Punching device for fuselage frame

A punching device, aircraft fuselage technology, applied in feeding devices, aircraft parts, transportation and packaging, etc., can solve problems such as quality cannot be guaranteed, and achieve the effect of improving punching efficiency, stable high-quality connection, and manufacturing precision control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

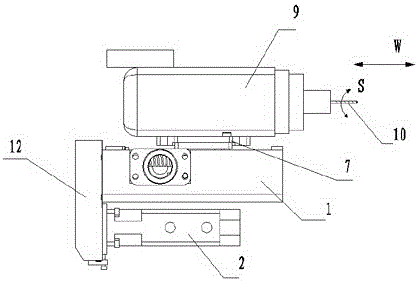

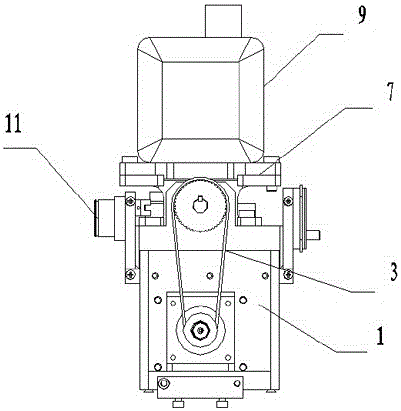

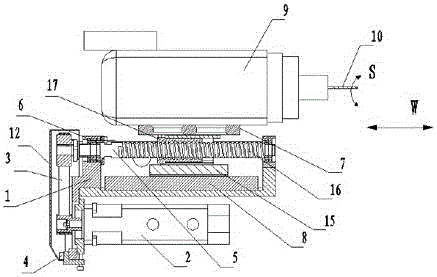

[0020] This embodiment provides an aircraft fuselage frame punching device, and the function of the punching device is to replace manual punching of the aircraft fuselage frame. The device needs to be installed on a three-coordinate machine tool, such as Figure 6 As shown, the three coordinates of the three-coordinate machine tool are three coordinates of x, y, and z. This embodiment is connected to the AC double swing head of the three-coordinate machine tool. AC refers to the two directions of the swing of the double swing head. A direction and C direction, in this embodiment, when punching holes, it performs linear feeding along the W direction in the figure to complete the punching action. Such as Figure 1-Figure 4 As shown, the specific structure of this embodiment is as follows: including a drill bit 10, an electric spindle 9, a mounting plate assembly 1, a connecting seat 7, a support assembly and a drive assembly, the support assembly includes a support guide rail 8...

Embodiment 2

[0023] This embodiment provides an aircraft fuselage frame punching device, and the function of the punching device is to replace manual punching of the aircraft fuselage frame. The device needs to be installed on a three-coordinate machine tool, such as Figure 6 As shown, the three coordinates of the three-coordinate machine tool are three coordinates of x, y, and z. This embodiment is connected to the AC double swing head of the three-coordinate machine tool. AC refers to the two directions of the swing of the double swing head. A direction and C direction, in this embodiment, when punching holes, it performs linear feeding along the W direction in the figure to complete the punching action. Such as Figure 1-Figure 4As shown, the specific structure of this embodiment is as follows: including a drill bit 10, an electric spindle 9, a mounting plate assembly 1, a connecting seat 7, a support assembly and a drive assembly, the support assembly includes a support guide rail 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com