Detachable follow-up frame and installation process thereof

A follower frame, disassembly-type technology, applied in the field of follower frame, can solve the problems of increased assembly risk and assembly cost, inability to complete the vertical pole, equipment tilting forward and overturning, etc., to solve the inconvenience of installing the follower frame , Saving drilling cost, avoiding the effect of partial holes and waste holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

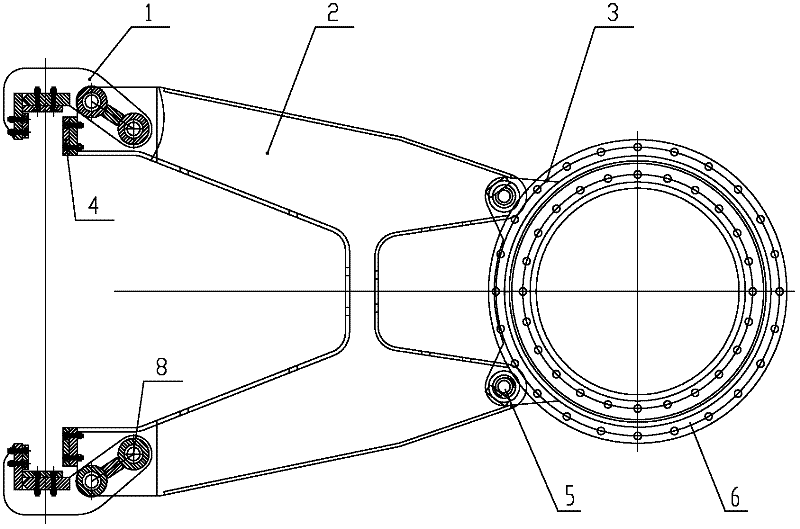

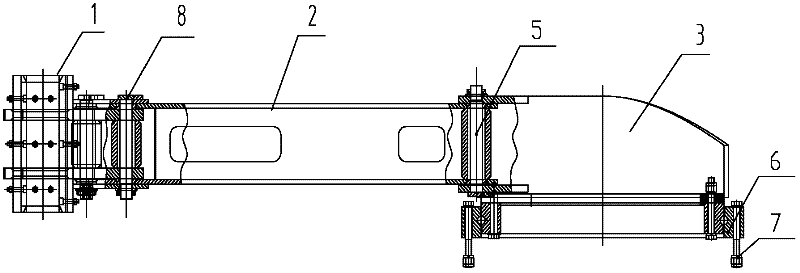

[0023] see figure 1 and figure 2 , the inner ring of the support plate 3 and the slewing support 6 is connected by bolts, the outer ring of the slewing support 6 is connected with the drill pipe assembly 14 by bolts 7, one end of the support frame 2 is connected with the support plate 3 by the first pin shaft 5, and the support frame 2 The other end is connected with the sliding lug 1 by the second pin shaft 8, and the two sliding lugs 1 are equipped with a nylon sliding plate 4.

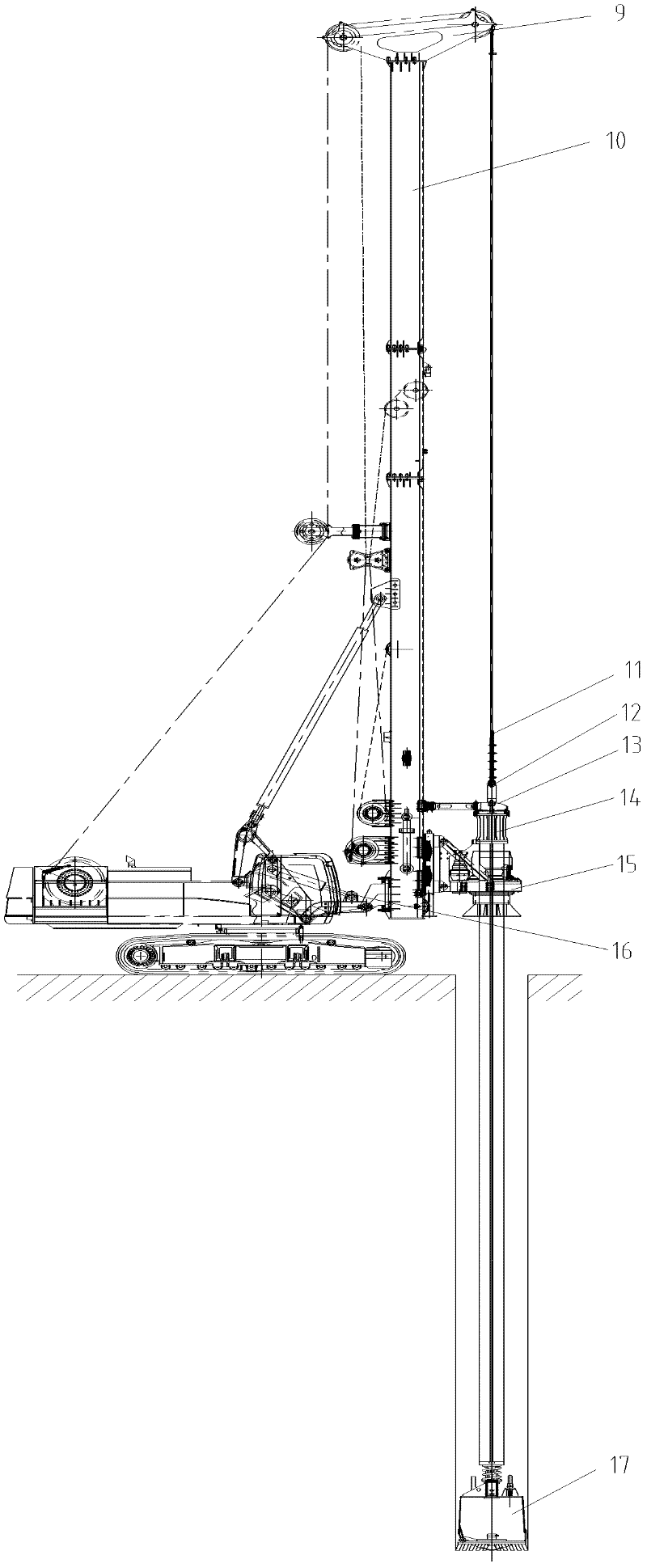

[0024] see figure 1 , figure 2 and image 3 , the installation process of the detachable follower frame, including a detachable follower frame 13, a drill pipe assembly 14, a drill bucket 17, a lifter 12, a main winch wire rope 11, a hoist Anchor frame 9, a mast assembly 10, power head assembly 15 and a luffing assembly 16, comprise following four steps:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com