Honeycomb activated carbon production and processing method

A honeycomb activated carbon and processing method technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve problems such as uneven pore size, affecting the production quality of activated carbon, and affecting the turning effect of stirring plates , to achieve the effect of ensuring the quality of punching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

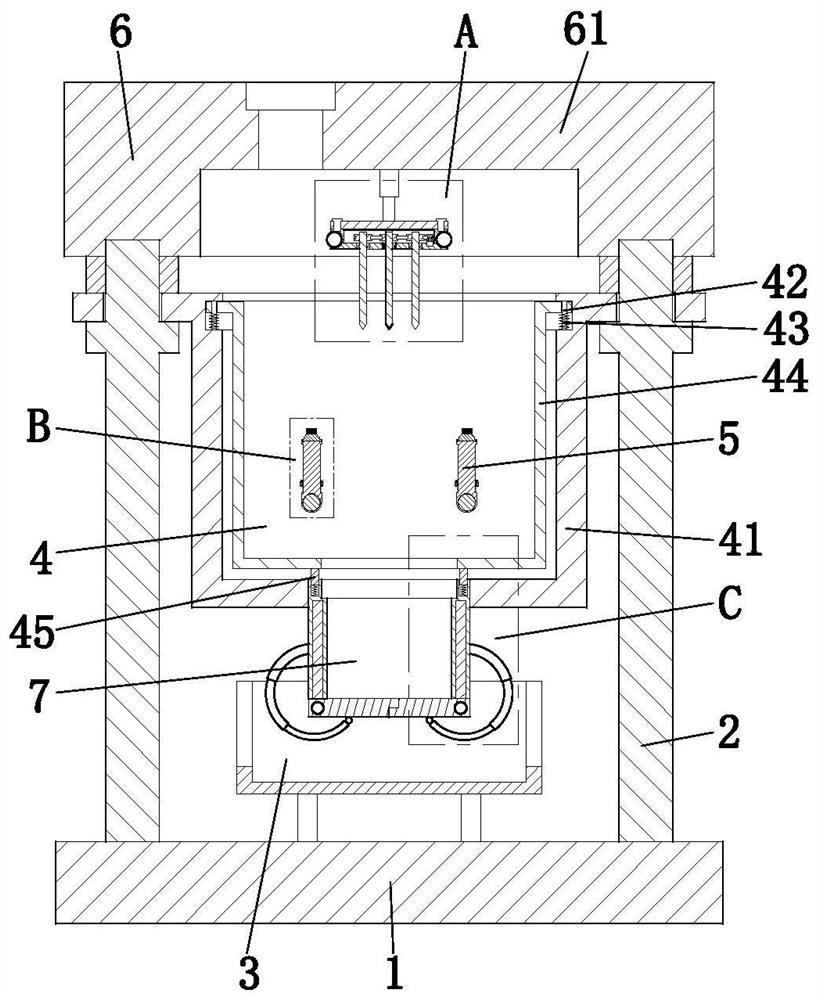

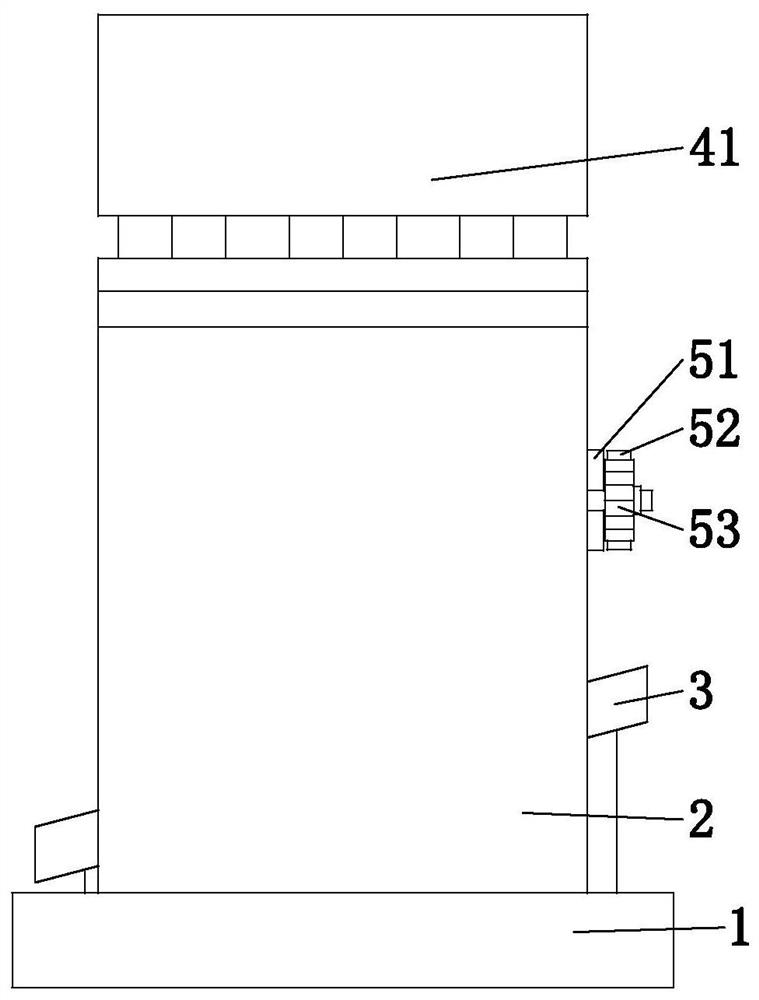

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific drawings. It should be noted that, in the case of no conflict, the embodiments and Features in the embodiments can be combined with each other.

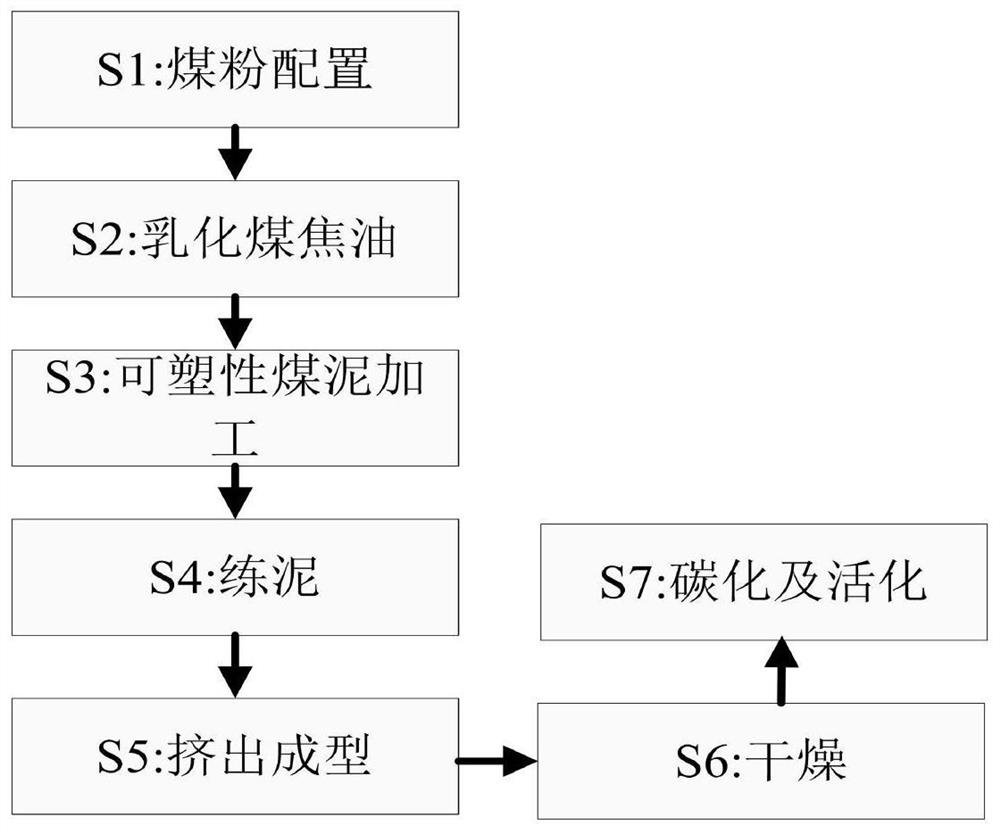

[0032] like Figure 1 to Figure 6 Shown, a kind of honeycomb activated carbon production and processing method, concrete honeycomb activated carbon production and processing method is as follows:

[0033] S1. Coal powder configuration: Brown coal or bituminous coal and coking coal are respectively crushed to ≤2mm, then mixed according to the mass ratio of lignite or bituminous coal:coking coal=1:0.2-0.5, and then ground to below 74 μm to obtain uniformly mixed coal powder;

[0034] S2. Emulsified coal tar: first step, high temperature coal tar with pitch content ≥ 55% is preheated to 120-150°C; second step, preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com