Punching device of decoration strip products

A decorative strip and product technology, which is applied in metal processing and other directions, can solve the problems of multiple times of taking and taking off products, troublesome processing of porous punching, and difficulty in guaranteeing processing accuracy, so as to reduce labor intensity, reduce production costs, and improve production. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

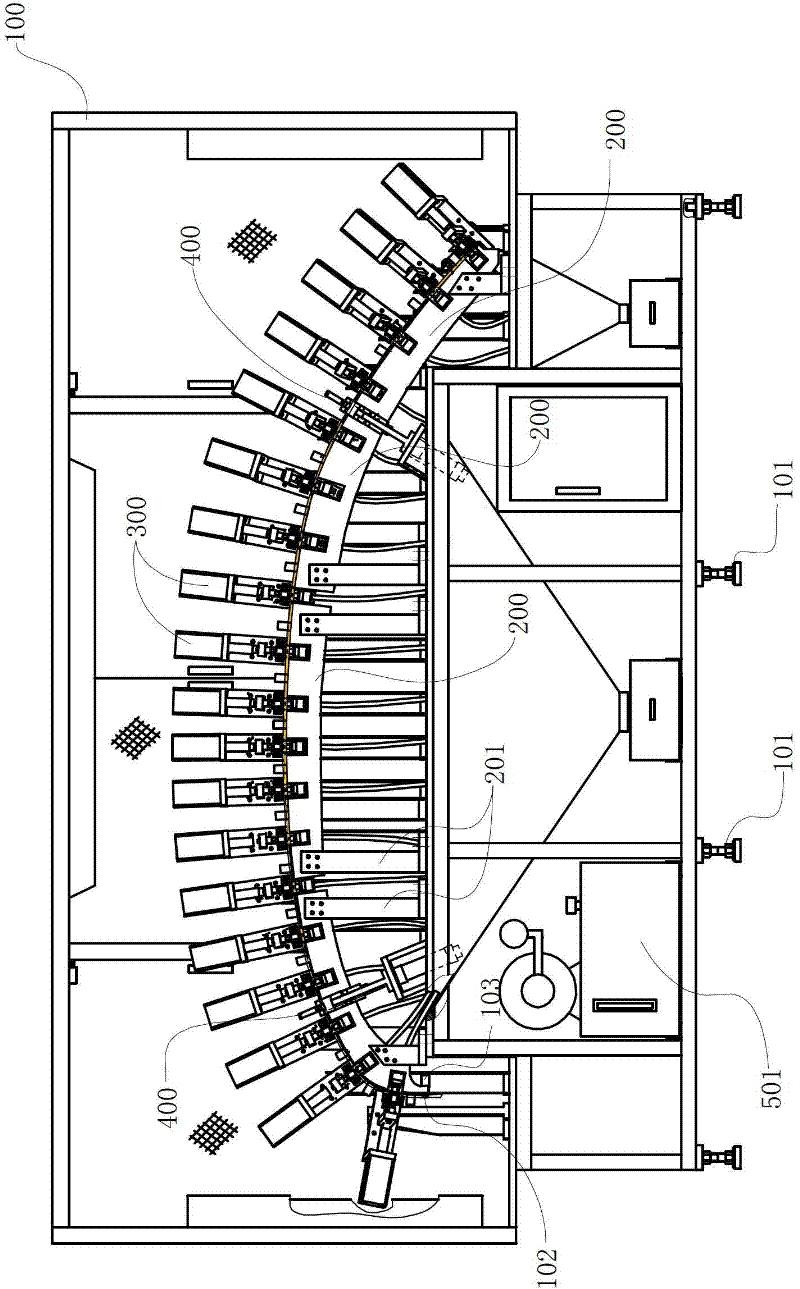

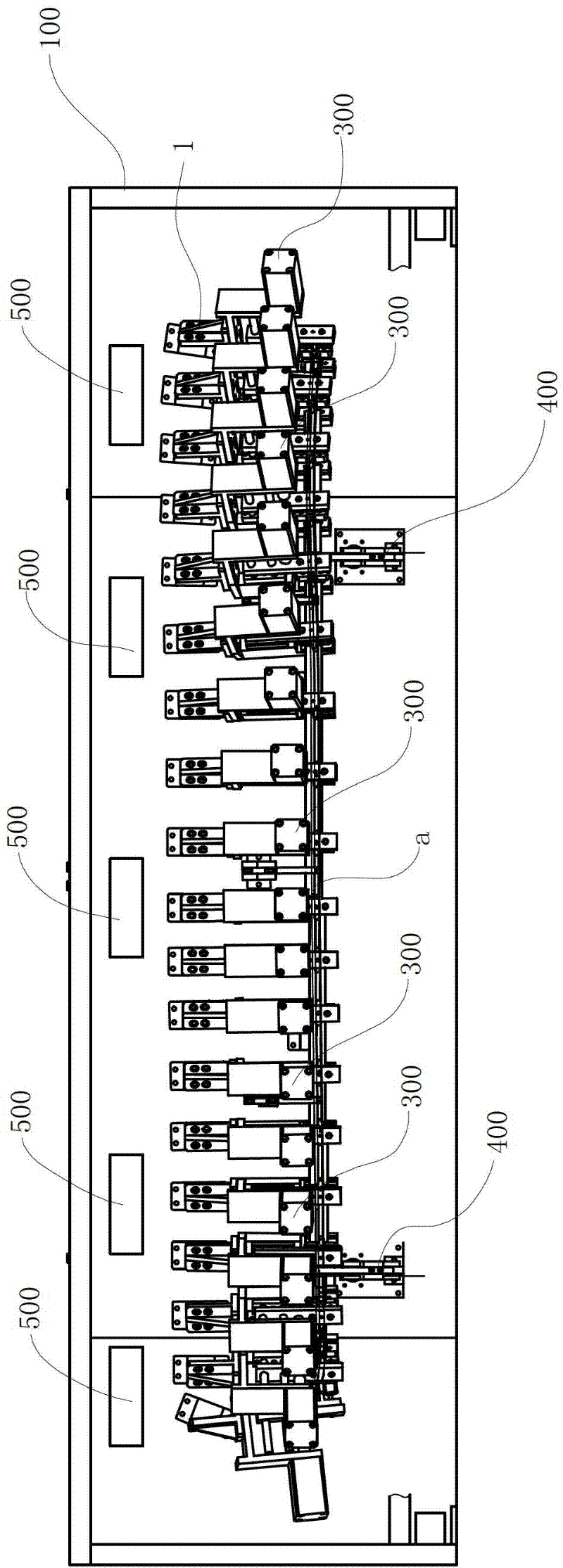

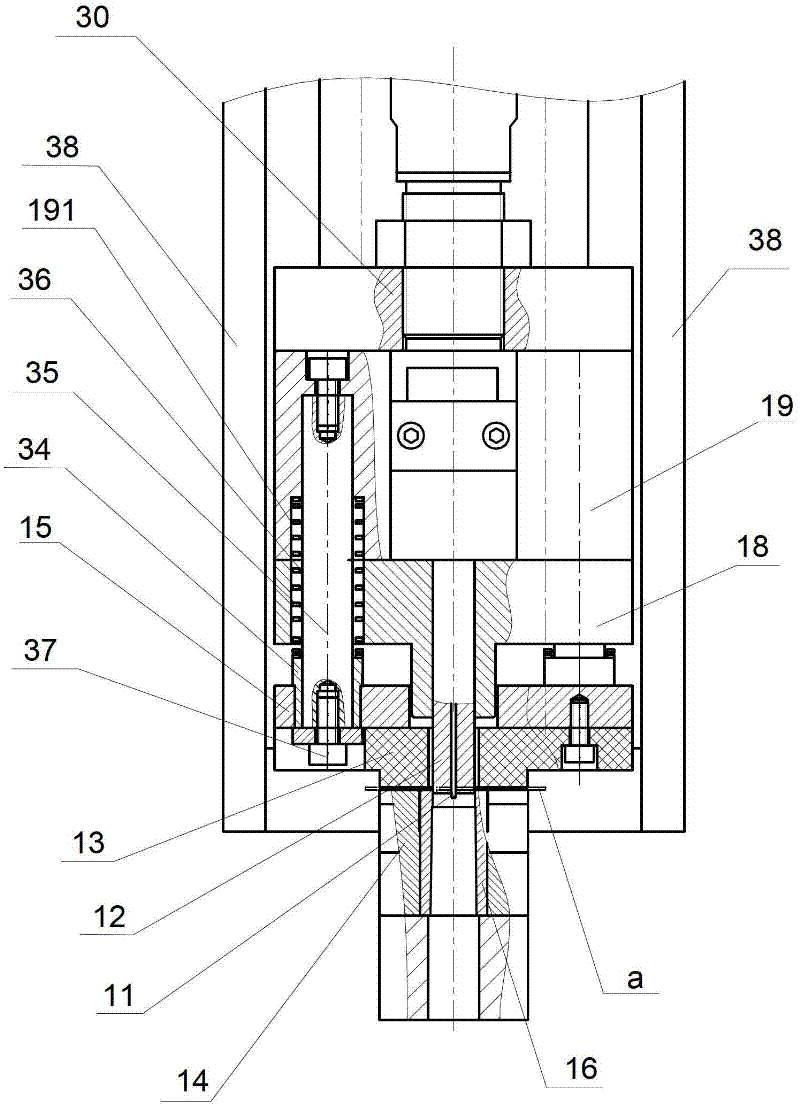

[0026] Punching device of the present invention, as Figure 1-2 As shown, it includes a frame 100, and a plurality of adjustable feet 101 located below the frame 100 can make the frame stable and avoid shaking due to uneven ground. The frame 100 is provided with a plurality of positioning seats separated in turn to form a long positioning seat 200 for placing the workpiece a to be processed when punching. In this embodiment, the spliced positioning seats have a certain radian. To match the workpiece a to be processed, the positioning seat 200 is fixed on the frame 100 through a plurality of vertical positioning seat brackets 201, and on the frame 100 along the length direction of the positioning seat 200, a plurality of The punching assembly 300, and the positioning seat 200 is provided with a plurality of grooves for inserting the die hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com