Laser level gauge and application of laser level gauge in installation of bridge stand

A laser level, laser level technology, applied in instruments, measuring devices, measuring instruments and other directions, can solve the problems of low efficiency, low precision, inconvenient use, etc., to save installation and construction time, improve work efficiency, and reduce engineering costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

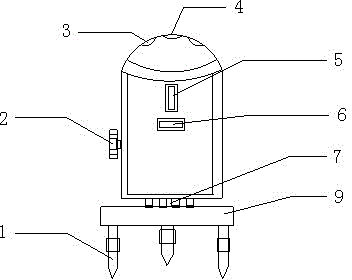

[0029] see now figure 1 , figure 1 It is a schematic structural diagram of a laser level in an embodiment of the present invention. As shown in the figure, the base is a disc, and the bottom of the disc is provided with three telescopic legs 1 for adjusting the levelness and height of the laser level;

[0030] The upper part of the cylinder body is provided with a dome cover, a level 4 is provided at the top of the dome cover, and a fine-tuning button 3 is provided in the middle of the dome cover; four laser emitters 15 are arranged in the cylinder body, and the four laser emitters are arranged on the same plane. Arranged in a cross shape with each other, each laser emitter is provided with a laser vertical line emission window and a laser horizontal line emission window on the corresponding cylinder circumference, and the fine-tuning button 3 is connected with the electronic system built in the emitter to adjust the output of the laser emitter. The direction and angle of th...

Embodiment 2

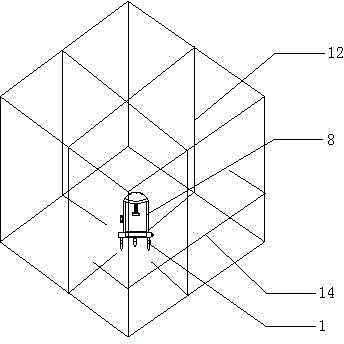

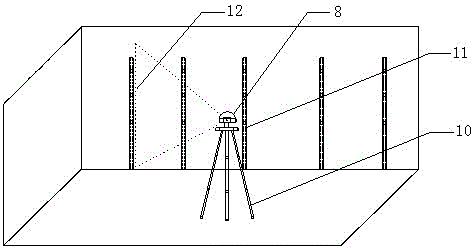

[0035] see now image 3 and Figure 4 , image 3 It is a schematic diagram of using a laser level to control the installation of bridge columns in an embodiment of the present invention, Figure 4 It is a schematic diagram of using a laser level to control the installation of a bridge support arm according to an embodiment of the present invention.

[0036] The method of using the laser level of the present invention in the installation of the bridge support arm is as follows:

[0037] 1. Place the laser level on a tripod, or on a stable plane, and place it next to the bridge to be installed, and adjust the three legs on the base to make the instrument bubble in the line.

[0038] 2. When the circular level bubble is centered and the laser level is leveled, turn the switch knob clockwise to turn on the instrument. At the same time, the transmitters on the four sides emit laser beams. The laser beams on each side are composed of vertical and horizontal linear laser beams. V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com