Anti-deformation tubular product punching and stamping mold

A stamping die and anti-deformation technology, which is applied in the field of stamping dies, can solve problems such as pipe burrs, unfavorable punching processing time, scrapped parts, etc., and achieve the effect of ensuring the quality of punching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

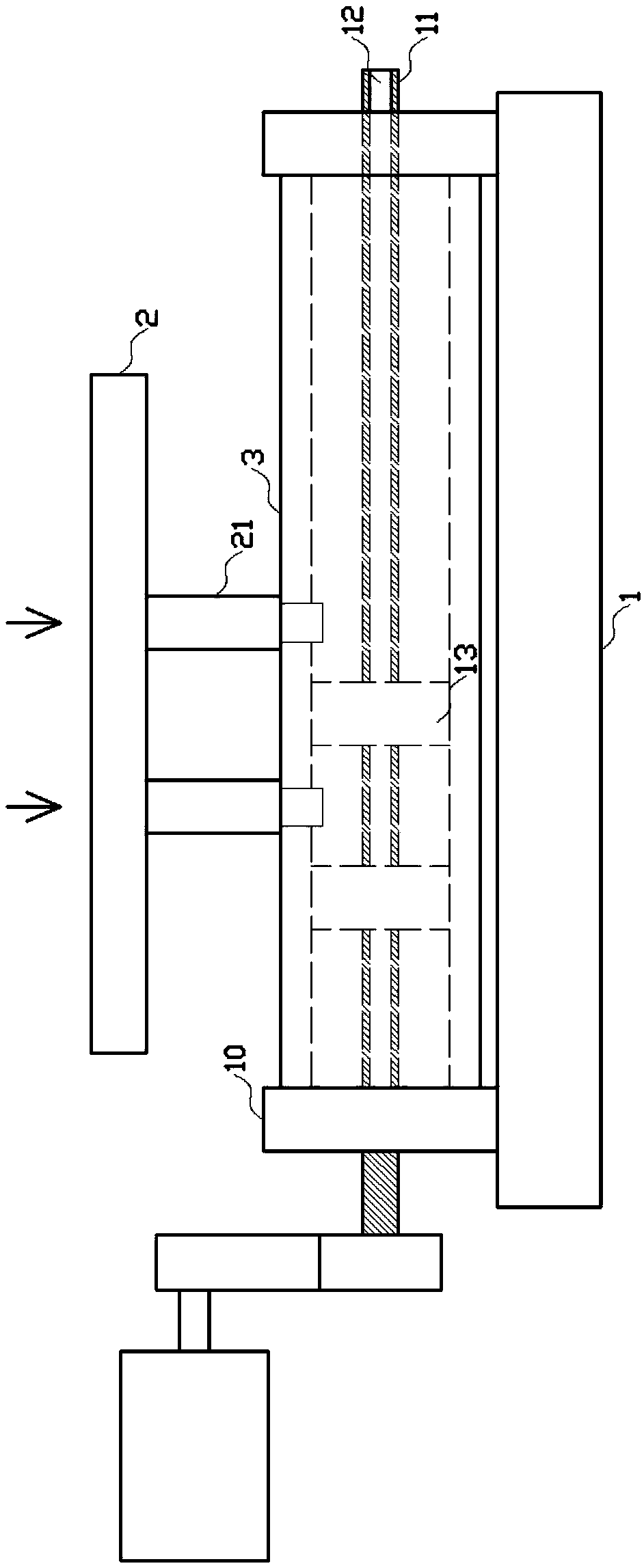

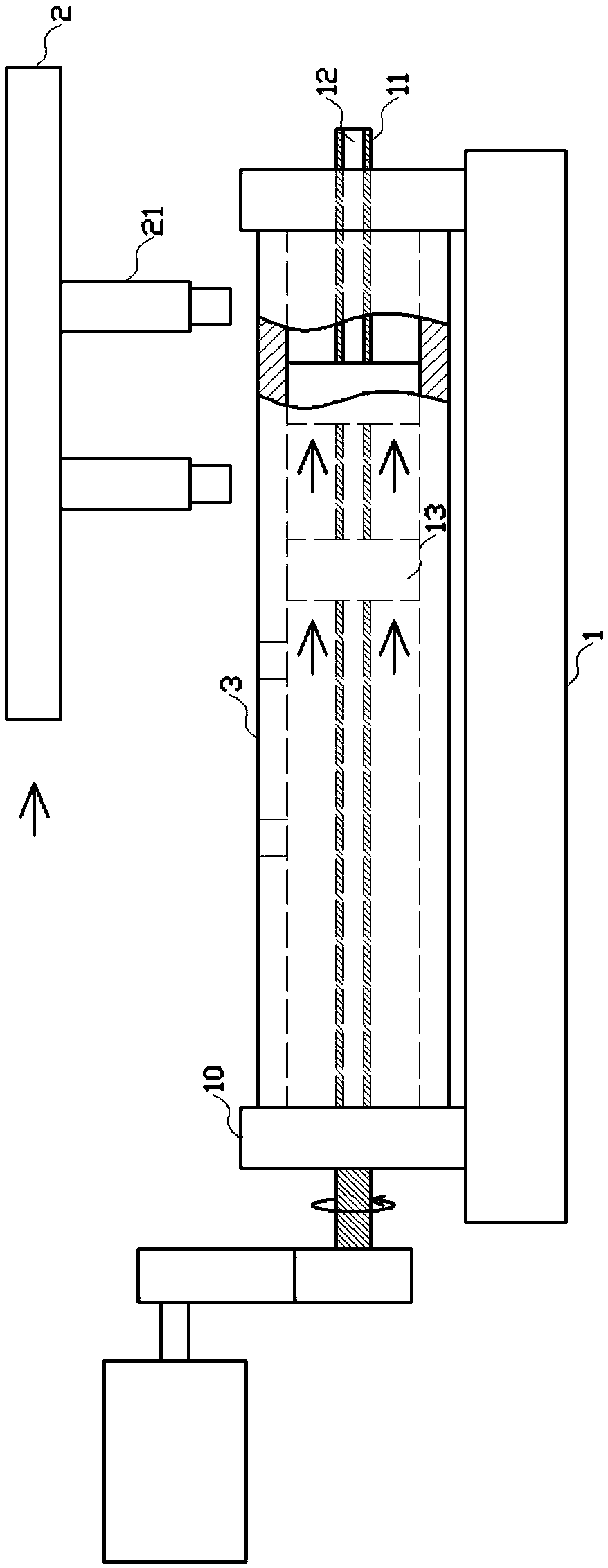

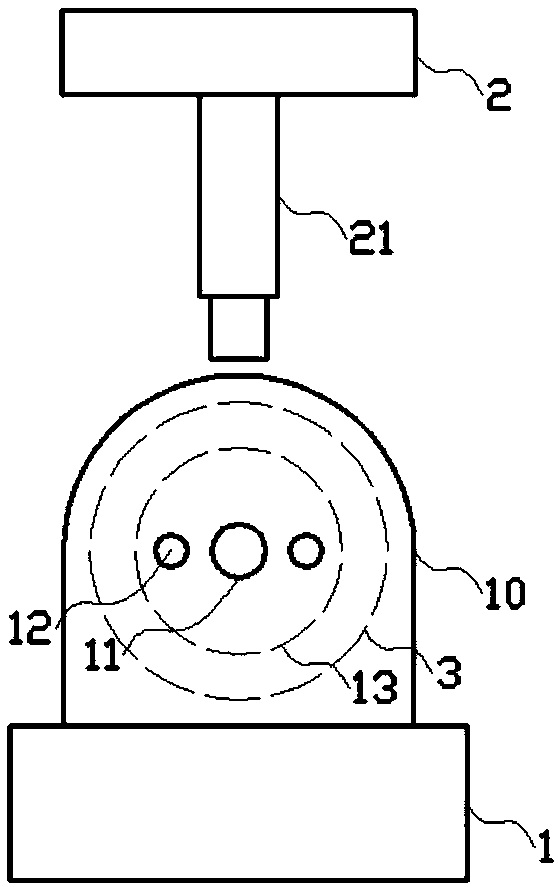

[0016] Such as figure 1 , figure 2 , image 3 As shown in the embodiment, the anti-deformation pipe punching die is a kind of support structure installed inside the pipe, so that the pipe has sufficient support force to prevent its deformation and bending during punching; in addition, the internal thread transmission structure can A device for adjusting the position of the support structure corresponding to the position of the punching hole to realize the supporting effect during porous processing, which includes a positioning adjustment module 1 and a punching module 2; the punching module 2 includes a punching rod 21, and the punching rod 21 A stamping head is provided, and the punching module 2 is installed directly above the positioning adjustment module 1; the positioning adjustment module 1 includes a base, and the base is slidably assembled on a slide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com