Forklift truck type carrying trolley of flexible manufacturing system

A flexible manufacturing system, a technology for handling trolleys, applied in the directions of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of repeated positioning accuracy, poor accuracy retention, large dimensions of the pallet pick-and-place mechanism, and unsuitable for pick and place pallets. and other problems, to achieve the effect of low wear, improve the reliability of the machine tool, and high guiding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

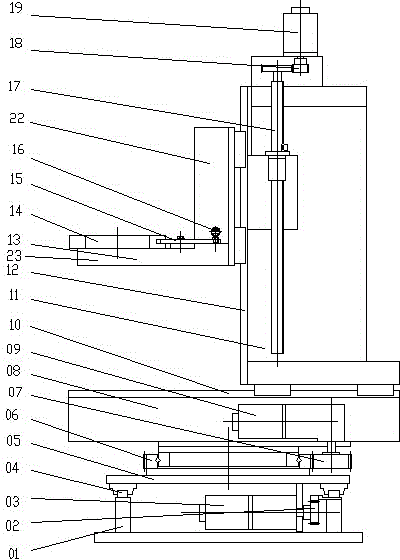

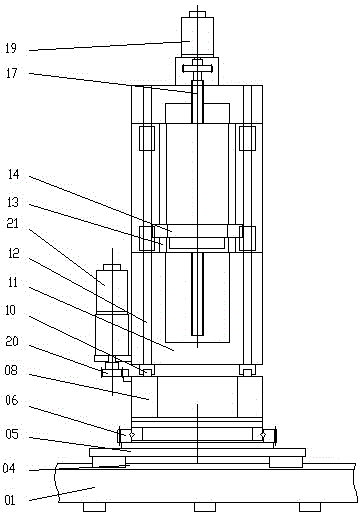

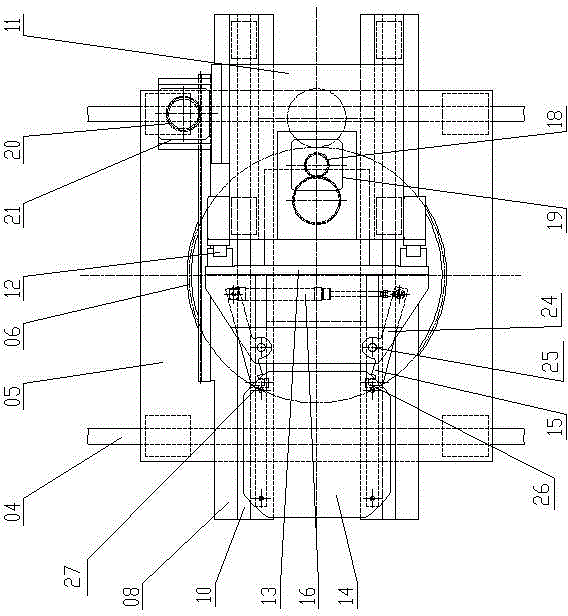

[0031] As a preferred embodiment of the present invention, the present invention discloses a forklift-type handling trolley for a flexible manufacturing system. The structure of the forklift-type handling trolley is quite different from that of the existing flexible manufacturing system. The main changes The point is: the X-direction linear guide rail 04 is installed on the X-direction guide rail bracket 01, the X-direction slide seat 05 is installed on the slider of the X-direction linear guide rail 04, and the X-direction drive gear 02 is installed under the X-direction slide seat 05. The X-direction driving gear 02 drives the X-direction slide seat 05 to move laterally on the X-direction rail bracket 01 through the rack and pinion. The rack and pinion transmission mode is relatively common, which makes the present invention simple in structure and reliable in operation.

Embodiment 2

[0033] As another preferred embodiment of the present invention, a B-direction toothed cross-roller bearing 06 is provided on the X-direction slide 05, and the B-direction slide 08 is mounted on the B-direction toothed cross-roller bearing 06 Above, a B-direction drive gear 07 is installed below the B-direction slide table 08, and the B-direction drive gear 07 drives the B-direction slide table 08 to rotate on the X-direction slide seat 05 through the gear. The gear transmission mode is relatively common, which makes the present invention simple in structure and reliable in operation.

Embodiment 3

[0035] As another preferred embodiment of the present invention, a Z-direction linear guide rail 10 is provided on the B-direction slide table 08, and the Z-direction column 11 is installed on the slider of the Z-direction linear guide rail 10. On the side of the Z-direction column 11, A Z-direction drive gear 20 is installed, and the Z-direction drive gear 20 drives the Z-direction column 11 to move longitudinally on the B-direction slide table 08 through the rack and pinion. All the other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com