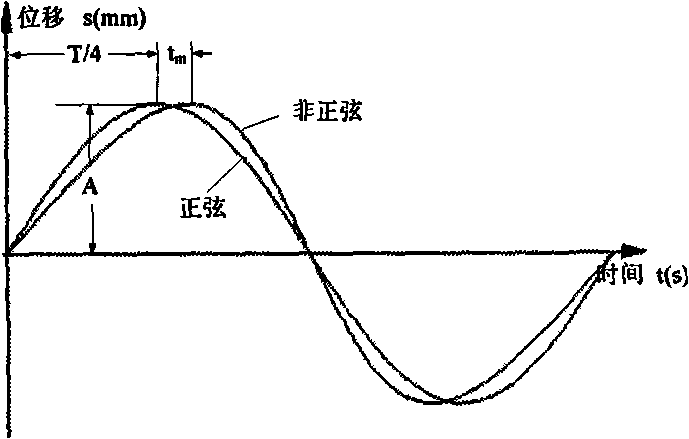

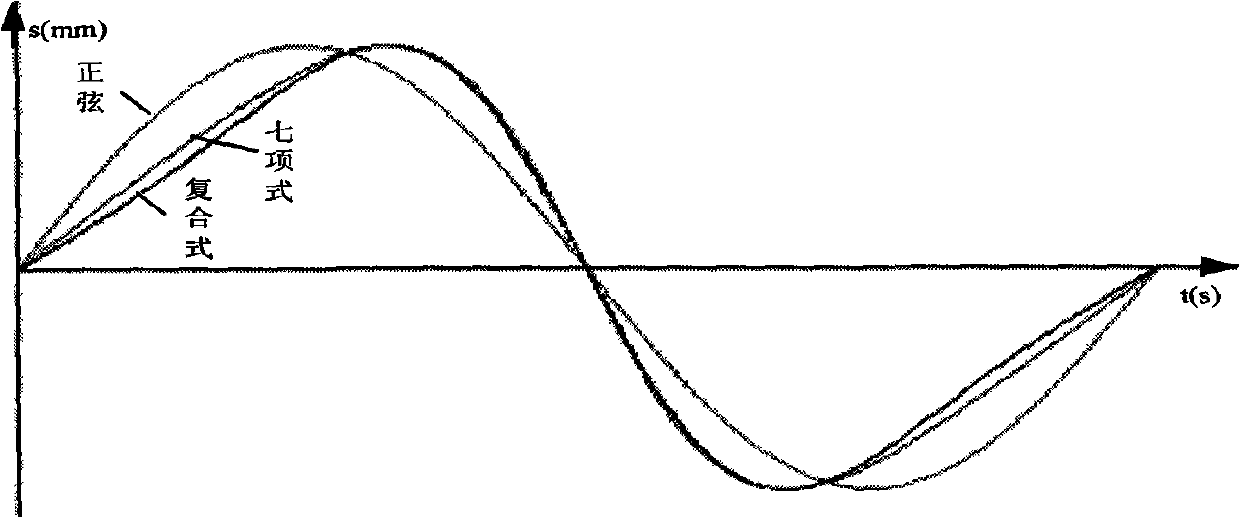

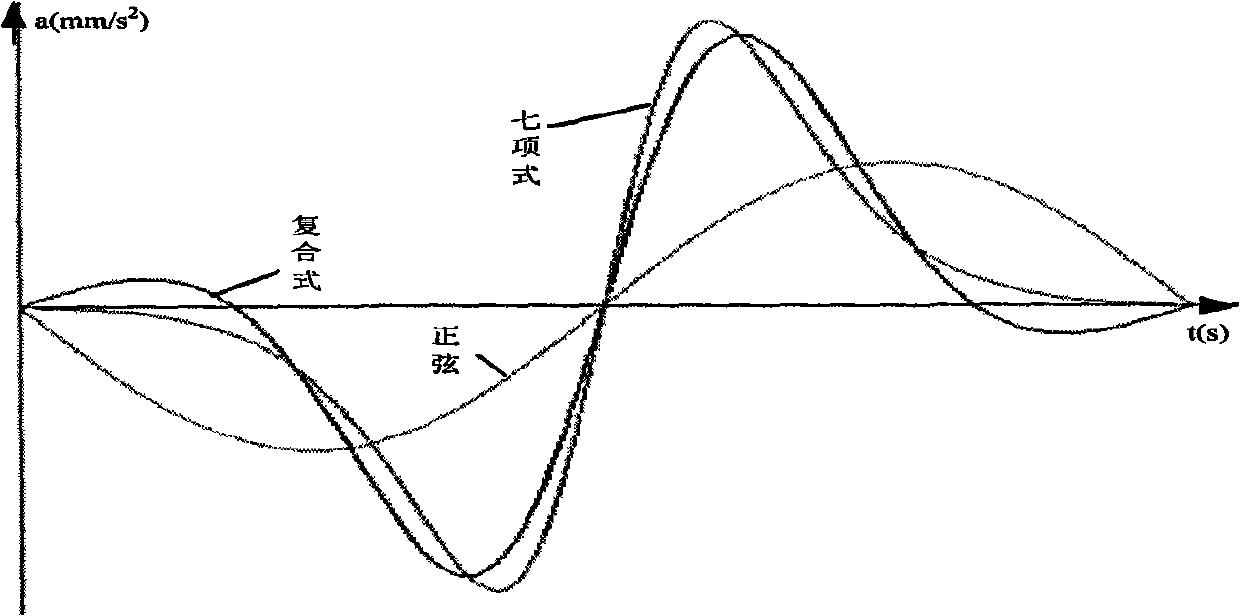

Non-sinusoidal waveform generator used for mold oscillation

A waveform generator and crystallizer vibration technology, which is applied in the direction of instruments, mechanical oscillation control, non-electric variable control, etc., can solve the problems of acceleration deformation, equipment flutter, and the deflection rate should not be too large, so as to reduce vibration marks and equipment Smooth operation and improved surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the invention will be further described:

[0025] A non-sinusoidal waveform generator for crystallizer vibration, including: a signal input module: used to input the amplitude, frequency, and skew rate of the non-sinusoidal waveform; three parameters are determined, and a curve is defined. Waveform generation module: It receives the amplitude, frequency, and skew rate of the signal input module, and generates corresponding waveforms; the waveform generation module performs the following functions:

[0026] s = A h x Σ m = 1 n ( - Δ ) ( m - 1 ) Sin ( mωt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com