Parallelism inspection tool for ball screw and guiding rail at gantry machining center

A machining center, ball screw technology, applied in the direction of angle/taper measurement, etc., can solve the problems of reading changes, affecting the reading accuracy, etc., to achieve the effect of convenient reading, improve measurement accuracy, and improve detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

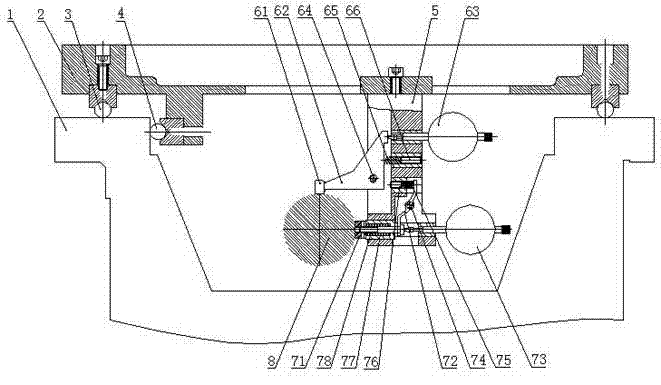

[0019] like figure 1 As shown, including guide rail 1, bridge plate 2, end limit 3, side limit 4, mounting plate 5, measuring block A61, toggle lever A62, dial indicator A63, positioning pin A64, return spring A65, measuring block B71 , Toggle lever B72, dial indicator B73, positioning pin B74 and return spring B75.

[0020] The above-mentioned bridge plate 2 is placed on the guide rail 1 , and a guide and limit assembly that can guide the bridge plate 2 along the extending direction of the guide rail 1 is arranged on it.

[0021] The guide limiter includes an end limiter 3 and a side limiter 4 installed on the lower end surface of the bridge plate 2. The end limiter 3 is against the upper end surface of the guide rail 1, and the side limiter 4 is against the inner wall of the guide rail. In this embodiment, the end limit 3 and the side limit 4 are cylindrical limit mandrels whose axes are parallel to the extending direction of the guide rail.

[0022] The middle part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com