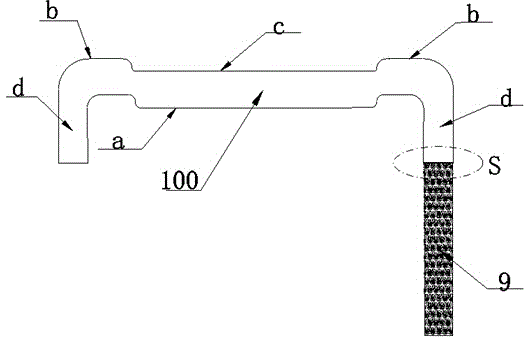

Die frame

A frame and mold technology, applied in the field preparation and construction of formwork/template components, building components, etc., can solve the problems of low precision, inaccurate verticality, insufficient pressure resistance, etc., to improve the compressive strength and Bearing capacity, high vertical accuracy, error avoidance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the drawings.

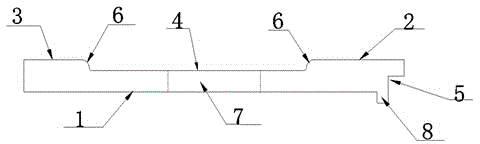

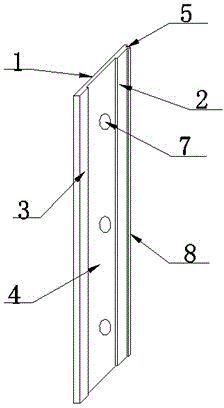

[0014] This embodiment provides a mold frame, such as figure 2 with 3 As shown, the frame is composed of a bottom edge 1, a large flat side 2, a small flat side 3, an elastic side 4, two compression angles 6 and a notch 5 formed by an integrated hot rolling forming process, a large flat side 2 and Between the small flat side 3 is the elastic side 4, the large flat side 2, the small flat side 3 and the elastic side 4 are all parallel to the bottom side 1. An arc-shaped compression resistance is provided at the junction of the large flat side 2 and the elastic side 4 Angle 6, at the junction of the small flat side 3 and the elastic side 4 is also provided with the same pressure-resistant angle 6, between the elastic side 4 and the bottom side 1, there is a row of pin holes 7, at the end of the frame, the large flat side A splicing right-angle notch 5 is opened between 2 and bottom si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com