Low-dose injection drug production line fil anti-dripping device

An anti-drip device and production line technology, applied in the direction of packaging, transportation and packaging, and the type of packaged items, can solve the problems of dripping on the outer wall of the current or next small-dose medicine bottle, dripping of medicine liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

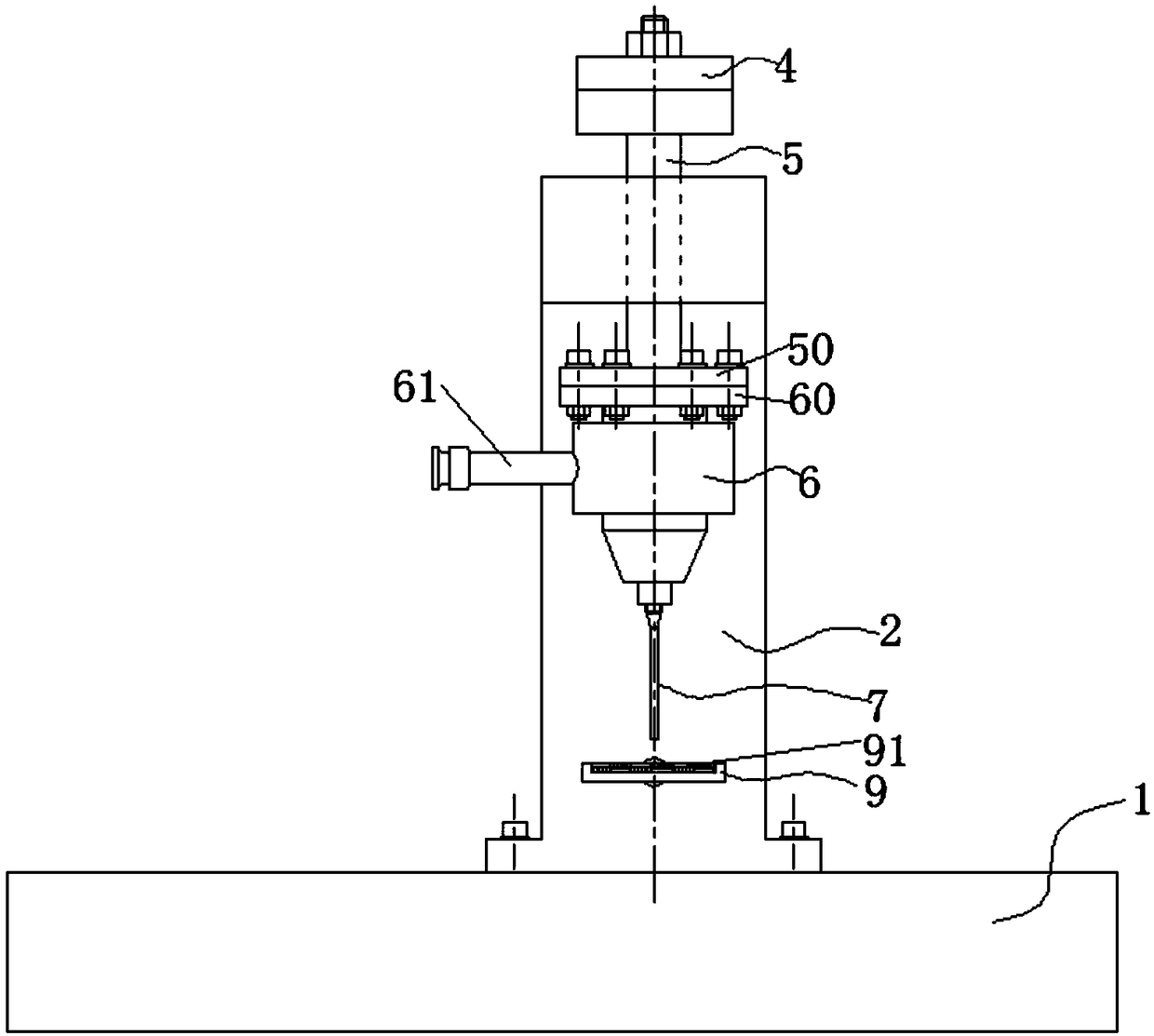

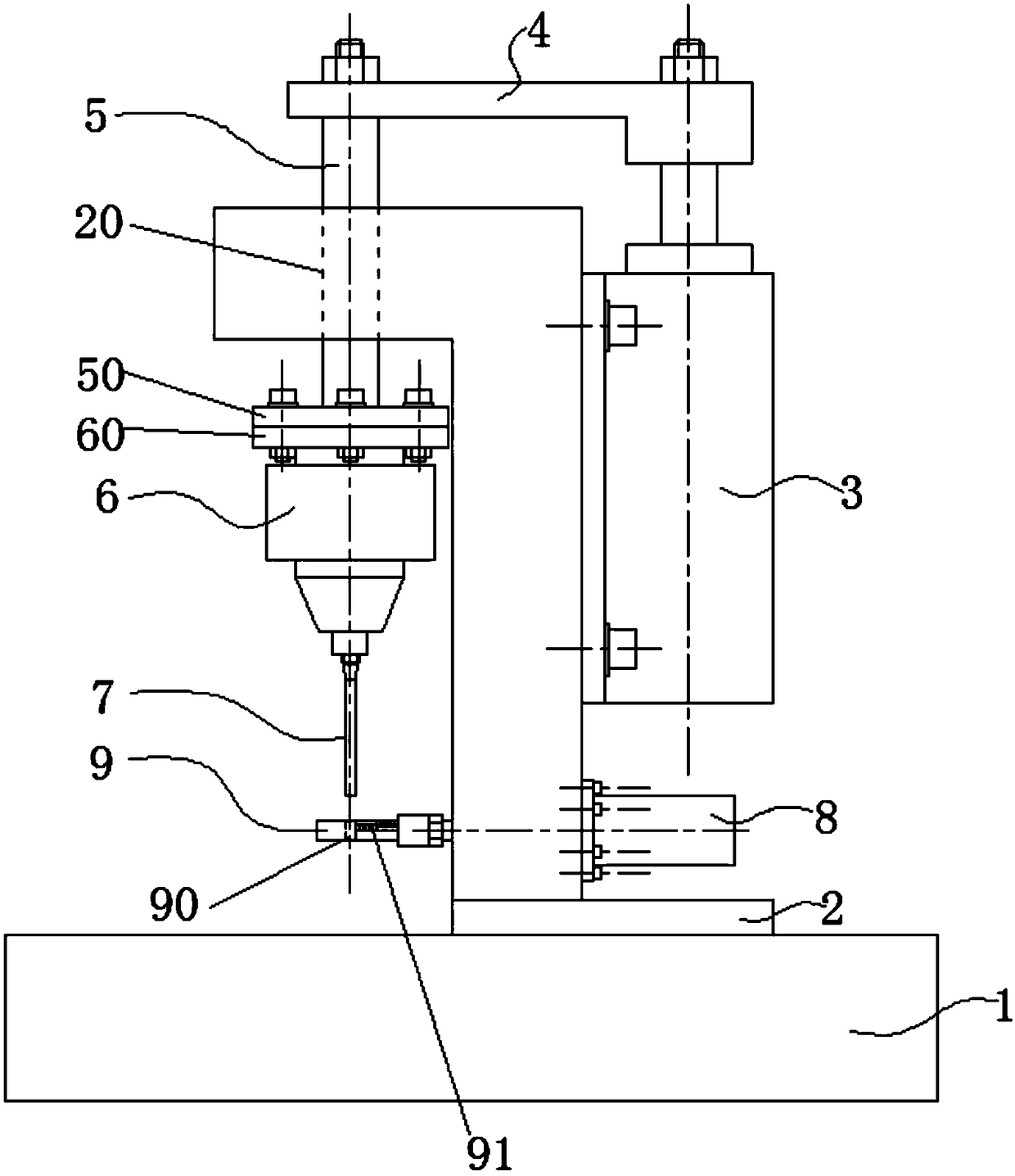

[0025] The filling anti-drip device of the small-dose injection drug production line, when filling, first start the cylinder one 3, the piston rod of the cylinder one 3 shrinks, and then the cylinder one 3 moves down with the filling rod 5 through the pressing plate 4, and the filling rod 5. The filling head 6 at the lower end and the filling needle 7 connected to the filling head 6 move downwards, and the filling needle 7 passes through the cylindrical hole 90 on the liquid receiving plate 9, so that the filling needle 7 extends into the small-dose medicine bottle Carry out the filling operation. After the filling is completed, the piston rod of the cylinder one 3 is extended, and then the cylinder one 3 moves upward with the filling rod 5 through the pressure plate 4, and the filling head 6 at the lower end of the filling rod 5 and the filling The filling needle 7 connected to the head 6 moves upwards, so that the filling needle 7 protrudes from the small-dose medicine bottle...

Embodiment 2

[0027] The support 2 is a "Z" structure, which facilitates the installation of the cylinder one 3 and the filling head 6; the support 2 is provided with a guide hole 20, so that the filling rod 5 moves up and down stably; the filling rod 5 The lower end is provided with a flange 1 50, and the upper end of the filling head 6 is provided with a flange 2 60, and the flange 2 60 and the flange 1 50 are connected by bolts to ensure that the filling needle 7 is installed on the filling head 6, The vertical precision is high; the side of the filling head 6 is provided with a liquid inlet 61 to facilitate the connection of the rubber hose of the filling device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com