Press fitting device for micro fan impeller

A press-fitting device and micro-fan technology, which is applied in wind power generation, metal processing equipment, metal processing, etc., can solve the problems affecting the dynamic balance and noise of the fan, the deviation of the rotor shaft and the impeller hole, and the large runout of the impeller and the shaft. , to achieve the effect of high press-fitting safety, elimination of dynamic balance and noise, and high press-fitting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

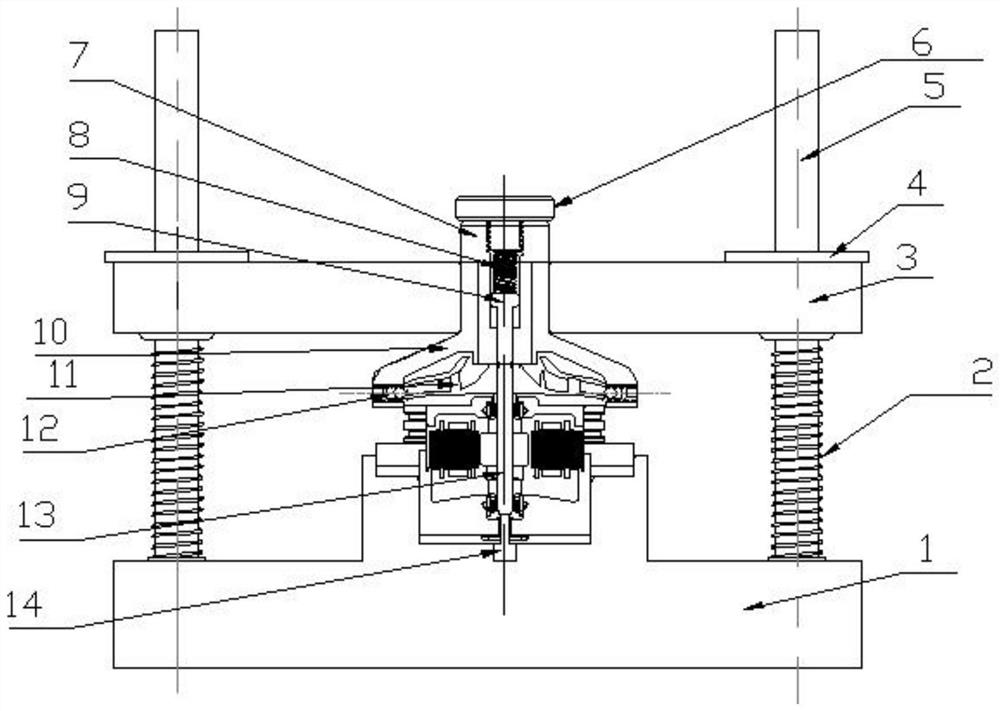

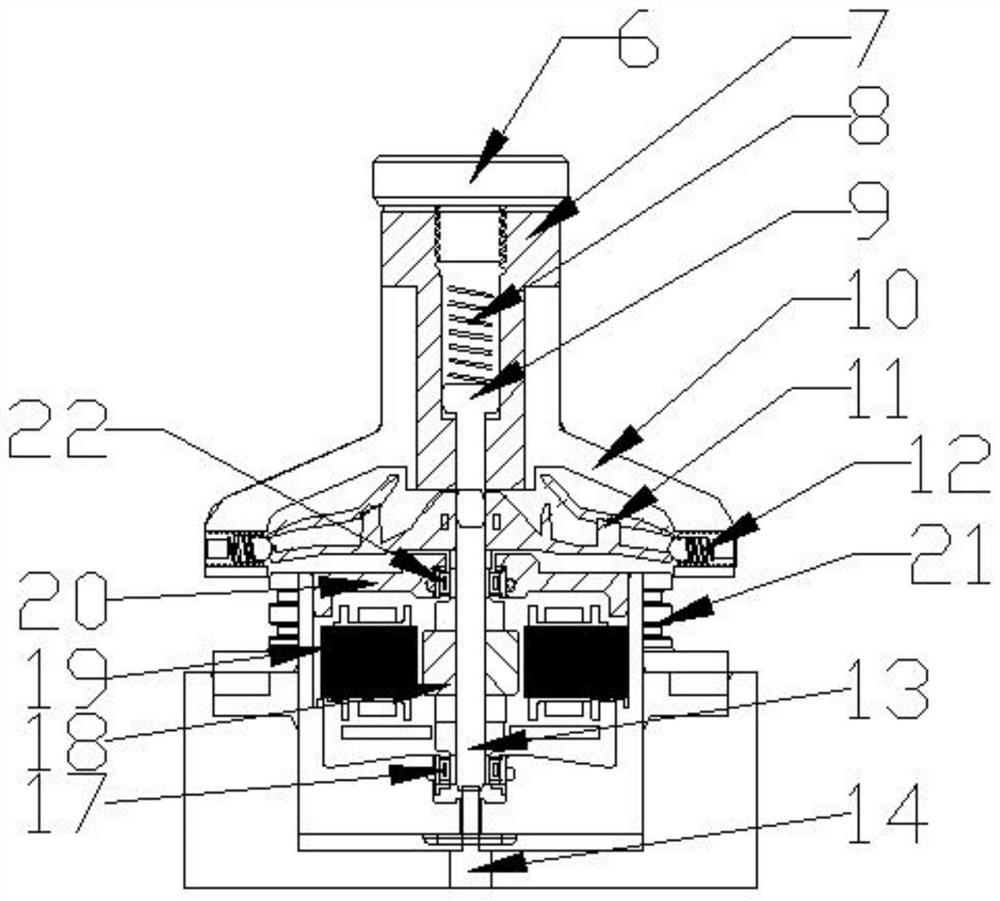

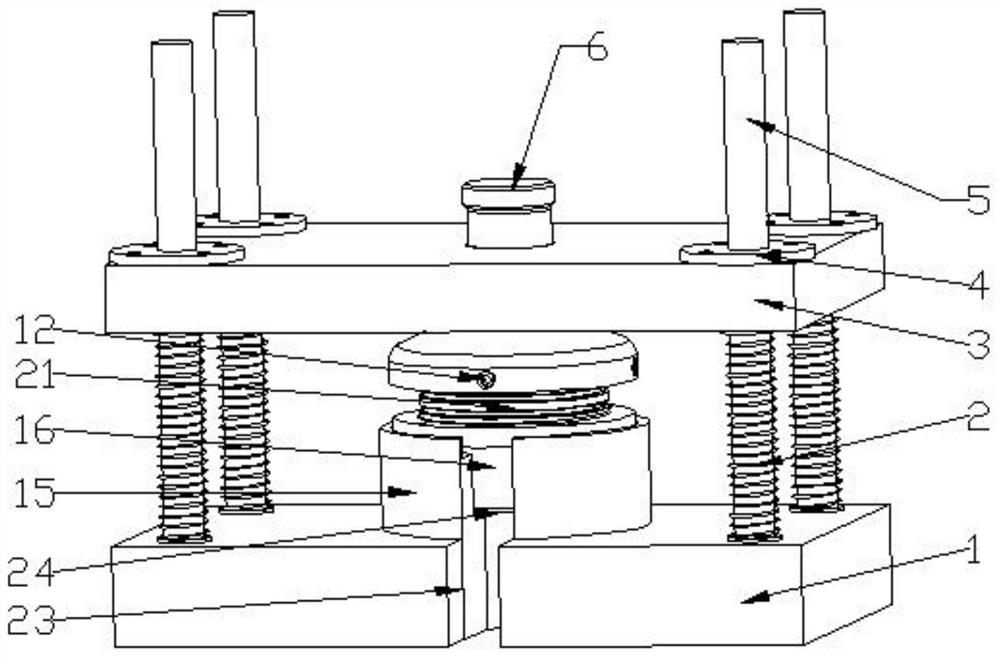

[0019] like Figure 1-4 As shown, a micro-fan impeller press-fitting device includes a positioning base plate 1, a plurality of guide rails 5 are symmetrically installed on the upper end of the positioning base plate 1, and an upper movable positioning plate 3 is slidably connected between the left and right guide rails 5. The positioning plate 3 moves up and down under the limiting action of the guide rail 5. The guide rail 5 between the upper movable positioning plate 3 and the positioning bottom plate 1 is sleeved with a spring 2, and the spring 2 can release the upper movable positioning plate 3 from being pressed. state, make it return to its original position, and prepare for the next press-fitting. An impeller fixing plate 10 is installed in the center of the movable positioning plate 3. The impeller fixing plate 10 elastically fixes the impeller 11 through a plurality of spring plungers 12. A movable guide pin sleeve 7 is installed in the shaft hole of the impeller 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com