Composite machining center with hot displacement constraint skid revolving joint portion macro/micro drive

A composite machining center, macro-micro drive technology, applied in the field of precision machine tools, can solve problems such as the influence of motion accuracy, the deterioration of the force condition of the mechanism, and the increase of working space, so as to achieve the effect of high processing efficiency and improved torque resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

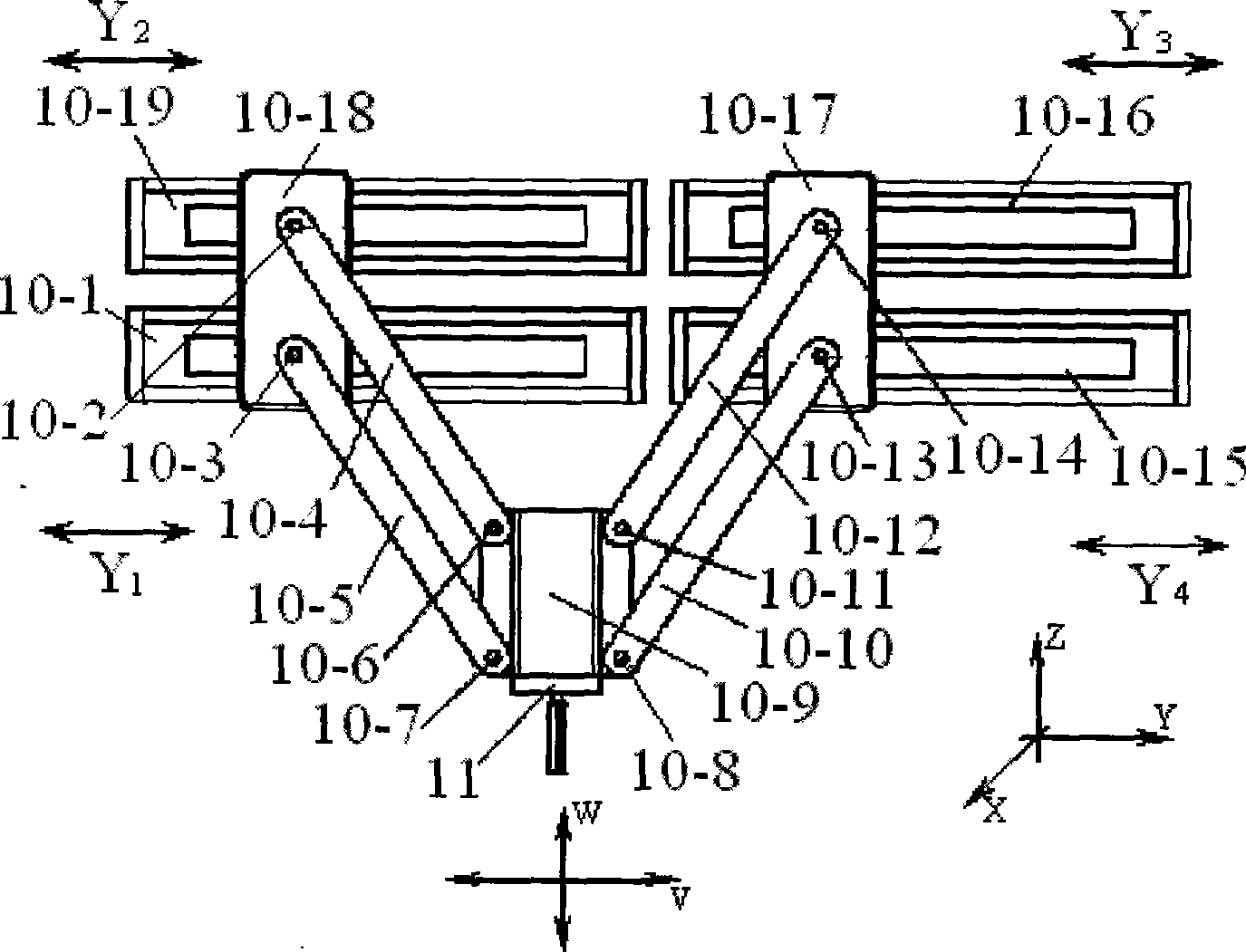

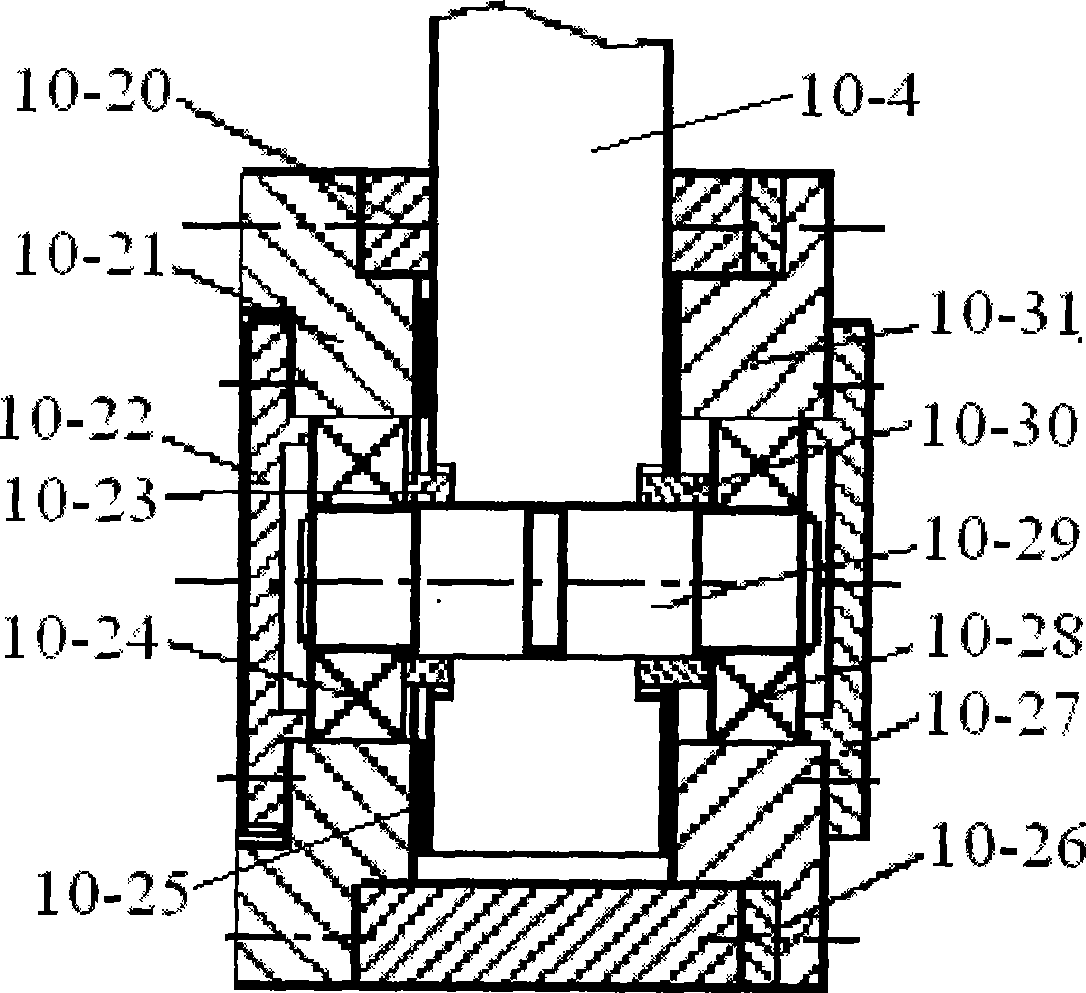

[0022] The main movement of the compound machining center of the present invention adopts a high-speed electric spindle with zero transmission; the milling feed function is realized by a hybrid principle mechanism that can realize high-speed feed; Zero-transmission linear motor and torque motor are realized; thermal displacement constraint joint mechanism is used between materials with different thermal characteristics; swing and rotary motion and the guidance of the rotary pair of parallel mechanism adopt rolling-slip rotary joint mechanism.

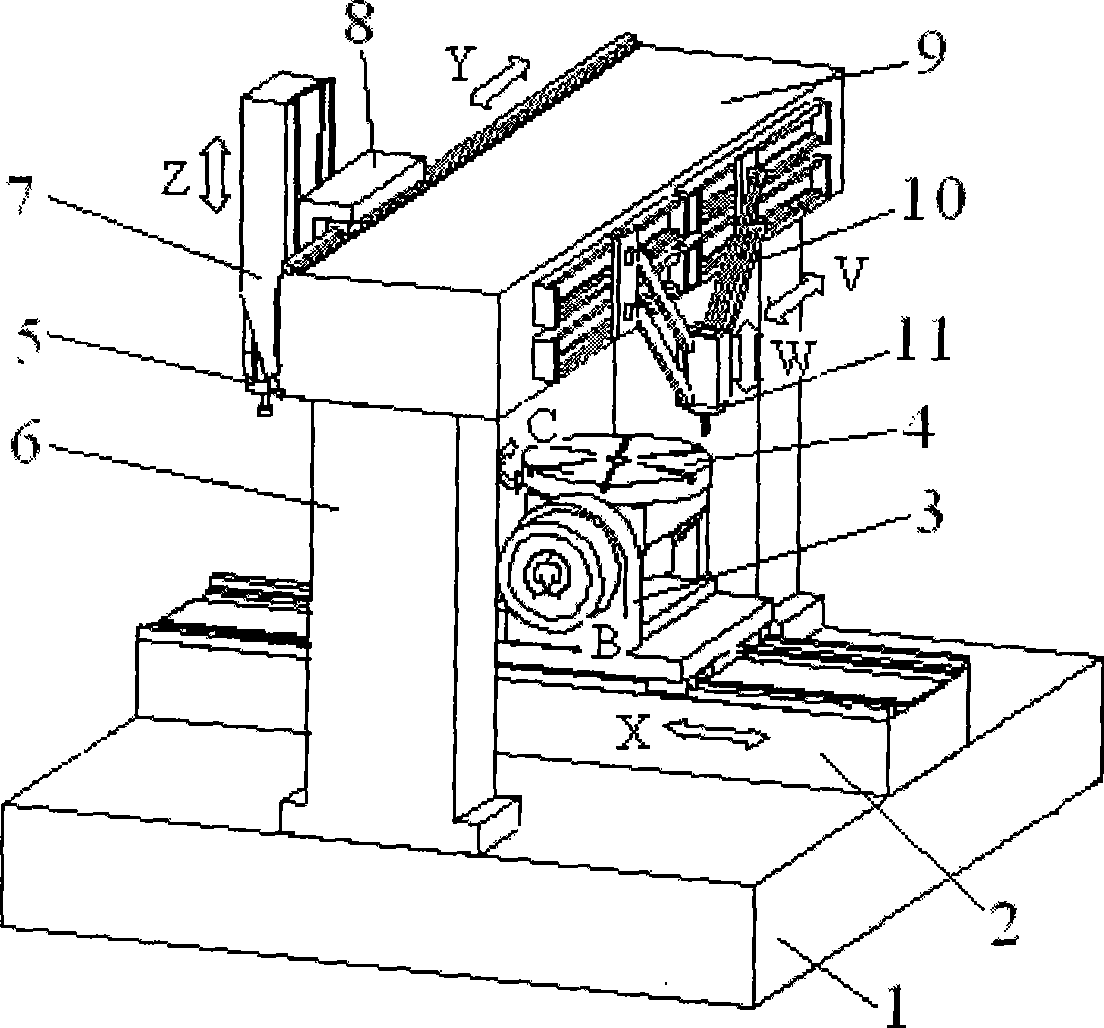

[0023] The structure of the compound machining center of the present invention, as figure 1 shown. Including the bed 1, the upper surface of the bed 1 is vertically arranged with two columns 6 side by side, the top surfaces of the two columns 6 are fixedly connected with a crossbeam 9, and the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com