Lateral punching die for cylindrical parts

A technology of lateral punching and cylindrical parts, applied in the field of punching dies, which can solve problems such as increased production costs, use and maintenance costs, difficulty in ensuring the phase of multiple holes, and large structural dimensions of punching dies, etc., to reduce production costs As well as the use and maintenance costs, the convenience of material guidance, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

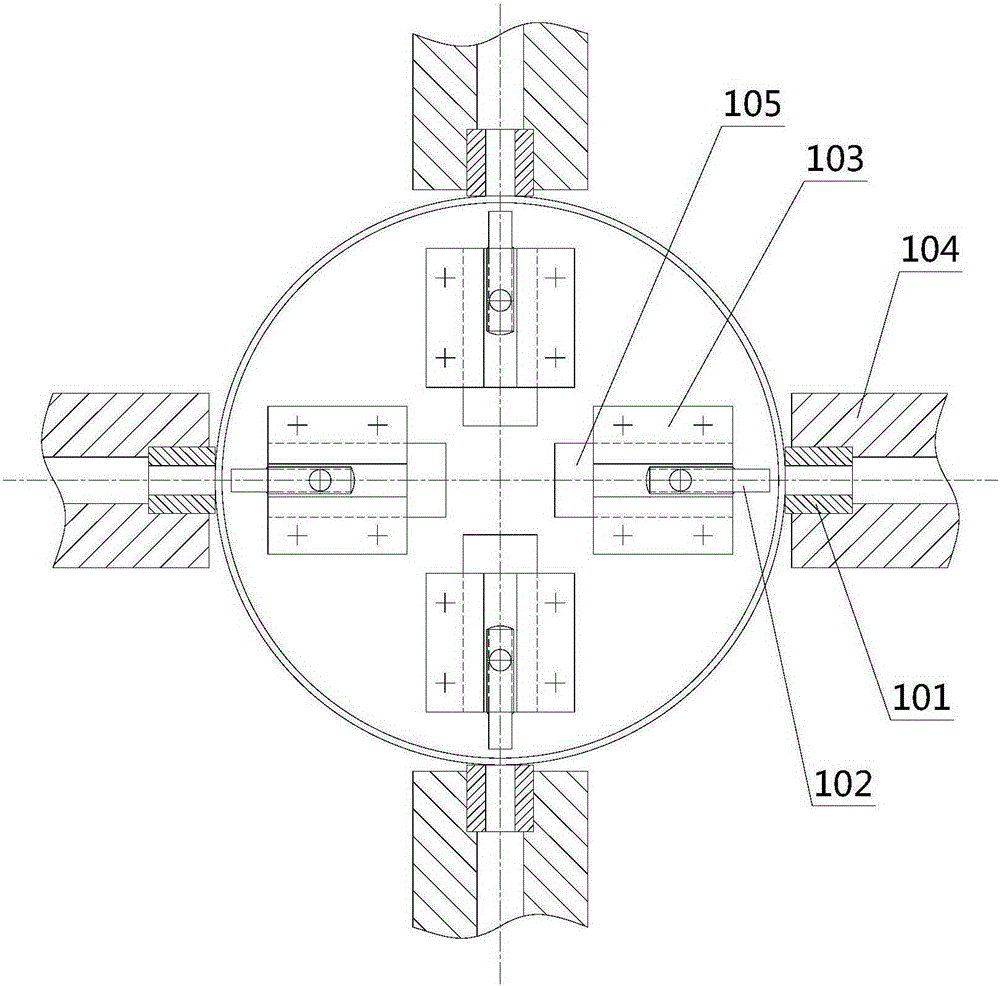

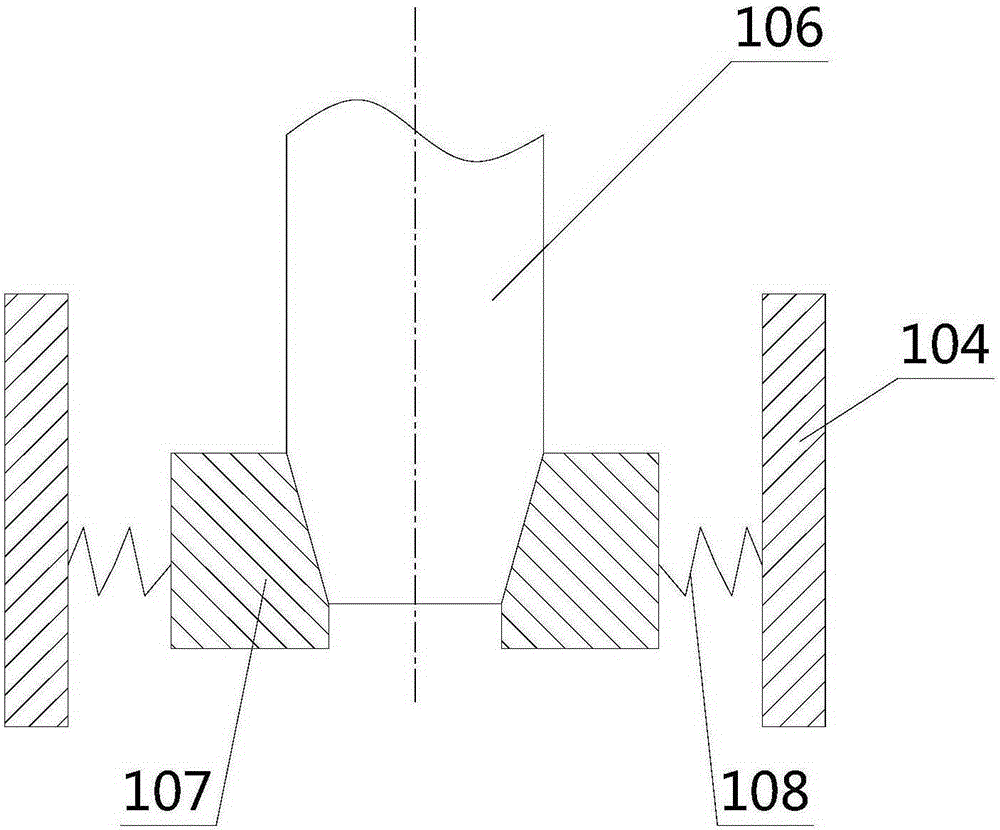

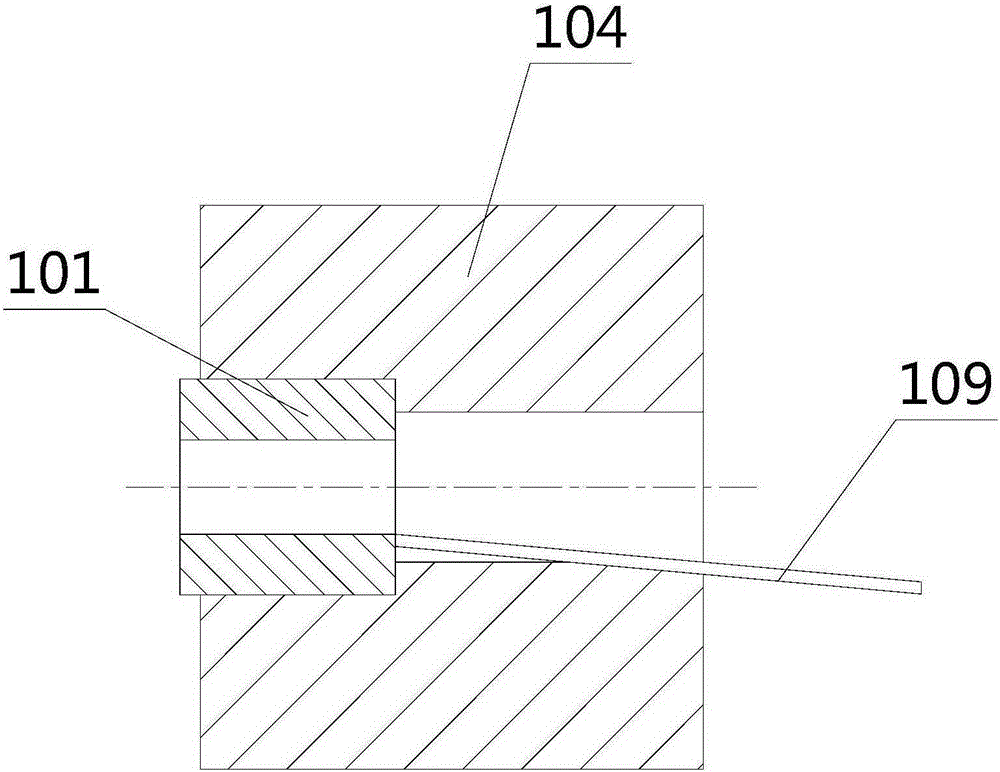

[0036] This embodiment provides a side punching die for a cylindrical part, which is used for punching the side wall of a large-diameter cylindrical part. see figure 1 , the lateral punching die of the cylindrical member includes a plurality of punching units, the punching unit includes a die 101 and a punch 102 that can cooperate with each other, the punch 102 is fixed on the slider 103, and the die 101 is fixed on the base 104, the slider 103 is slidably connected with the slide rail 105.

[0037] The lateral punching die for cylindrical parts provided in this embodiment realizes punching by sliding the slider 103 on the slide rail 105, and multiple punching units can punch holes at the same time, and a single clamping can process multiple holes , improve punching accuracy, no need for multiple clamping, save man-hours, especially suitable for punching large-diameter cylindrical parts, and reduce mold manufacturing costs, use and maintenance costs.

[0038] On the basis of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com