Swarf cleaning device applied to stamping die

A technology for stamping dies and cleaning devices, applied in the directions of cleaning methods and utensils, removing smoke and dust, chemical instruments and methods, etc., can solve the problems of die wear, affecting the blanking quality of workpieces, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

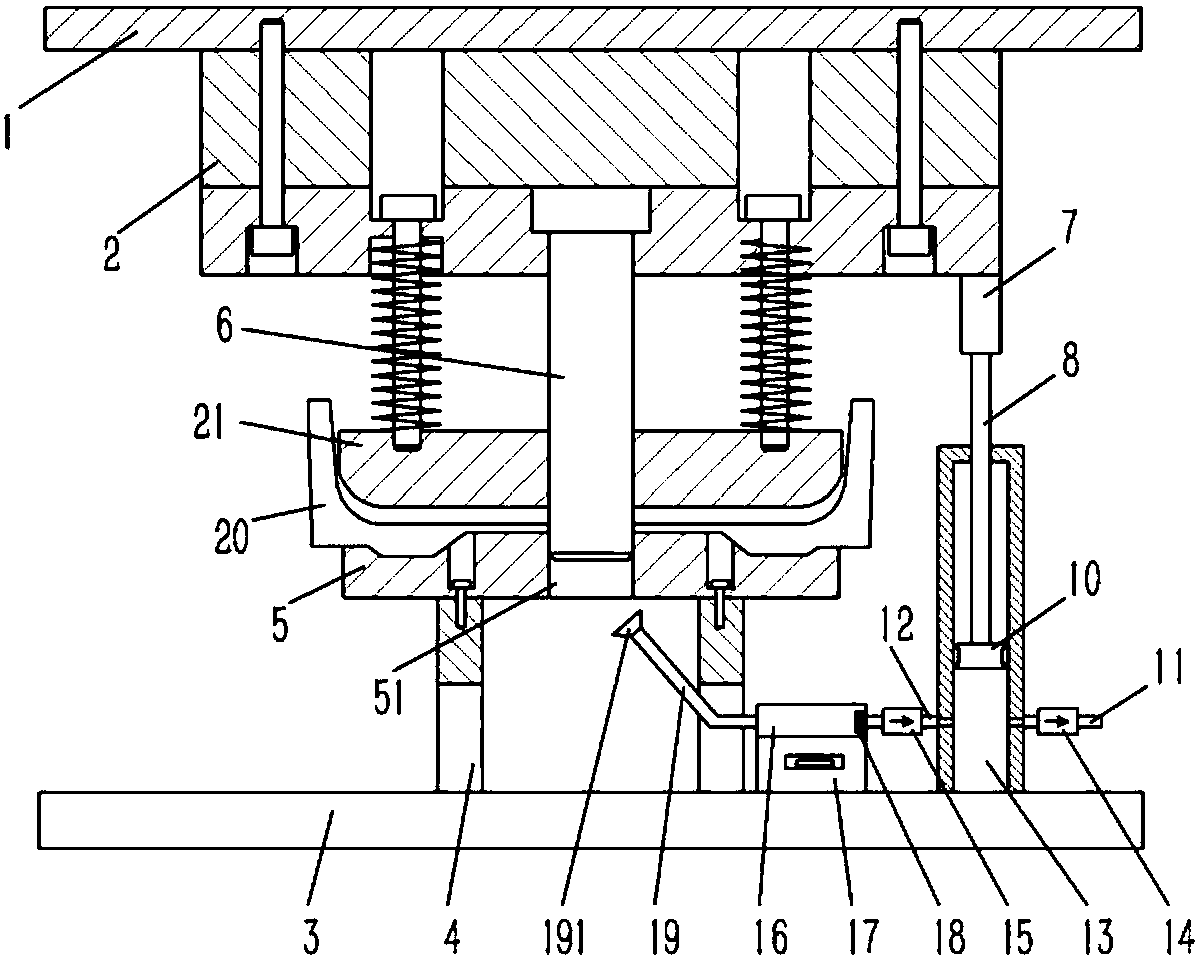

[0014] Example: see figure 1 As shown, a chip cleaning device applied to stamping dies includes an upper die mounting plate 1 and an upper die 2, the upper die 2 is fixed on the lower end surface of the upper die mounting plate 1, and the lower side of the upper die 2 is provided with a lower The mold 5 and the lower mold 5 are fixed on the column 4, the lower end of the column 4 is fixed on the lower mold mounting plate 3, the upper mold 2 is equipped with a lower die 21, and the lower die 21 is inserted with a punch 6, and the punch 6 The upper end of the upper die is fixed on the upper die 2, the lower die 5 is formed with a punching hole 51 opposite to the punch 6, a fixed block 7 is fixed on the side of the upper die 2, and a vertical piston rod 8 is fixed on the fixed block 7. , the lower end of the piston rod 8 is fixed with a piston 10, the piston 10 is inserted in the cylinder 13, the lower end of the cylinder 13 is fixed on the lower mold mounting plate 3, and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com