Novel automobile engine transmission mechanism

A technology of automobile engine and transmission mechanism, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as knocking on cylinders, left and right knocking on cylinders, etc., to eliminate unbalanced movement and force, increase engine power, and eliminate knocking The effect of the cylinder phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

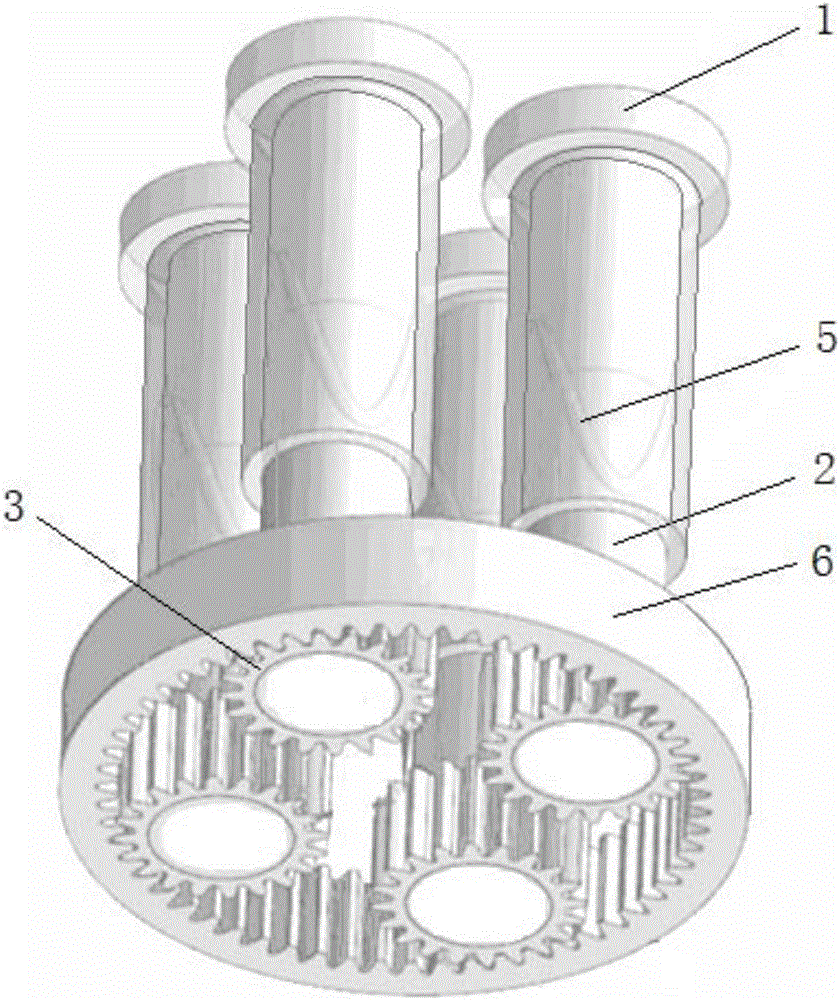

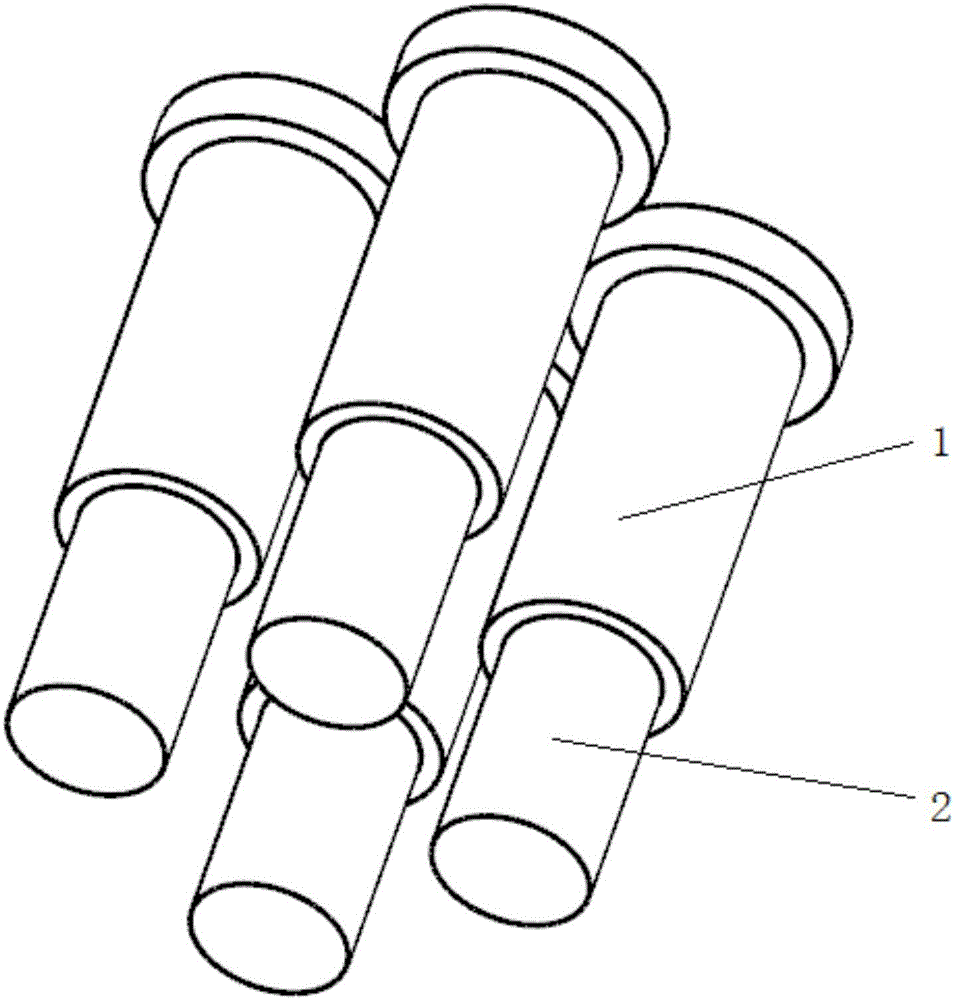

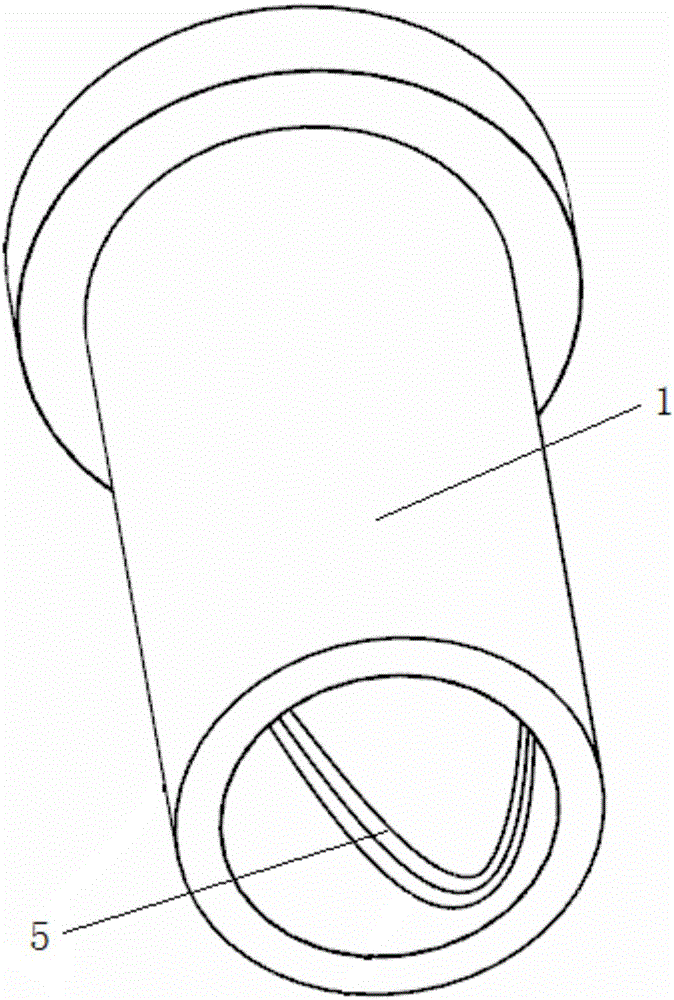

[0023] The invention discloses a novel automobile engine transmission mechanism, such as figure 1 , 2 , 3 and 4, including cylinder, piston 1, connecting shaft 2 and gear 3, the upper part of the piston is slidingly fitted with the cylinder, the piston is a cup-shaped structure with an open lower end, and the connecting shaft is from bottom to top Inserted into the inner hole of the piston, the outer cylindrical surface of the connecting shaft is provided with a hemispherical protrusion 4 or a groove (similar to the groove 5 described later), and the inner cylindrical surface of the piston inner hole is provided with There is a groove 5 or a hemispherical protrusion (similar to the aforementioned protrusion 4), the hemispherical protrusion on the connecting shaft is preferably located on the upper part of the connecting shaft, and the piston and the connecting shaft pass through the hemispherical protrusion Cooperate with the groove to realize movable connection, and the groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com