A micro complex part modeling method based on feature recognition

A complex part and feature recognition technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of large bandwidth of feature points, affecting the accuracy of feature line reconstruction, easy to miss, etc., to reduce the number of personnel involved. , the effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

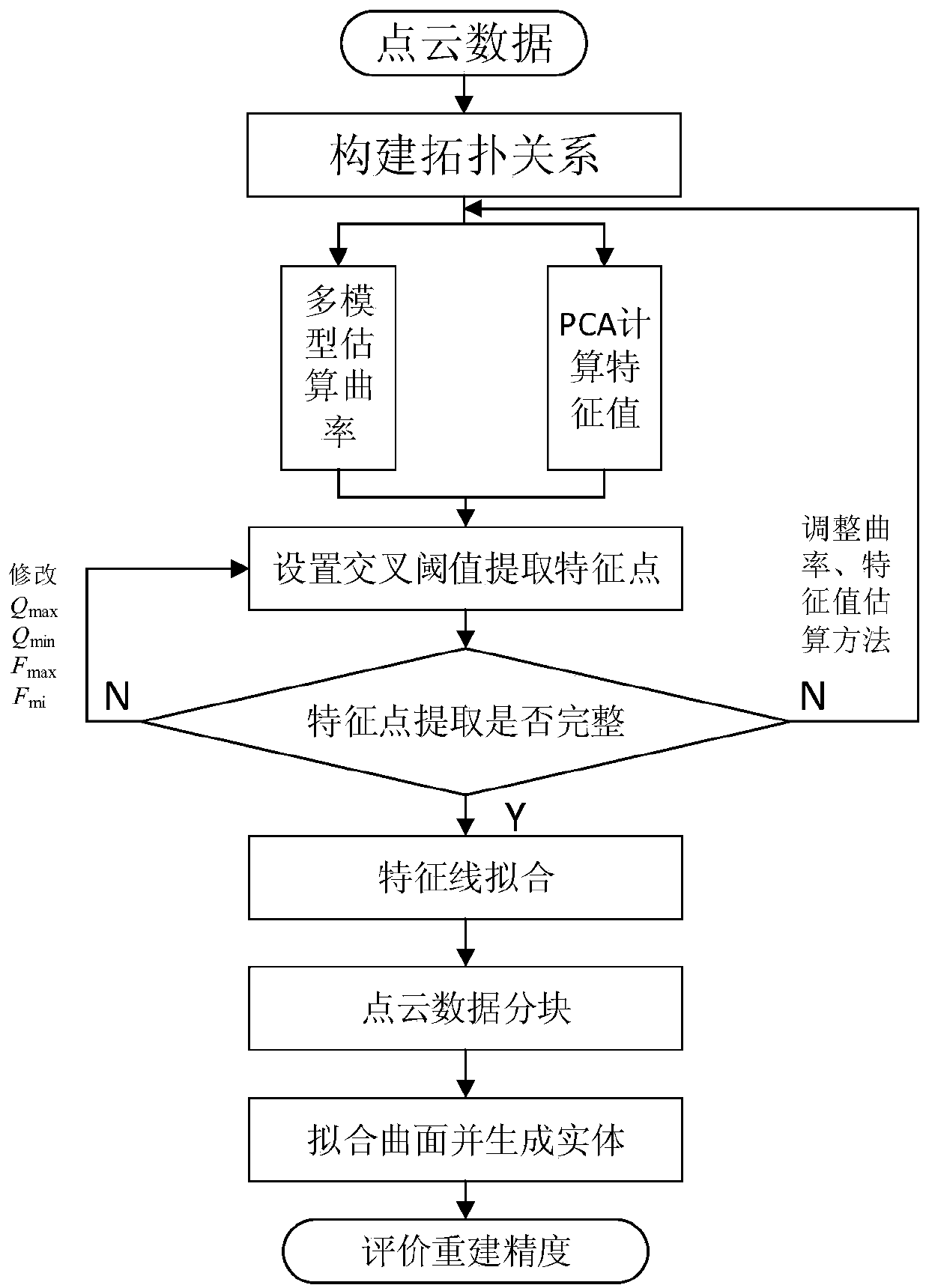

[0052] Such as figure 1 As shown, the feature recognition-based miniature complex part modeling method of the present invention mainly includes four steps: establishment of scattered point cloud topological relationship, feature point extraction, point cloud data block, and model reconstruction. Among them, the step of "establishing the topological relationship of scattered point cloud" is responsible for finding the k nearest neighbor points of each sampling point; the step of "extracting feature points" is responsible for extracting the feature points of the point cloud model; the step of "blocking point cloud data" is responsible for constructing the feature Lines to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com