Novel, full-automatic and efficient punching machine

A fully automatic, punching machine technology, applied in the field of punching machines, can solve problems such as affecting punching efficiency and punching quality, difficult to automatically take out excess materials, and increase labor costs, so as to improve punching quality and facilitate recycling. , the effect of increasing the punching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

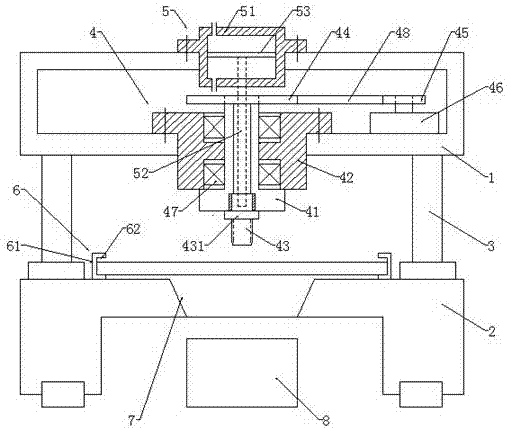

[0014] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0015] As shown in the figure, a new type of fully automatic high-efficiency punching machine is characterized in that it includes a frame 1 and a workbench 2. There are punching device 4 and clearing device 5, and punching device 4 is arranged on the below of clearing device 5; The motor 46 arranged on the frame 1, the rotary sleeve 41 is rotatably supported in the support seat 42 by the bearing 47, and the rotary sleeve 41 is provided with a columnar through hole, and the punching head 43 is a cylindrical structure. The lower part of the cylindrical through hole of the rotary sleeve 41 is threaded, and the lower edge of the bottom is a blade edge. The driven gear 44...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com