Decoupled three-degree-of-freedom forced vibration system for bridge section model

A vibration system and forced vibration technology, applied in aerodynamic tests, measuring devices, instruments, etc., can solve the problems of poor vibration waveform accuracy, difficult decoupling, large span, etc., and achieve good real-time performance and accurate test data Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

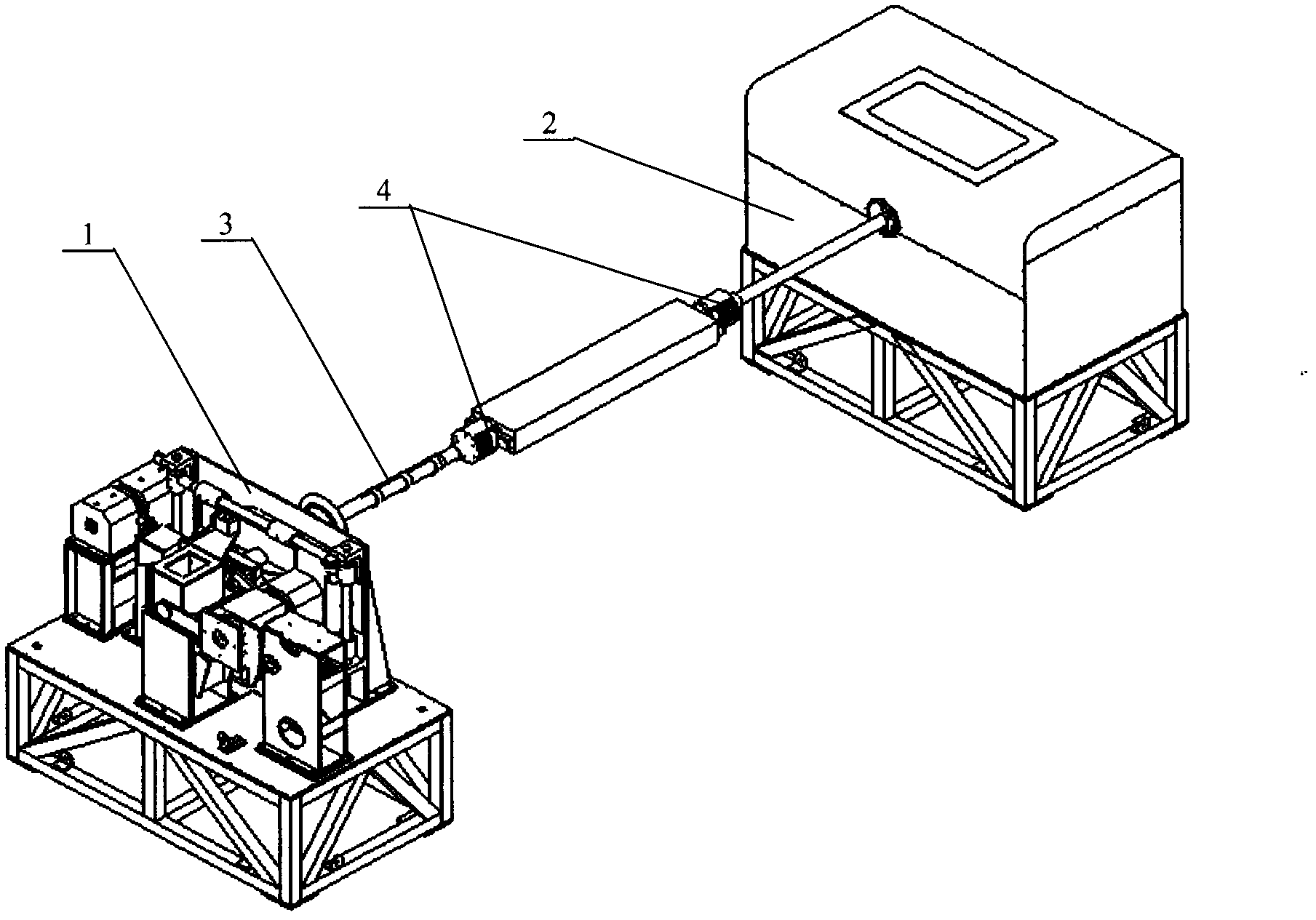

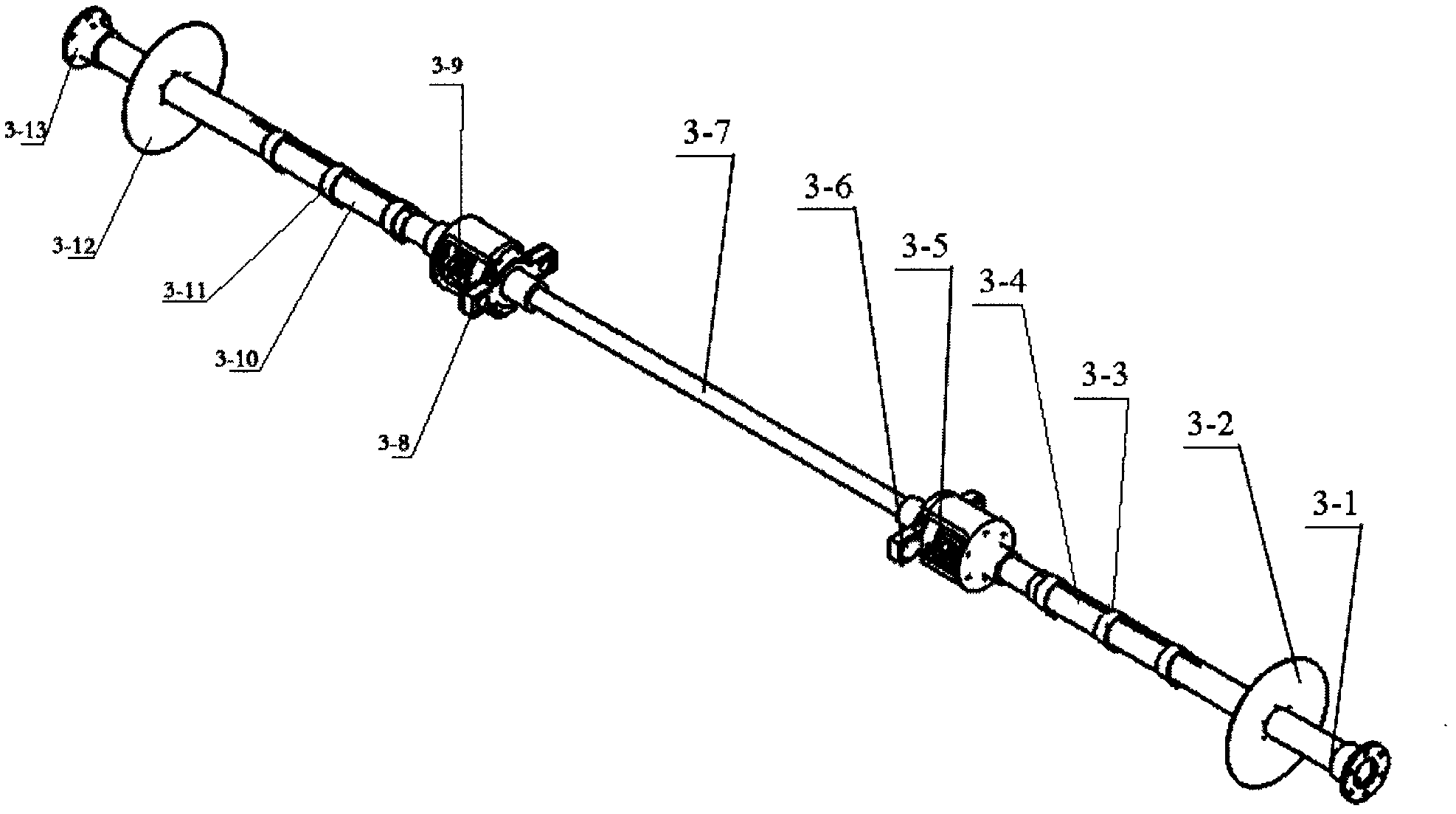

[0027] Embodiment 1: (see Figure 1 to Figure 9 ) degree-of-freedom bridge segment model forced vibration system, which consists of an outer vibration system (1), an inner vibration system (2), a model support system (3) and a detection system (4). The outer vibration system (1) and the inner vibration system (2) are symmetrically arranged on both sides of the wind tunnel, the bridge segment model is connected to the model support system (3) through the detection system (4), the outer vibration system (1) and the inner vibration system The system (2) vibrates synchronously under the drive of the servo motor, so as to realize the three-degree-of-freedom forced vibration of the bridge segment model. figure 1 The middle and outer vibration system (1) is not equipped with a shell.

Embodiment 2

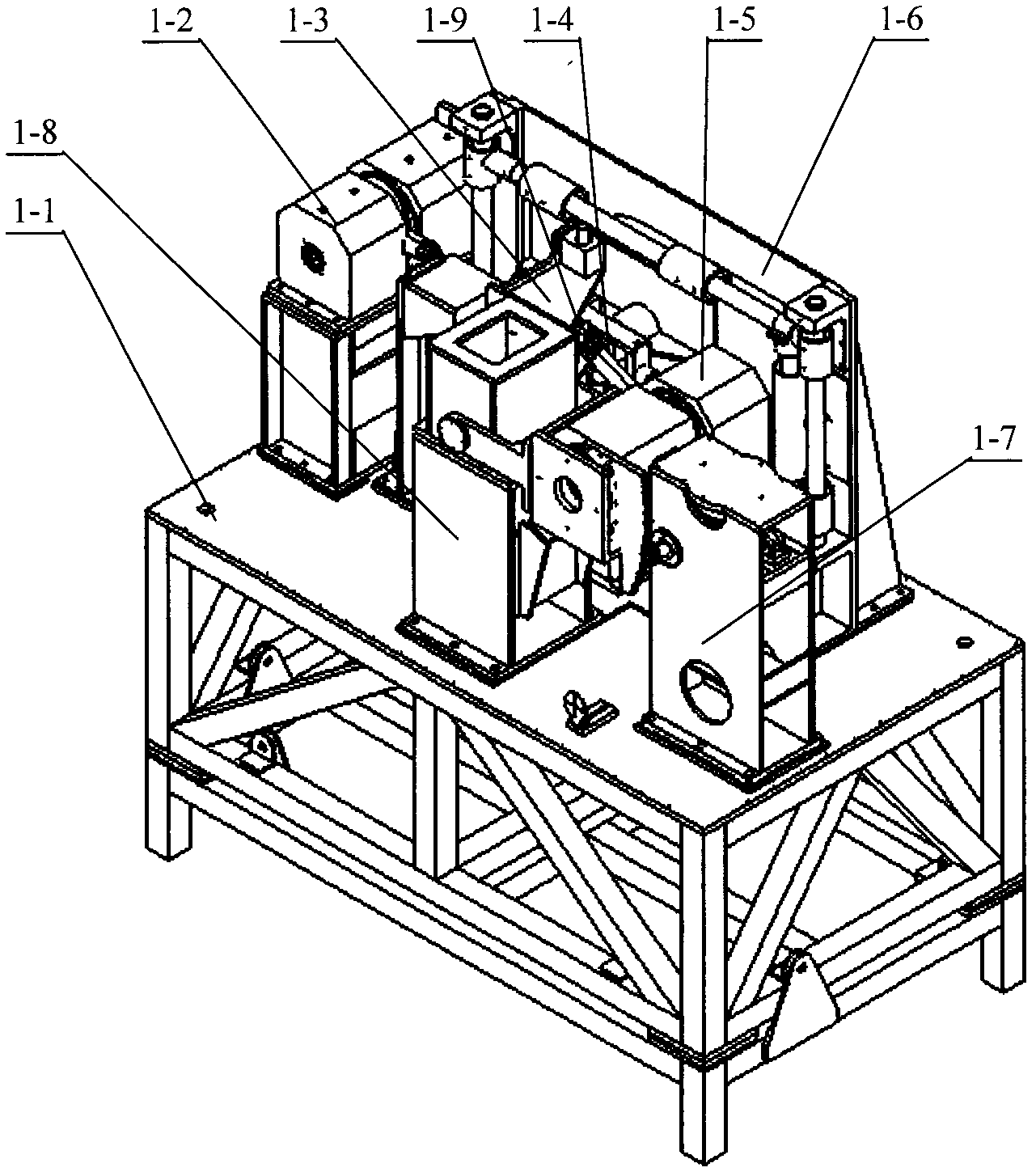

[0028] Embodiment 2: (see Figure 2 to Figure 9 ) The outer vibration system (1) consists of a frame (1-1), a horizontal vibration slider crank mechanism (1-2), a vertical vibration slider crank mechanism (1-3), a torsional vibration crank rocker mechanism (1- 5), XY motion composite mechanism (1-4), small wheel support type Oldham coupling (1-9), XY sliding bracket (1-6), locking mechanism (1-7) and angle of attack adjustment Organization (1-8) composition. The horizontal vibration crank slider mechanism (1-2) consists of eccentric wheel type adjustable crank (1-2-1), connecting rod (1-2-2), Y-shaped push rod (1-2-4), horizontal vibration Linear bearing seat (1-2-3) and horizontal vibration support (1-2-5), horizontal vibration linear bearing seat (1-2-3) and horizontal vibration support (1-2-5) are fixed on the frame On (1-1), the sinusoidal vibration in the horizontal direction is output under the drive of the servo motor; the vertical vibration crank slider mechanism (1-...

Embodiment 3

[0029] Embodiment 3: (see figure 1 ) The corresponding parts of the inner vibrating system (2) are mirror-image symmetrical with the corresponding parts of the outer vibrating system (1) in terms of shape and installation position, and the transmission principle is exactly the same, synchronously vibrating under the drive of the servo motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com