Plate punching die and punching method thereof

A plate and punching technology, applied in the field of stamping die, can solve the problems of complicated die replacement, poor punching accuracy, low punching efficiency, etc., and achieve the effects of easy replacement, less time and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

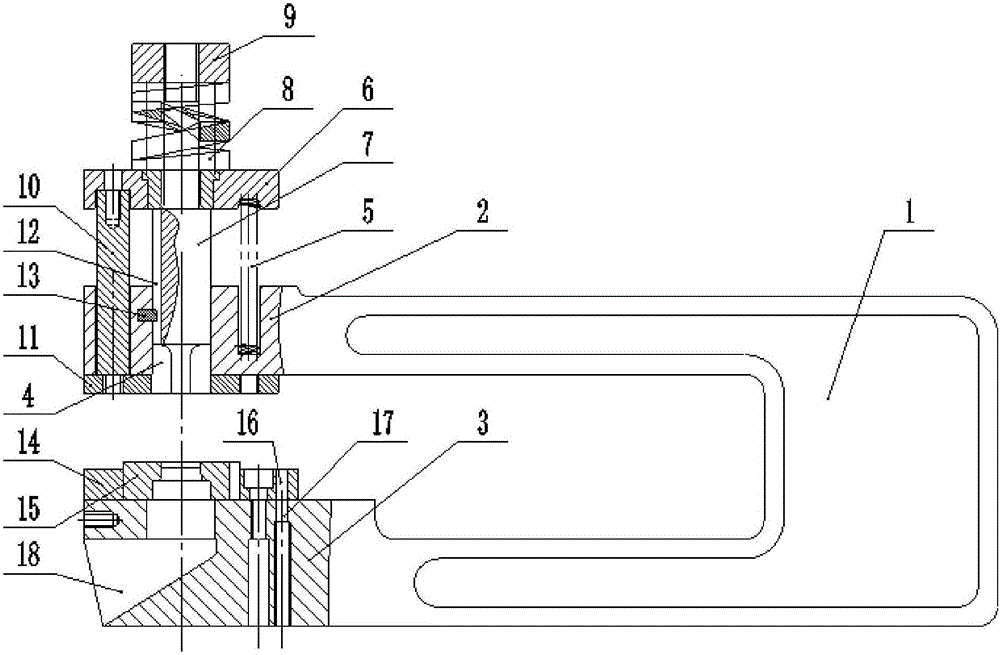

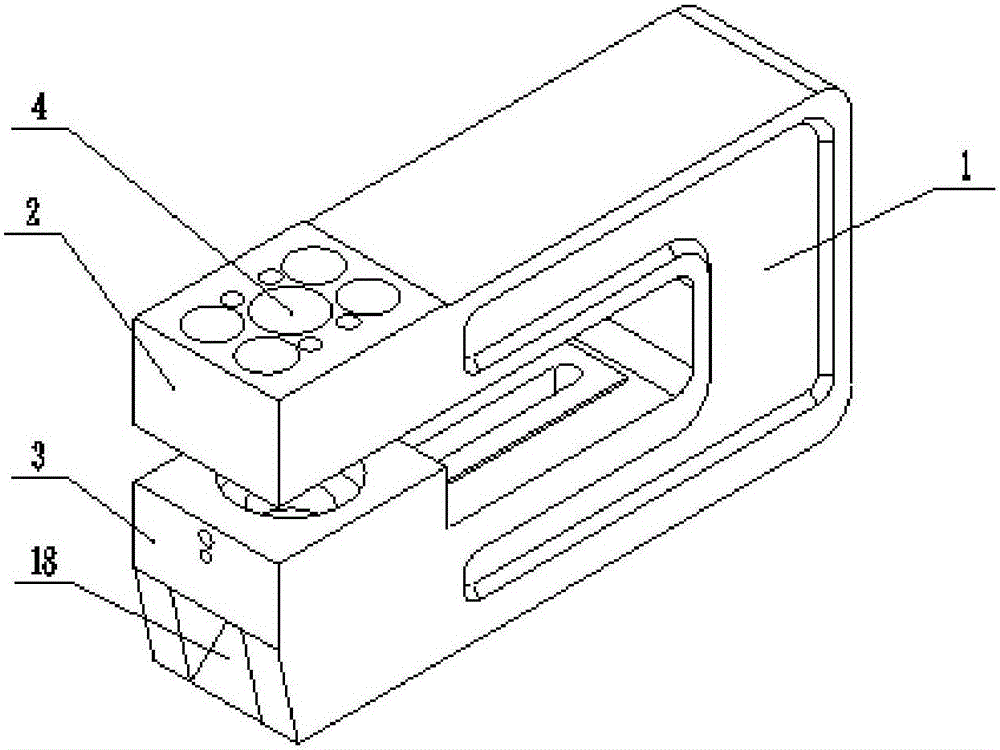

[0038] Such as figure 1 with figure 2 As shown, a sheet metal punching die of this embodiment includes a die base 1, a punch 7, a die 15, a contour screw 10, and a die fixing plate 14. Wherein, the mold base 1 has a "C"-shaped structure, and the two ends of the opening respectively have a punch support portion 2 and a die support portion 3; the punch support portion 2 is provided with a punch accommodating hole 4 , The punch 7 is arranged in the punch accommodating hole 4, the upper end of the punch 7 is threadedly connected with a hitting head 9; the punch 7 between the hitting head 9 and the punch support 2 is sleeved with a support plate 6 The discharging spring 8 is provided between the pallet 6 and the striking head 9, and the bracket spring 5 is provided between the pallet 6 and the punch support part 2. The elastic coefficient of the discharging spring 8 is greater than that of the bracket spring 5. coefficient. One end of the equal-height screw 10 is connected with t...

Embodiment 2

[0052] The basic structure of a plate punching die of this embodiment is the same as that of embodiment 1, except that the distance from the lower end surface of the punch 7 to the upper surface of the die 15 is A, then Among them: b is the value of sheet thickness in millimeters, the value range of b is 2-20mm, β and λ are constant coefficients, β=4.8-5.2, λ=37-41; specifically in this embodiment, Punching the plate with thickness b=10mm, and take β=5, λ=39, then A=15.7mm.

[0053] Use the above-mentioned plate punching die to punch a plate with a thickness of b=10mm and punch out a circular hole with a diameter of 20mm. The operation steps are as follows:

[0054] 1) Install the die set 1 on the worktable of the punch press, and select the corresponding punch 7 and die 15 according to the hole with a diameter of 20mm to be punched;

[0055] 2) Install the die 15 on the die support 3 through the die fixing plate 14; install the punch 7 into the punch accommodating hole 4 of the pun...

Embodiment 3

[0062] The basic structure of a plate punching die of this embodiment is the same as that of embodiment 1, except that the distance from the lower end surface of the punch 7 to the upper surface of the die 15 is A, then Among them: b is the value of sheet thickness in millimeters, the value range of b is 2-20mm, β and λ are constant coefficients, β=4.8-5.2, λ=37-41; specifically in this embodiment, Punching the plate with thickness b=20mm, and taking β=5.2, λ=37, then A=26.4mm.

[0063] Use the above-mentioned plate punching die to punch a plate with a thickness of b=20mm and punch out a circular hole with a diameter of 20mm. The operation steps are as follows:

[0064] 1) Install the die set 1 on the worktable of the punch press, and select the corresponding punch 7 and die 15 according to the hole with a diameter of 20mm to be punched;

[0065] 2) Install the die 15 on the die support 3 through the die fixing plate 14; install the punch 7 into the punch accommodating hole 4 of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com