Portable double-coil electromagnetic riveting device

An electromagnetic riveting and double-coil technology, which is applied in the field of mechanical processing, can solve the problems that the shock absorption system cannot quickly consume recoil energy, it is difficult to realize the problem of large-diameter rivet forming, and the energy of a single coil is limited, so as to improve energy utilization. Improves lifespan and reduces shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

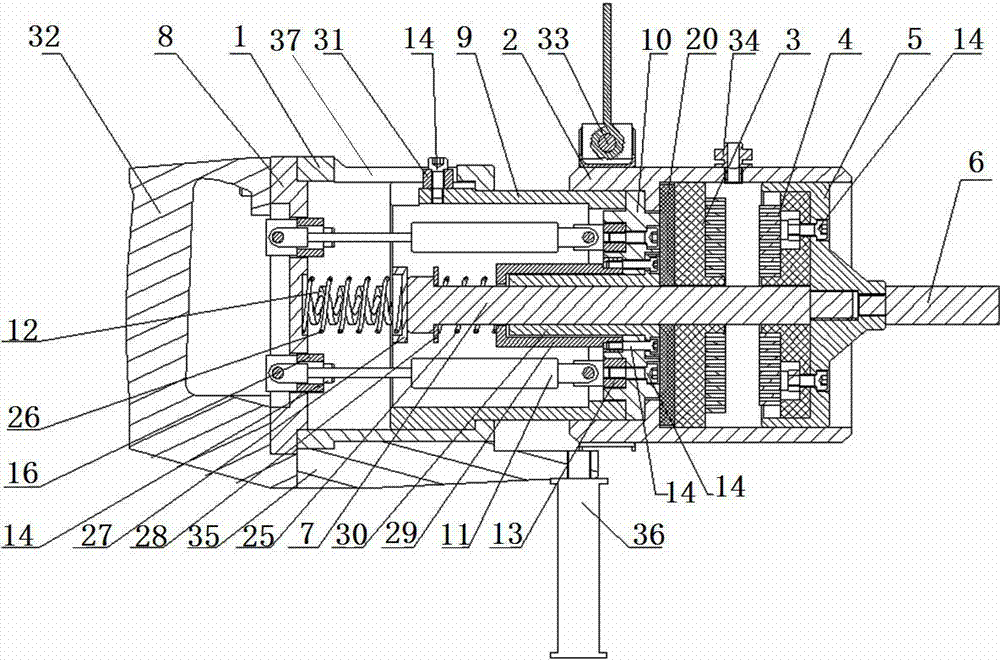

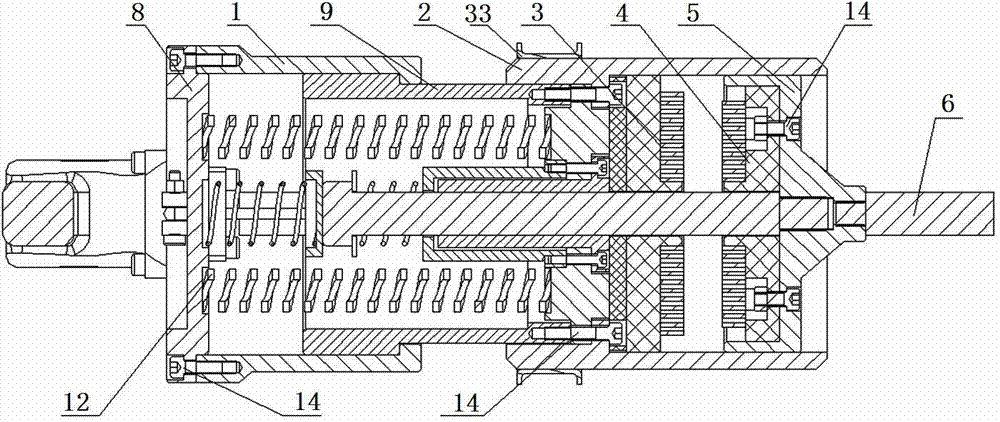

[0034] The present invention will be further described below with reference to the drawings and specific embodiments.

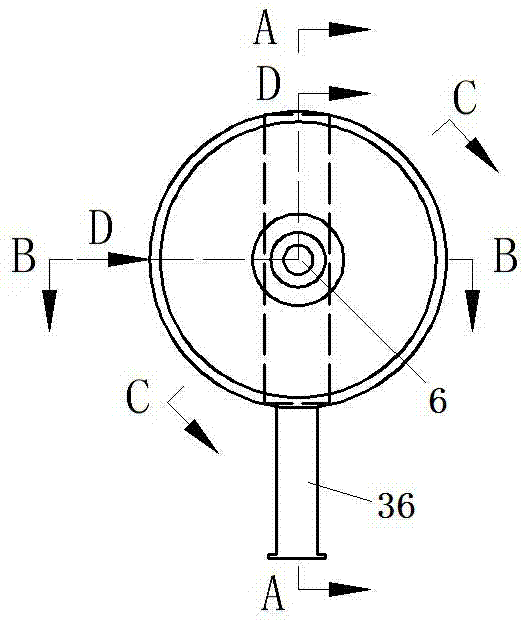

[0035] Such as Figure 1~13 As shown, a portable dual-coil electromagnetic riveting device includes a gun body rear barrel 1, a gun body front barrel 2, and the gun body front barrel 2 realizes relative reciprocating sliding movement with the gun body rear barrel 1 through a shock absorption system The front end of the gun body front barrel 2 is fixedly connected with a primary coil 3, and a slidable secondary coil 4 is sleeved beside the primary coil 3. The front end of the secondary coil 4 passes through an amplifier 5 and a riveting die. 6 is fixedly connected, the rear end surface is fixedly connected with an intermediate shaft core 7 passing through the primary coil 3. The intermediate shaft core 7 is opposite to the gun body rear barrel 1 and the gun body front barrel 2 through an elastic limit mechanism and a guiding mechanism With reciprocating sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com