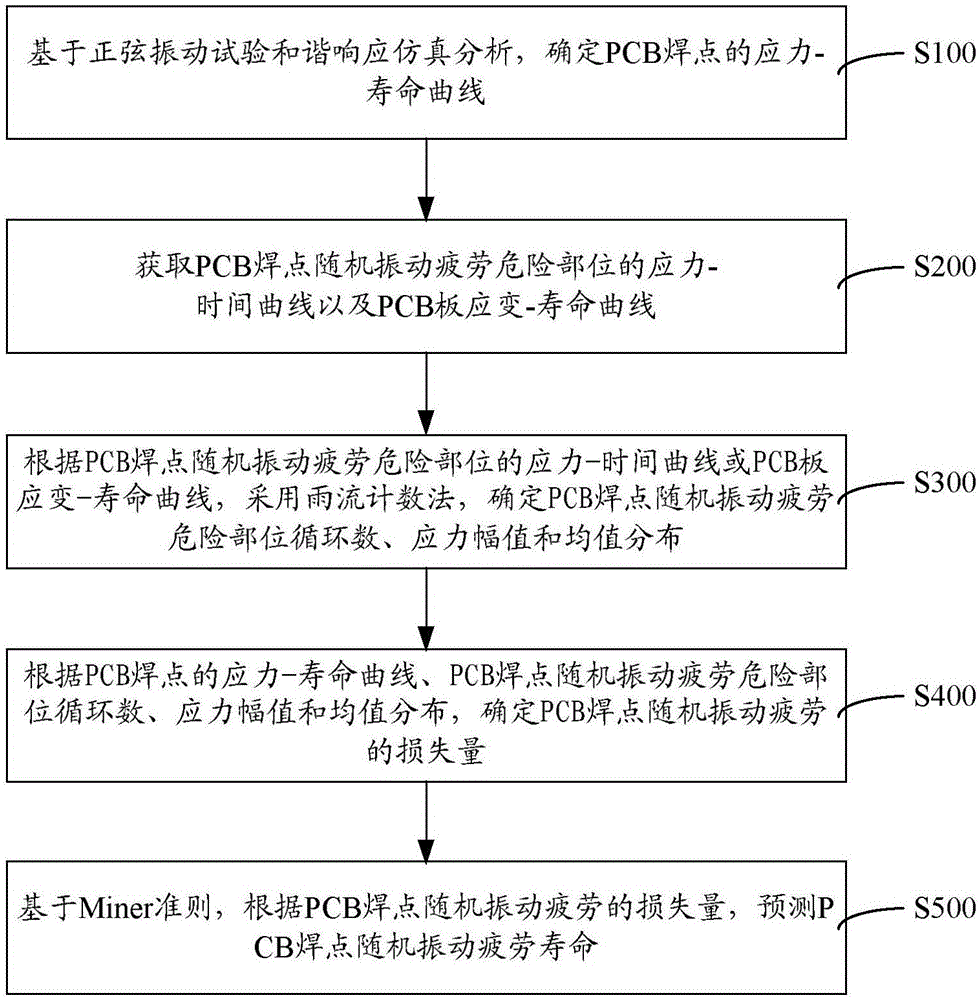

[0025] Such as figure 1 As shown, a random vibration fatigue life prediction method for PCB solder joints includes steps:

[0026] S100: Based on the harmonic response simulation analysis of the sinusoidal vibration test, determine the stress-life curve of the PCB solder joint.

[0027] The stress-life curve of PCB solder joints can be obtained based on historical data simulation analysis, or real-time data collection simulation analysis.

[0028] In one of the embodiments, step S100 may include:

[0029] Step 1: Conduct a static simulation experiment on the PCB to obtain the main frequency and formation of each order of the PCB components;

[0030] Step 2: Taking the first-order main frequency as the center frequency, apply acceleration excitations of different magnitudes, conduct sinusoidal vibration tests, record the failure time of solder joints under acceleration excitations of different magnitudes, and calculate the number of solder joint failure cycles;

[0031] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com