Building wall punching device and using method thereof

A drilling device and a technology for building walls, which are applied in the field of construction machinery, can solve the problems of manual drilling, drill bit affecting the orientation of drilling, high density, etc., to prevent environmental pollution, avoid drill bit deviation, and ensure drilling quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

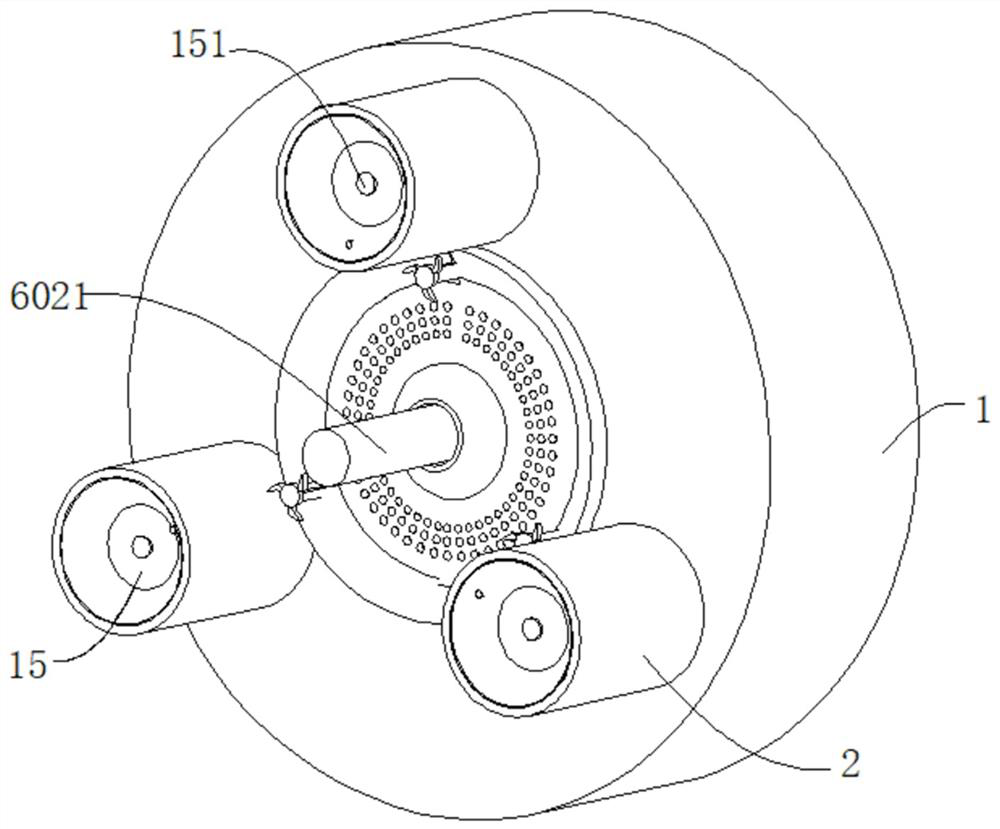

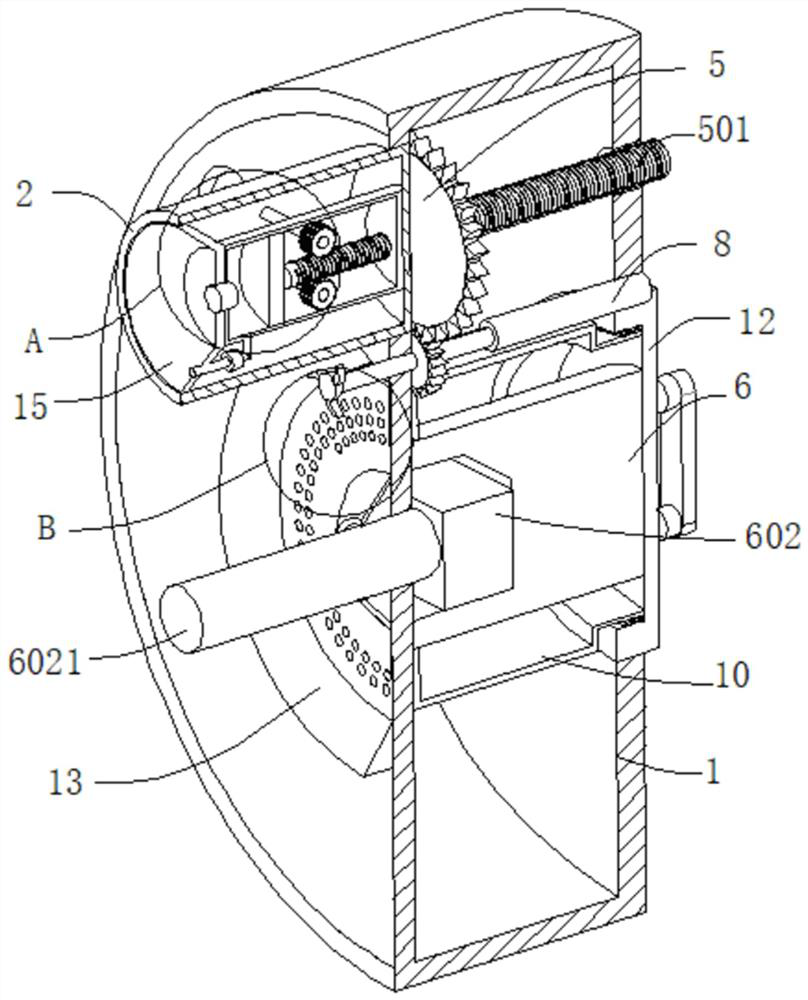

[0037] refer to Figure 1-8 , a building wall punching device, comprising a machine base 1, the outer wall of the machine base 1 is movably connected with three fixed pipes 2, the inner wall of each fixed pipe 2 is fixedly connected with a casing 3, and the inner wall of the casing 3 is connected with a fixing mechanism, The outer wall of the support 1 is connected with a second motor 17, and the output end of the second motor 17 is connected with a rotating rod 8, and the outer wall of the rotating rod 8 is connected with a second gear 7, and the second gear 7 is connected to the inner wall of the support 1 in rotation. The outer wall of the gear 7 is meshed with the first gear 5, the first gear 5 is connected to the outer wall of the fixed pipe 2 in rotation, the outer wall of the first gear 5 is connected with a threaded rod 501, and the outer wall of the machine base 1 is dug with a threaded hole matching the threaded rod 501 4. The inner wall of the machine base 1 is connec...

Embodiment 2

[0040] refer to image 3 , Figure 4 with Image 6 , a building wall punching device, which is basically the same as Embodiment 1, furthermore, the fixing mechanism includes a suction cup 15, the suction cup 15 is fixedly connected to the outer wall of the sleeve 3, the suction cup 15 is placed inside the fixed pipe 2, and the sleeve A first one-way valve 151 is connected between the pipe 3 and the suction cup 15, an exhaust pipe 16 is connected to the outer wall of the sleeve pipe 3, and the end of the exhaust pipe 16 away from the sleeve pipe 3 extends into the suction cup 15, and the outer wall of the exhaust pipe 16 is connected to a The second one-way valve 161, the inner wall of the casing 3 is slidingly connected with a piston 301, the outer wall of the piston 301 is connected with a worm 3011, the outer wall of the worm 3011 is meshed with a first worm wheel 3012, the outer wall of the first worm wheel 3012 is connected with a rotating shaft 3013, and the rotating sha...

Embodiment 3

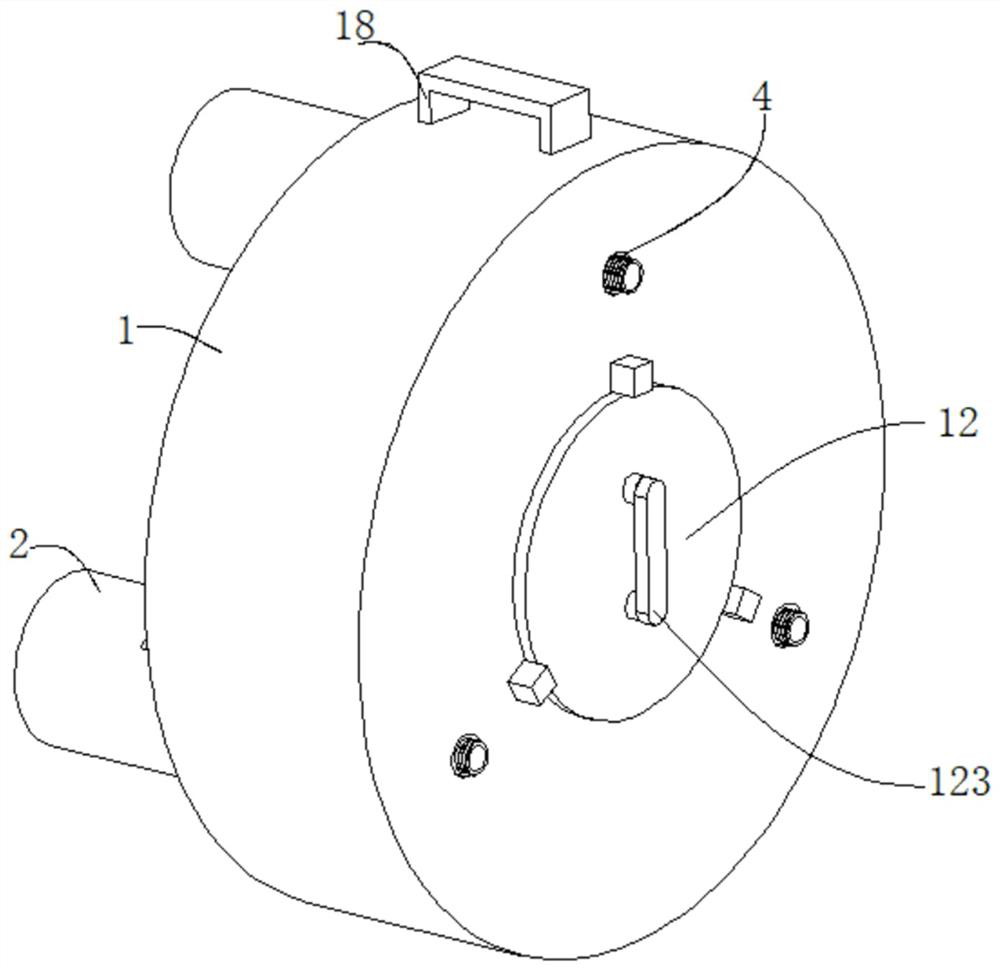

[0043] Referring to 1-8, a building wall punching device is basically the same as Embodiment 1, furthermore, a cover 12 is detachably connected to the base 1, and a handle 123 is connected to the outer wall of the cover 12, and the cover 12 The inner wall is fixed with an internal thread 121, and the outer wall of the annular plate 10 is fixed with an external thread 122 matching the internal thread 121; the machine base 1 is threadedly connected with a cover body 12, which is convenient for discharging the collected dust and avoiding excessive dust in the dust collection chamber. Too much will affect the collection effect of dust.

[0044] Both sides of the outer wall of the machine base 1 are connected with grips 18; by arranging the handles 18 on both sides of the machine base 1, the workers can hold and further reduce the vibration generated during drilling.

[0045] The invention also discloses a method for using a building wall punching device, which includes the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com