Full-automatic punching numerical control machine tool and control method thereof

A CNC machine tool and automatic punching technology, which is applied in the field of CNC machine tools, can solve problems such as wasting time and complicated operations, and achieve the effects of avoiding interference, saving time, and saving human participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

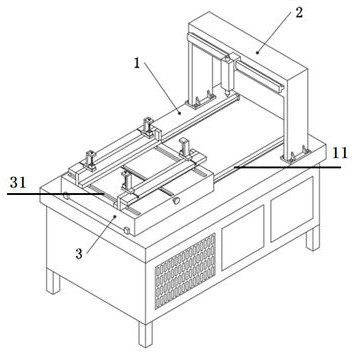

[0047] Combine below Figure 1 to Figure 13 , the present invention is further described:

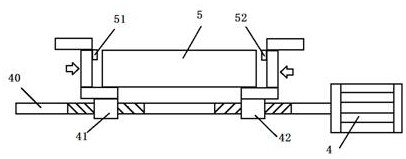

[0048] A fully automatic punching CNC machine tool, comprising a frame 1 and an automatic punching drill bit, a movable positioning table 3 is arranged on the frame 1, and the positioning table 3 fixes the punching workpiece 5 through a clamping and limiting device, It also includes a control unit, the control unit controls the drive mechanism to move the positioning table 3 to the bottom of the automatic punching drill, and the clamping and limiting device sequentially clamps and limits the punching workpiece 5 during the above-mentioned moving process.

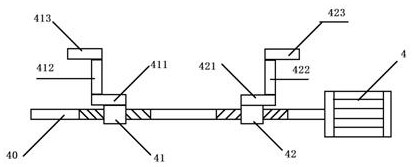

[0049] The drive mechanism includes a first drive motor 4 and a two-way screw 40. The two-way screw 40 is composed of two sections of threaded rods with opposite directions of rotation. The first drive motor 4 drives the two-way screw 40 to rotate, and the two sections of the two-way screw 40 rotate. The opposite threads connect the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com