Method of improving tensile property of aluminum alloy

A technology for tensile properties and aluminum alloys, which is applied in the field of aluminum alloys, can solve the problems of general tensile properties of cast aluminum alloys and poor tensile properties of aluminum alloys, achieve the elimination of coarse non-equilibrium solidification eutectic and dendrite segregation, and improve tensile properties. elongation, grain refinement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

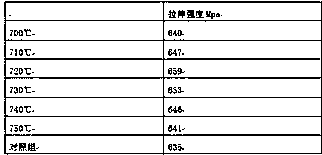

Examples

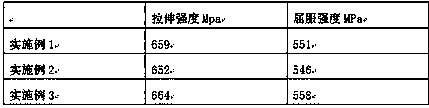

Embodiment 1

[0020] A method for improving the tensile properties of aluminum alloys, which includes ultrasonic treatment of aluminum alloy solutions and high-temperature and high-pressure treatment of formed aluminum alloy castings;

[0021] The percentage mass of strontium in the aluminum alloy is: 0.022%;

[0022] The percentage mass of cerium in the aluminum alloy is: 0.011%;

[0023] The mass percentage of zirconium in the aluminum alloy is: 0.22%.

[0024] As a further technical solution, the percentages of other elements in the aluminum alloy are: Si0.32%, Mn0.14%, Cr0.06%, Mg1.3%, Cu0.18%, Ti0.5%, B0.03 %, Sb0.10%, Fe0.12%, and the rest is aluminum.

[0025] As a further technical solution, the mass ratio of strontium to cerium in the aluminum alloy is 2:1.

[0026] As a further technical solution, the mass ratio of strontium to zirconium in the aluminum alloy is 1:10.

[0027] As a further technical solution, the ultrasonic treatment of the aluminum alloy solution is to perfor...

Embodiment 2

[0033] A method for improving the tensile properties of aluminum alloys, which includes ultrasonic treatment of aluminum alloy solutions and high-temperature and high-pressure treatment of formed aluminum alloy castings;

[0034] The percentage mass of strontium in the aluminum alloy is: 0.026%;

[0035] The percentage mass of cerium in the aluminum alloy is: 0.013%;

[0036] The percentage mass of zirconium in the aluminum alloy is: 0.26%.

[0037] As a further technical solution, the percentages of other elements in the aluminum alloy are: Si0.32%, Mn0.14%, Cr0.06%, Mg1.3%, Cu0.18%, Ti0.5%, B0.03 %, Sb0.10%, Fe0.12%, and the rest is aluminum.

[0038] As a further technical solution, the mass ratio of strontium to cerium in the aluminum alloy is 2:1.

[0039] As a further technical solution, the mass ratio of strontium to zirconium in the aluminum alloy is 1:10.

[0040] As a further technical solution, the ultrasonic treatment of the aluminum alloy solution is to perfor...

Embodiment 3

[0046] A method for improving the tensile properties of aluminum alloys, which includes ultrasonic treatment of aluminum alloy solutions and high-temperature and high-pressure treatment of formed aluminum alloy castings;

[0047] The percentage mass of strontium in the aluminum alloy is: 0.024%;

[0048] The percentage mass of cerium in the aluminum alloy is: 0.012%

[0049] The percentage mass of zirconium in the aluminum alloy is: 0.24%.

[0050] As a further technical solution, the percentages of other elements in the aluminum alloy are: Si0.32%, Mn0.14%, Cr0.06%, Mg1.3%, Cu0.18%, Ti0.5%, B0.03 %, Sb0.10%, Fe0.12%, and the rest is aluminum.

[0051] As a further technical solution, the mass ratio of strontium to cerium in the aluminum alloy is 2:1.

[0052] As a further technical solution, the mass ratio of strontium to zirconium in the aluminum alloy is 1:10.

[0053] As a further technical solution, the ultrasonic treatment of the aluminum alloy solution is to perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com