Roll forming processing method for online punching and production line

A technology of roll forming and processing method, which is applied in the field of sheet metal roll forming processing, can solve the problems of frequent braking, slow speed, high energy consumption, etc., and achieve the effect of improving punching accuracy and processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific embodiment

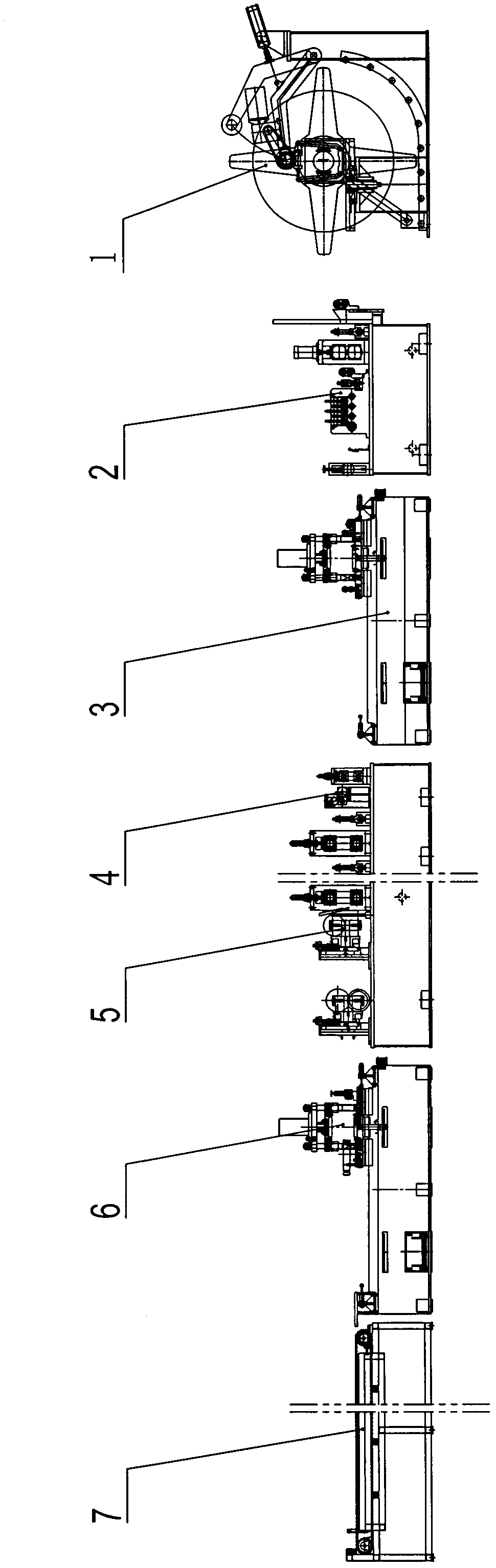

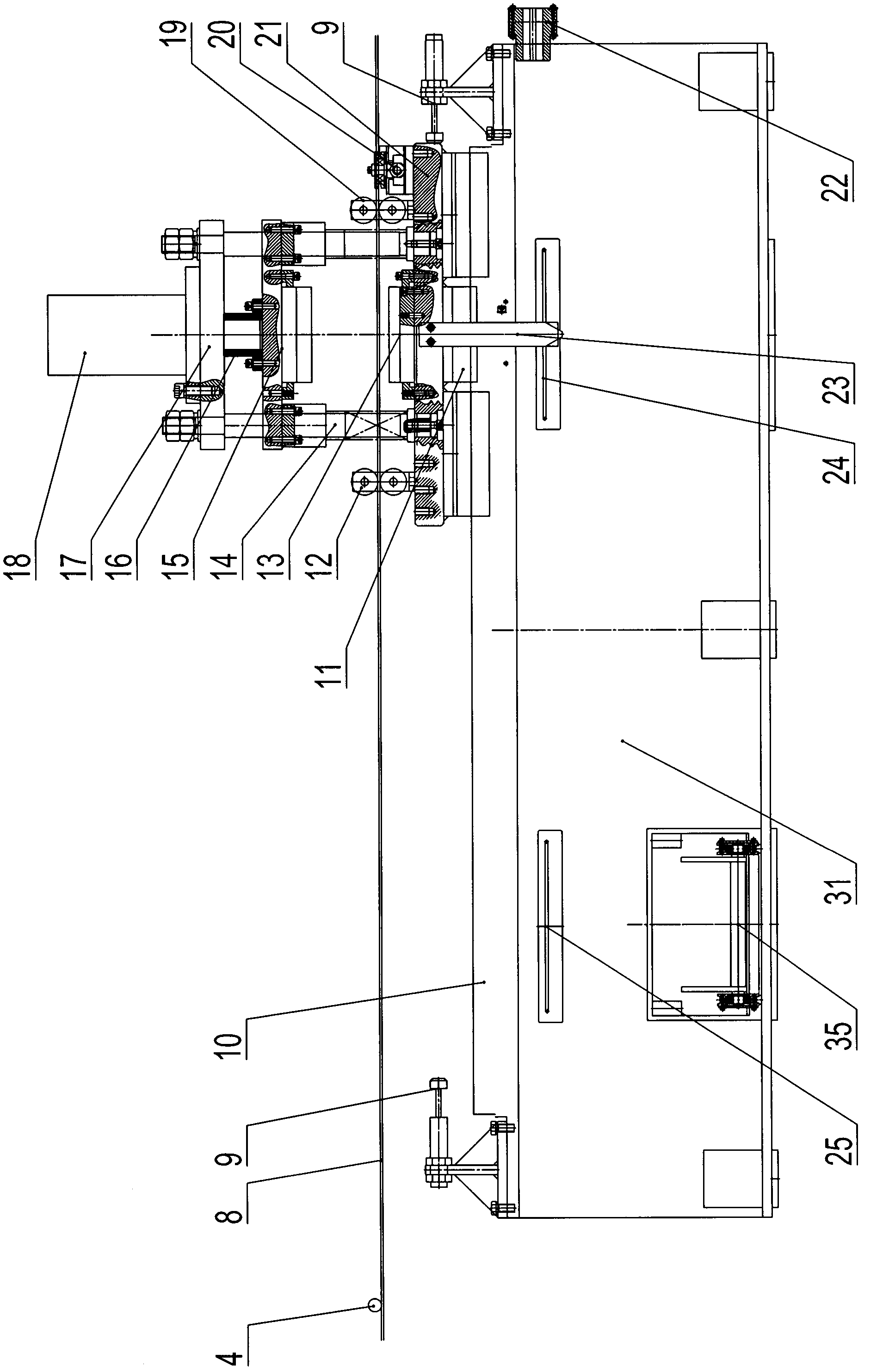

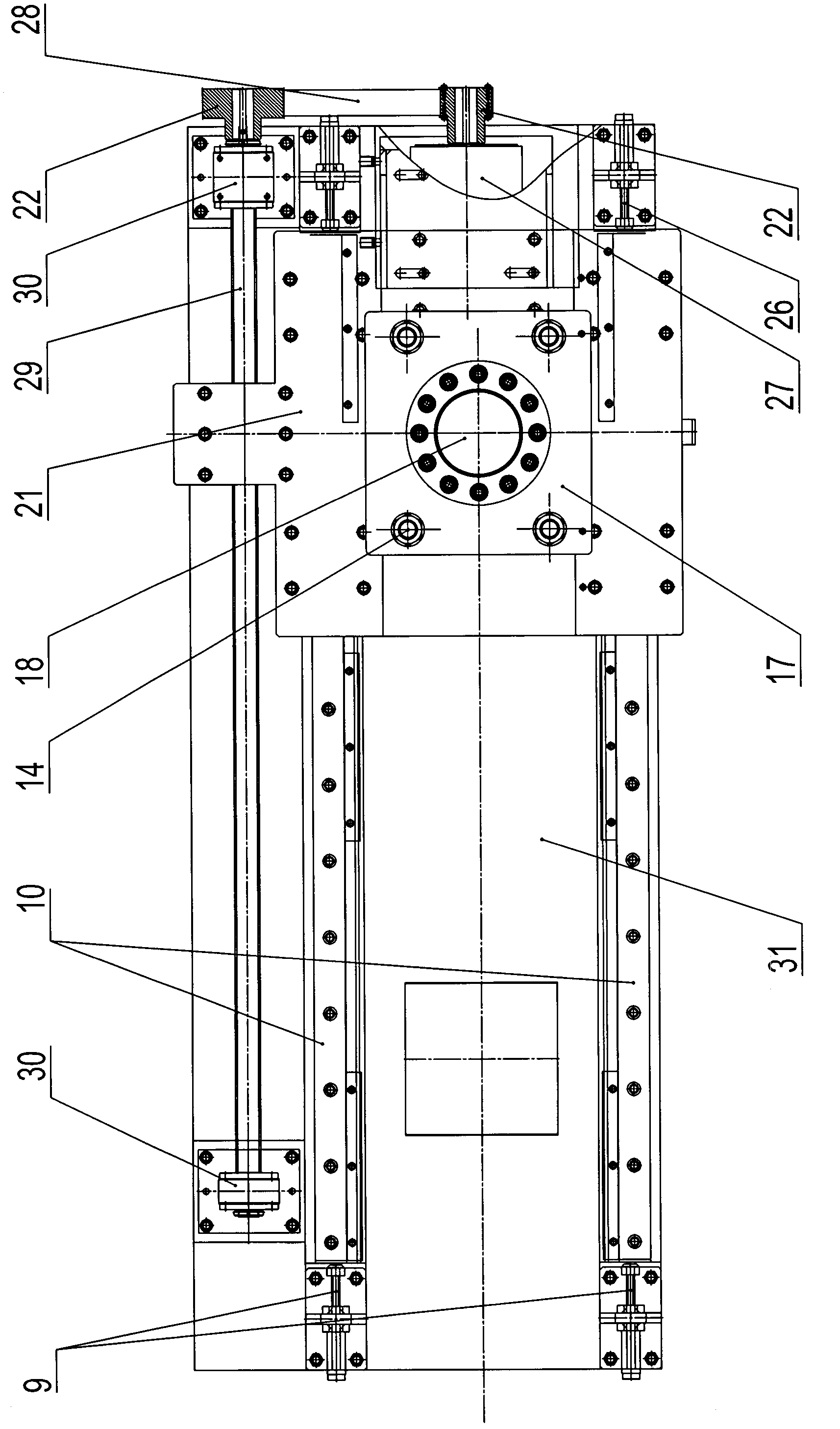

[0026] The roll forming processing method of online punching includes the steps of discharging, leveling, punching, roll forming, cutting and blanking in sequence. Among the above steps, the steps of discharging, leveling, roll forming, cutting and blanking All can be the same as the working method of sheet metal roll forming in the prior art, the difference is the punching step, and the punching step is composed of the following sub-steps in turn:

[0027] 1) Detect the real-time displacement signal of the linear motion of the sheet metal;

[0028] 2) According to the real-time displacement signal, the punching mechanism is driven to accelerate and move along the movement direction of the sheet to catch up with the sheet until it reaches the set punching position;

[0029] 3) Drive the punching mechanism to track the linear motion of the coiled plate and keep it moving sync...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com