Method for preventing longitudinal cracks on surface of sub-peritectic steel casting blank

A longitudinal crack and peritectic technology, applied in the field of continuous casting, can solve problems such as prone to longitudinal cracks, achieve the effects of reducing negative slip time, improving lubrication, and preventing longitudinal cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

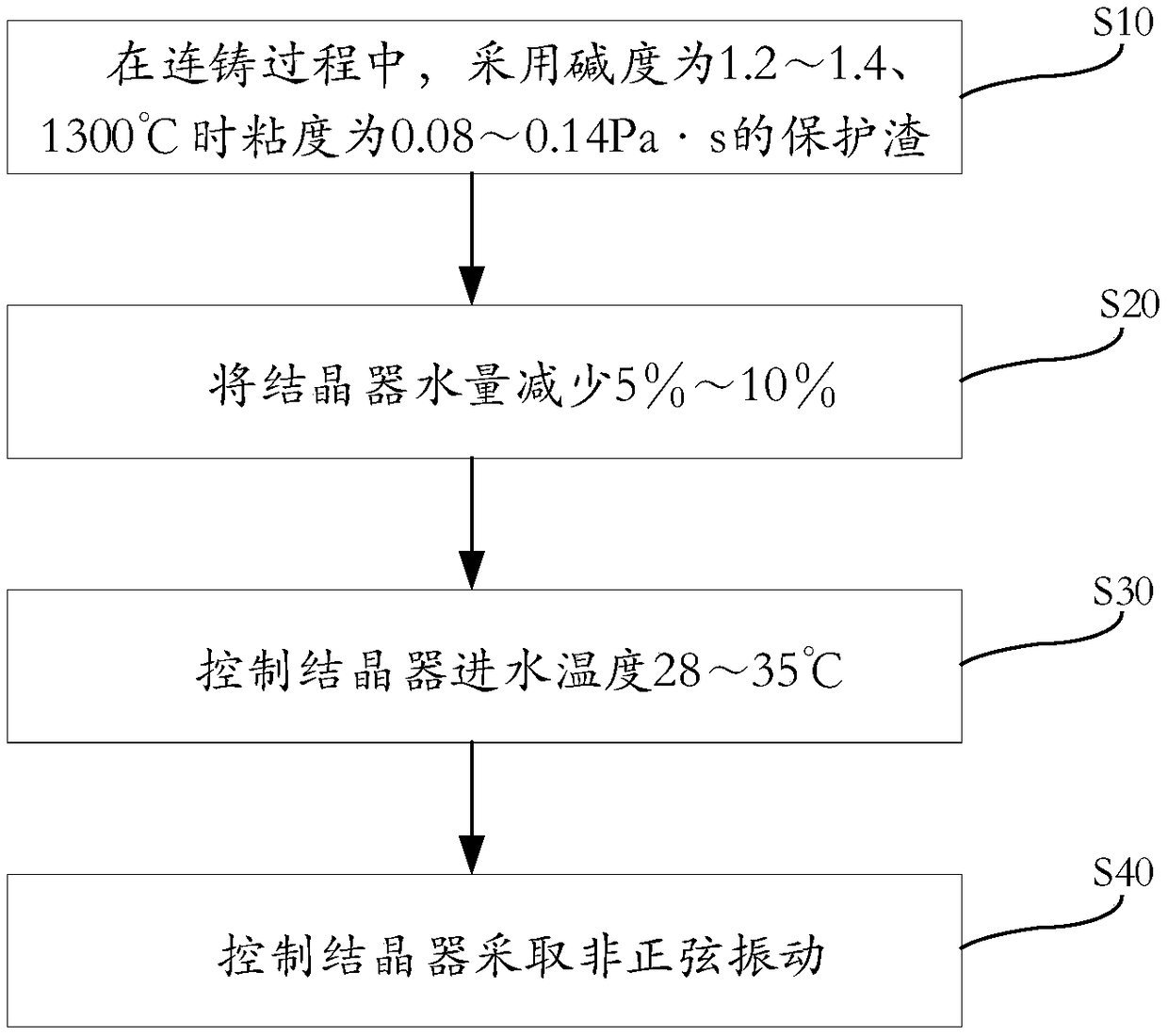

Method used

Image

Examples

Embodiment 1

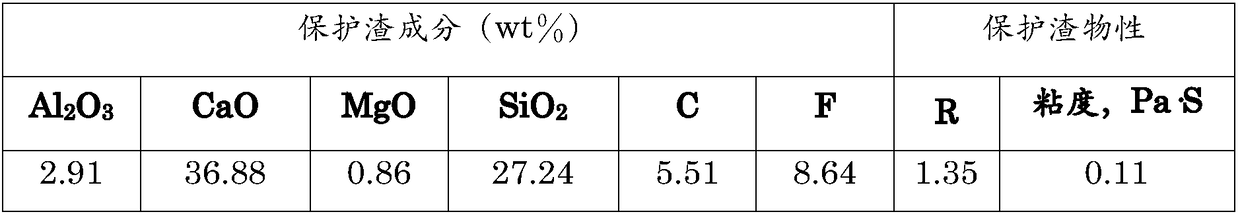

[0037] In this embodiment, the carbon content of the molten steel is C=0.101%, and the composition and physical properties of the mold flux used are shown in Table 1.

[0038]

[0039] Table 1

[0040] Among them, the billet casting speed is 1.3m / min; the billet specification is 230*1550mm; The flow velocity is 11m / s; the crystallizer inlet water temperature is 30.9°C. The crystallizer adopts non-sinusoidal vibration: the amplitude is 7.2mm, and the vibration frequency is 146min -1 , Negative slip time 0.105s.

[0041] No obvious longitudinal cracks were found on the surface of the slab produced by the continuous casting method of Example 1.

Embodiment 2

[0043] In this embodiment, the carbon content of the molten steel is C=0.127%, and the composition and physical properties of the mold flux used are shown in Table 2.

[0044]

[0045] Table 2

[0046] Among them, the billet casting speed is 1.2m / min, and the billet size is 230*1650mm; the water flow density at the wide side of the mold is 4400L / min, and the water flow rate is 8.2m / s; the water flow density at the narrow side of the mold is 460L / min, The water flow rate is 10.1m / s; the crystallizer inlet water temperature is 31.8°C. The crystallizer adopts non-sinusoidal vibration: the amplitude is 6.8mm, and the vibration frequency is 147min -1 , Negative slip time 0.105s.

[0047] No obvious longitudinal cracks were found on the surface of the slab produced by the continuous casting method of Example 2.

Embodiment 3

[0049] In this embodiment, the carbon content of the molten steel is C=0.089%, and the composition and physical properties of the mold flux used are shown in Table 3.

[0050]

[0051] table 3

[0052] Among them, the billet casting speed is 0.9m / min, and the billet specification is 230*1950mm; the water flow density of the wide side of the mold is 4400L / min, and the water flow rate is 8.2m / s; the water flow density of the narrow side of the mold is 460L / min, The water flow rate is 10.1m / s; the crystallizer inlet water temperature is 30.7°C. The crystallizer adopts non-sinusoidal vibration: the amplitude is 5.9mm, and the vibration frequency is 152min -1, the negative slip time is 0.104s.

[0053] No obvious longitudinal cracks were found on the surface of the slab produced by the continuous casting method of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com