Method for controlling fine cracks on surface of sub-peritectic steel bar

A peritectic and small technology, applied in the field of iron and steel production, can solve the problems of reducing production efficiency, product scrapping, and serious small cracks on the surface of bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Production of sub-peritectic low-alloy steel, the cross-sectional size of the continuous casting slab is 260mm×300mm, hot-rolled into a bar with a specification of Φ110mm, because there are small cracks on the surface of the bar with a depth greater than 2mm, the pass rate of flaw detection is only 42.7%, in order to reduce the bar Small cracks on the surface to increase the pass rate, the specific implementation measures are as follows:

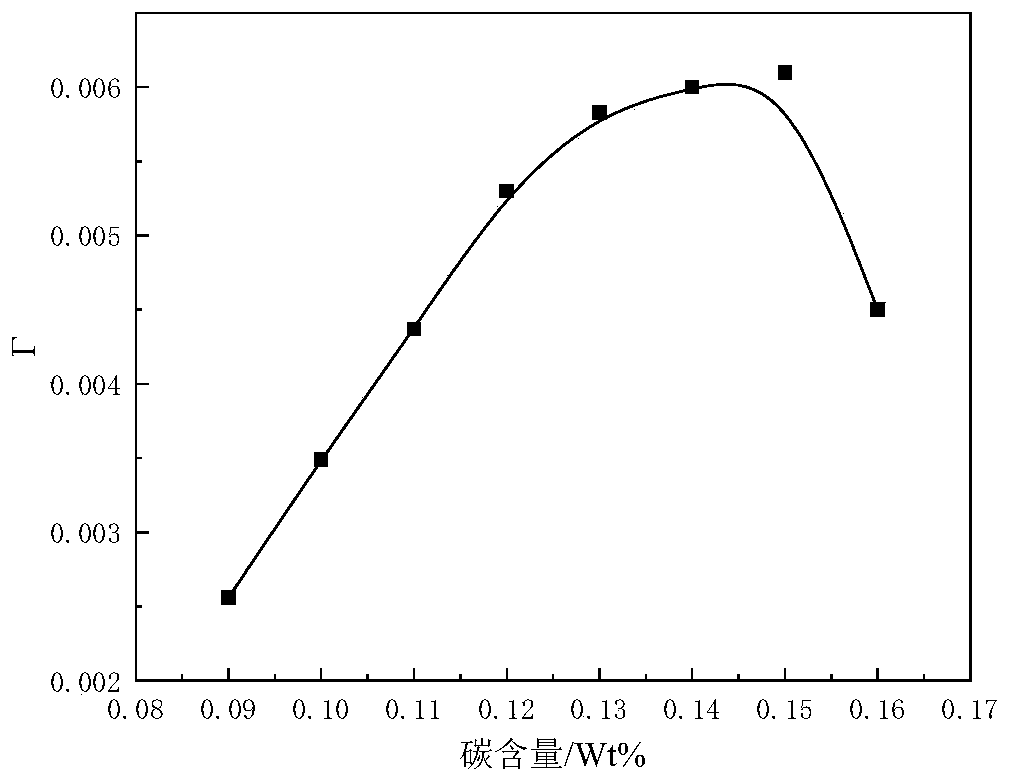

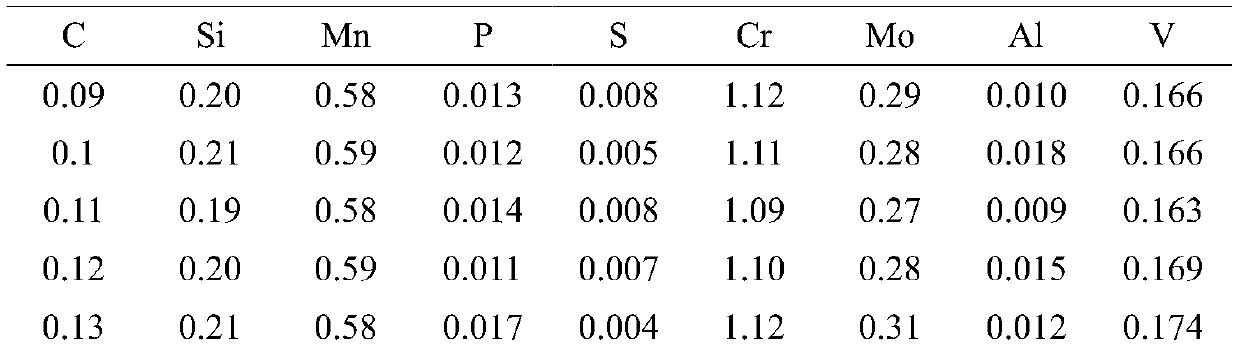

[0030] The chemical composition of the hypoperitectic low alloy steel was collected and produced, as shown in Table 1. The relationship between the shrinkage rate (Γ) of the peritectic reaction body in the brittle temperature zone (LIT~ZDT) and the carbon content of molten steel was calculated and analyzed through the phase diagram. The calculation results are as follows figure 1 shown. according to figure 1 As a result, the carbon component whose shrinkage ratio Γ of the peritectic reaction body is less than 0.004 is selected as 0.0...

Embodiment 2

[0037] Production of sub-peritectic ordinary carbon steel, continuous casting slab section size 200mm×200mm, hot rolled into bars with a specification of Φ90mm, because there are small cracks with a depth greater than 2mm on the surface of the bars, the pass rate of flaw detection is 51.6%, in order to reduce sub-packages Small cracks on the surface of crystal steel bars increase the pass rate. The specific implementation measures are as follows:

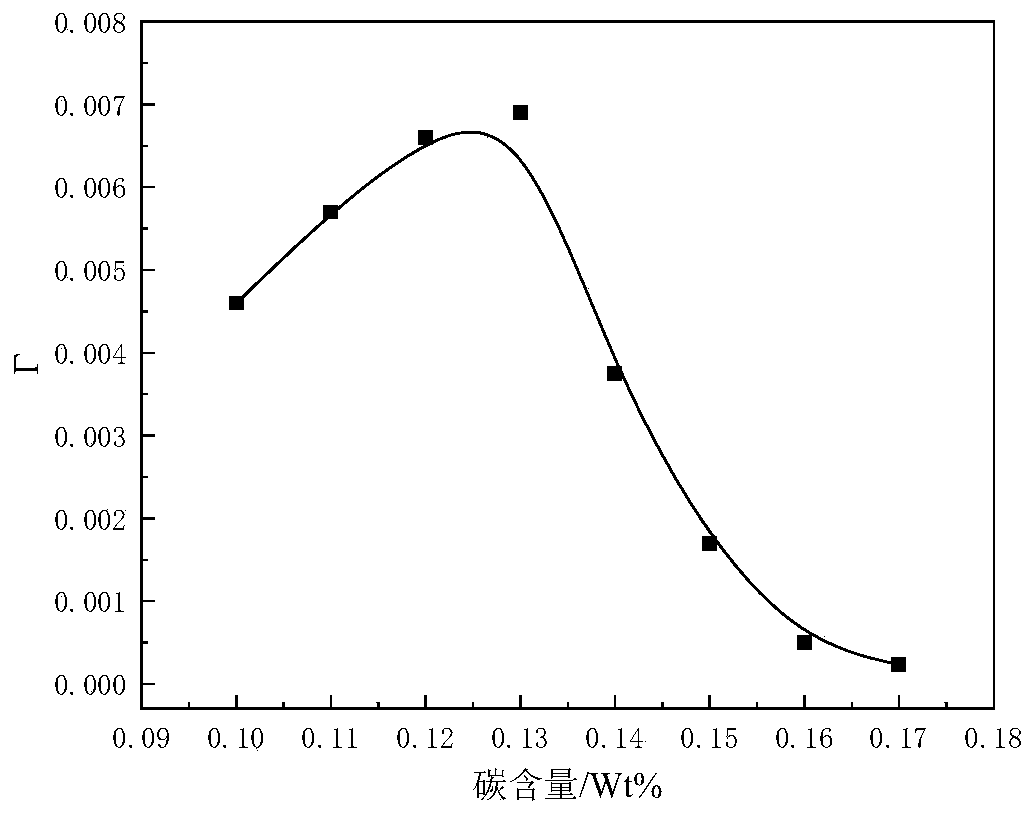

[0038] The chemical composition of the hypoperitectic ordinary carbon steel collected and produced is shown in Table 2. The relationship between the shrinkage rate (Γ) of the peritectic reaction body in the brittle temperature zone (LIT~ZDT) and the carbon content of molten steel is calculated and analyzed through the phase diagram. The calculation results are as follows figure 2 shown. according to figure 2 As a result, 0.15-0.17wt% of the carbon component whose shrinkage ratio Γ of the peritectic reaction body is less than 0.004 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com