Supporting article for preventing sand from subsiding

A technology for support and sand control, applied in sheet pile walls, excavation, construction, etc., can solve the problems of insufficient strength and rigidity, time-consuming, and can not expect the quality of the sand control collapse wall, etc., to shorten the construction time, improve the construction accuracy, inject volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

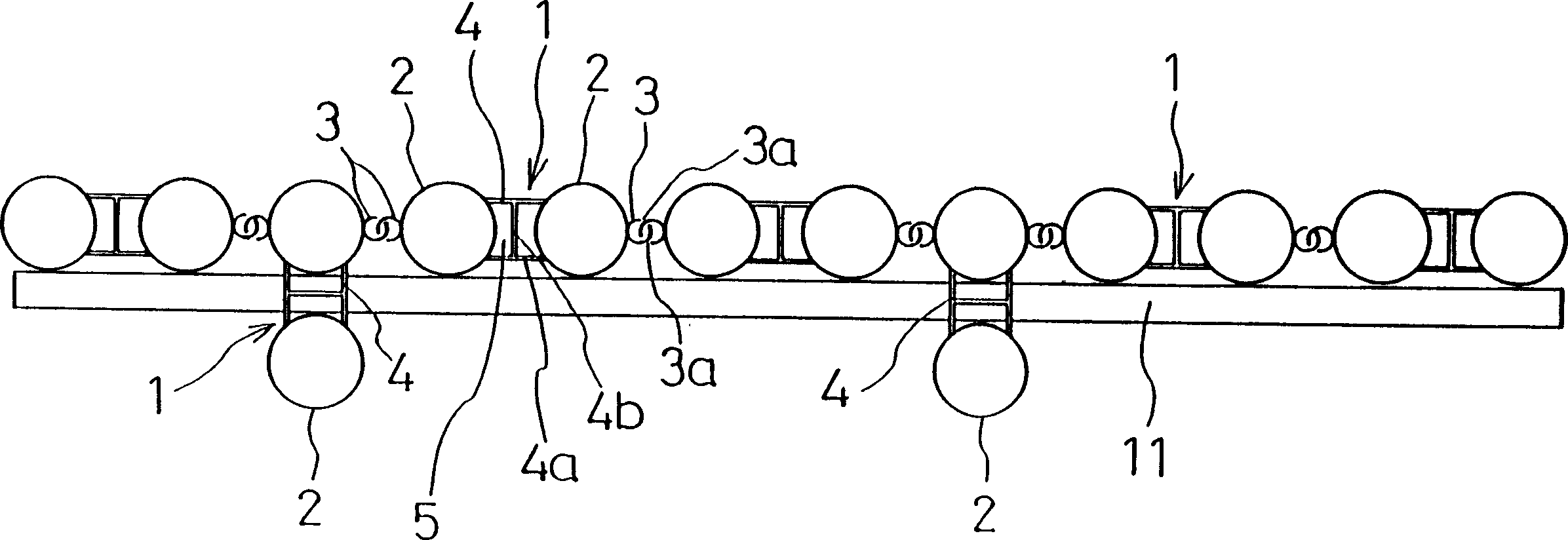

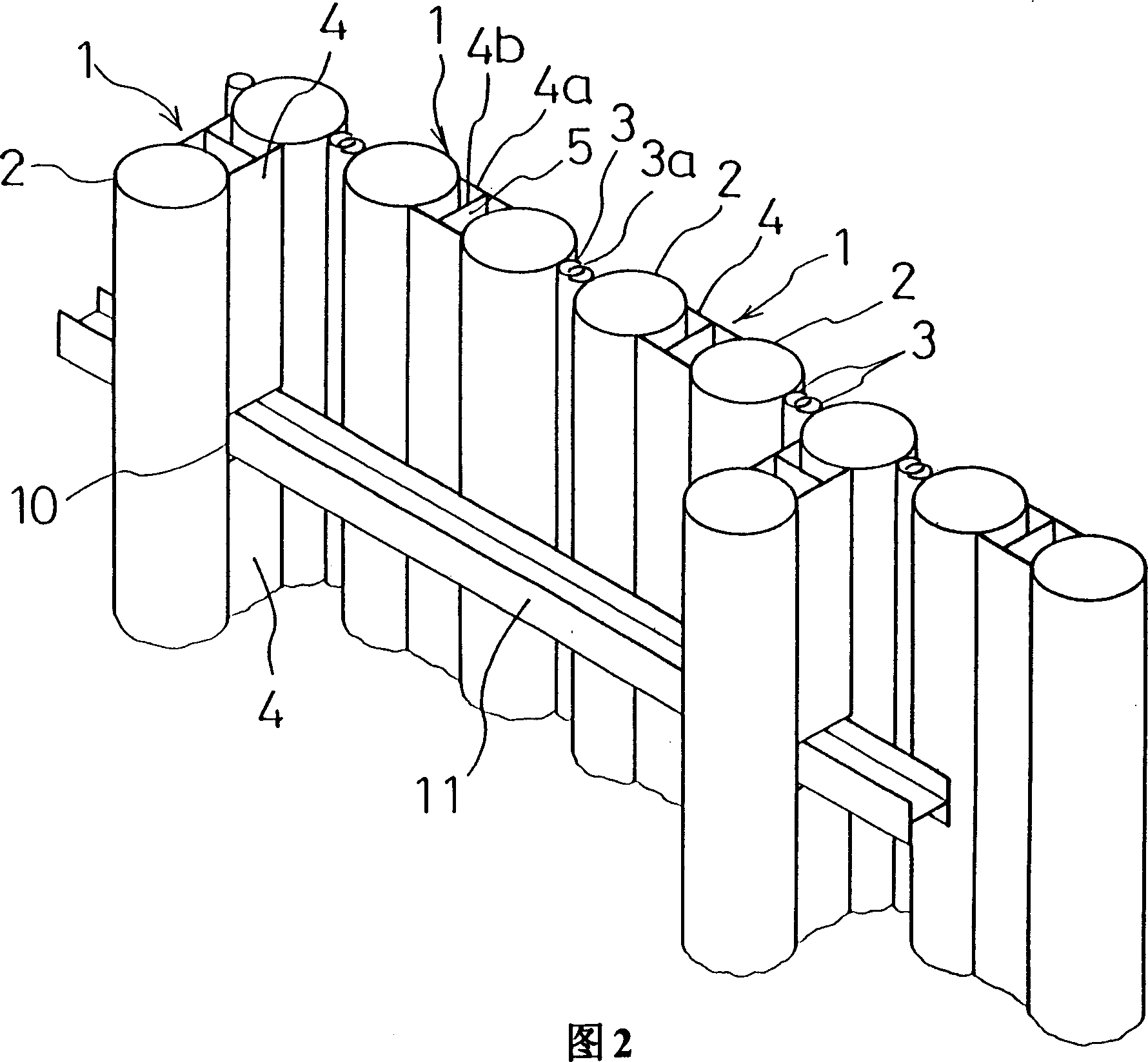

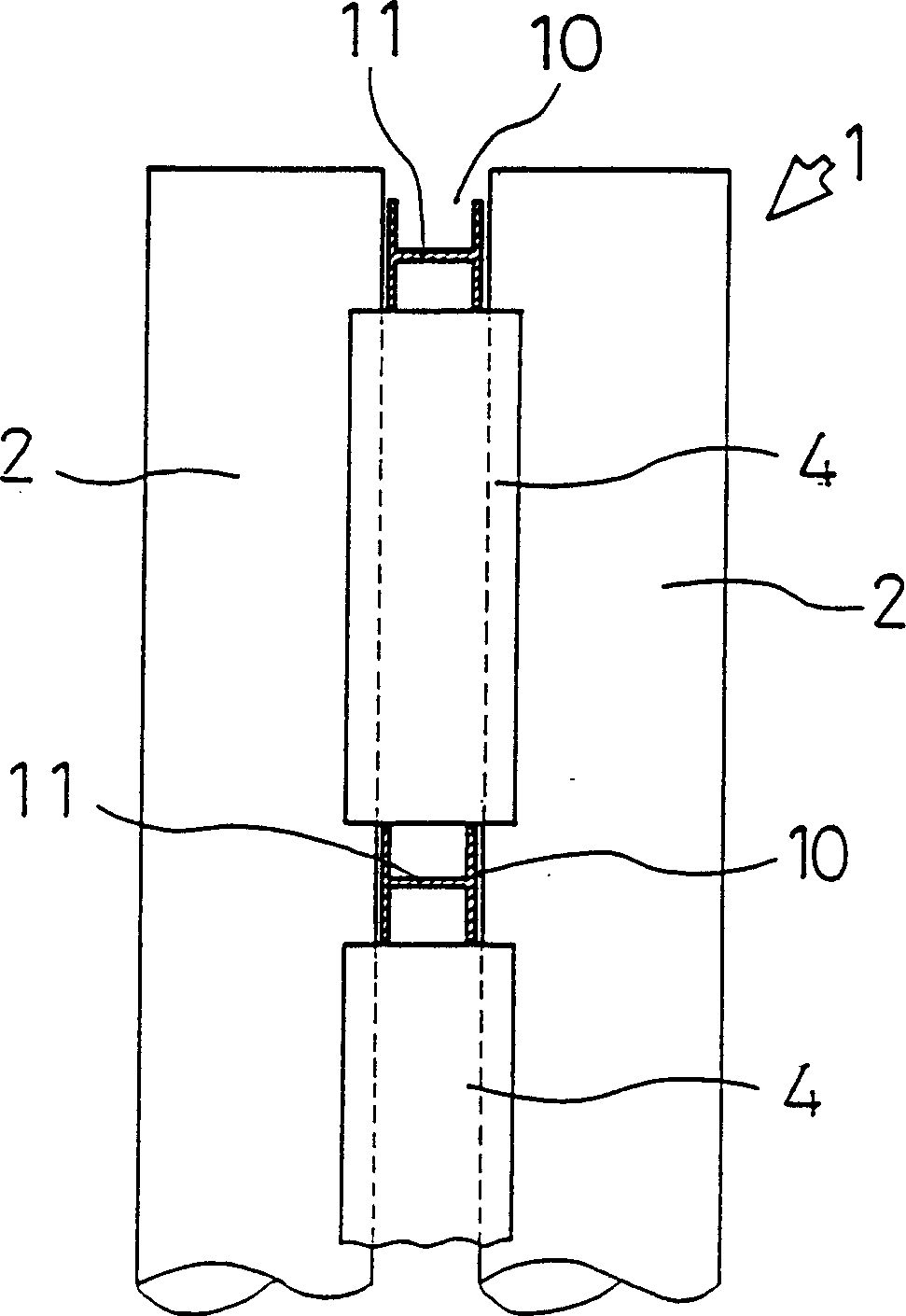

[0039] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 A plan view showing the first embodiment of the sand collapse prevention support of the present invention, FIG. 2 is the same perspective view as above, and the steel pipe sheet pile 1 as the support unit used in the present invention is also the same as the aforementioned Japanese Patent Application No. 2001-198112, Each parallel steel pipe 2 is integrally connected with the parallel steel pipes 2 with the H steel 4 as an H-shaped tie bar member whose edge is combined with the peripheral surface of each steel pipe 2, and the width direction of the H steel 4 is There is a gap, and in addition, a joint 3 is provided on the side opposite to the above-mentioned interconnection.

[0040] The H-steel 4 is made of section steel, and may be separately assembled by appropriate welding in a factory or the like. In the case of using shaped steel, the left and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com