Multi-station automatic blanking machine mechanical device and blanking method

A technology of automatic punching machine and mechanical device, applied in the direction of metal processing, etc., can solve the problem that sealing strip punching equipment cannot complete multi-station punching and precision cutting tasks at the same time, cannot complete different sealing strip punching tasks, punching The position cannot be adjusted flexibly, etc., to achieve the effect of low cost, reliable and accurate positioning, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

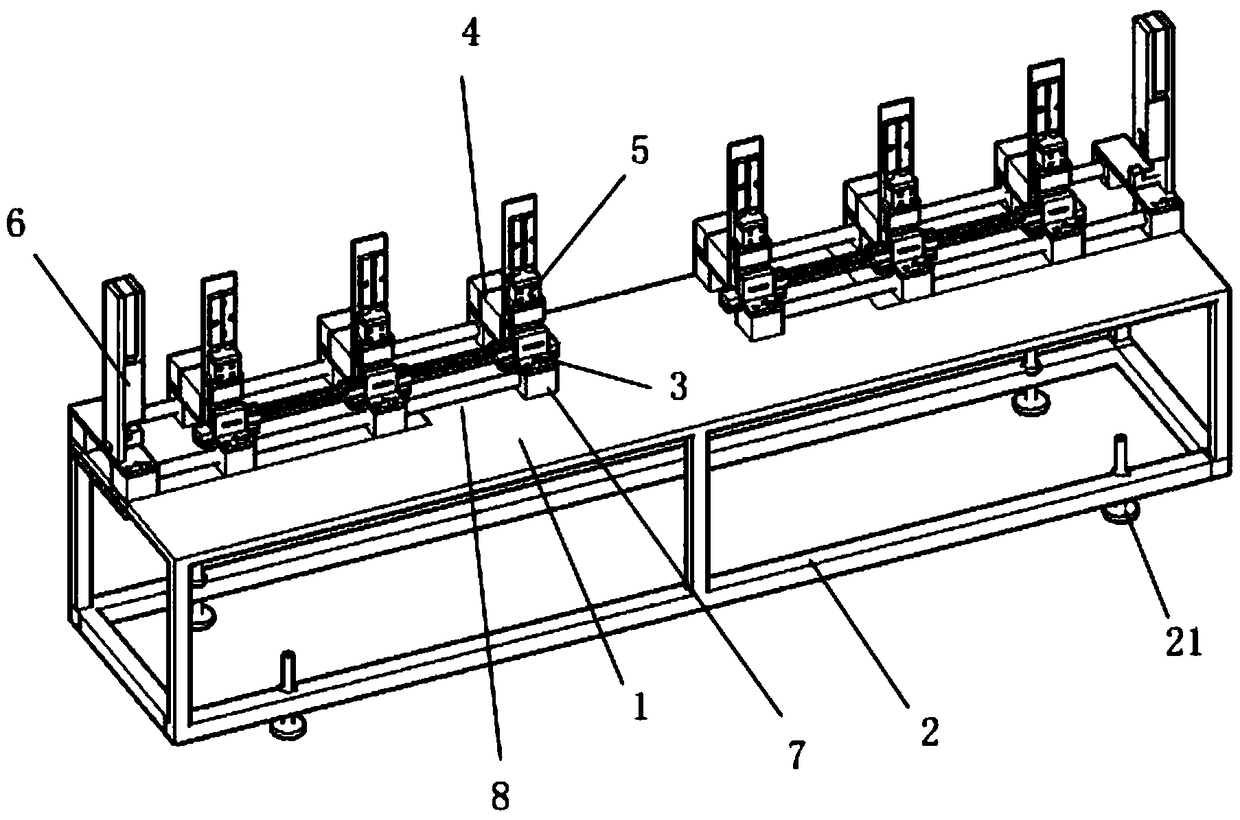

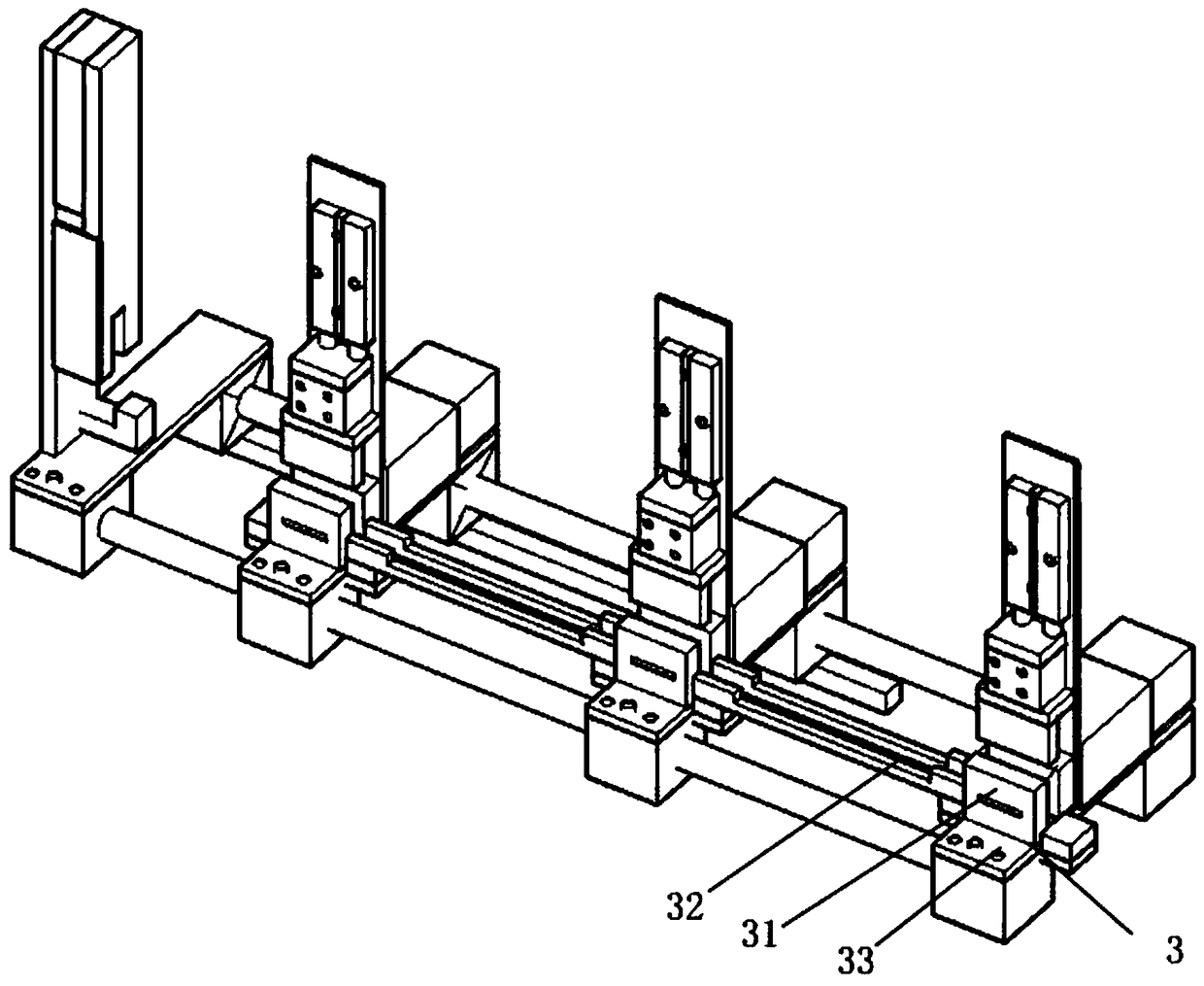

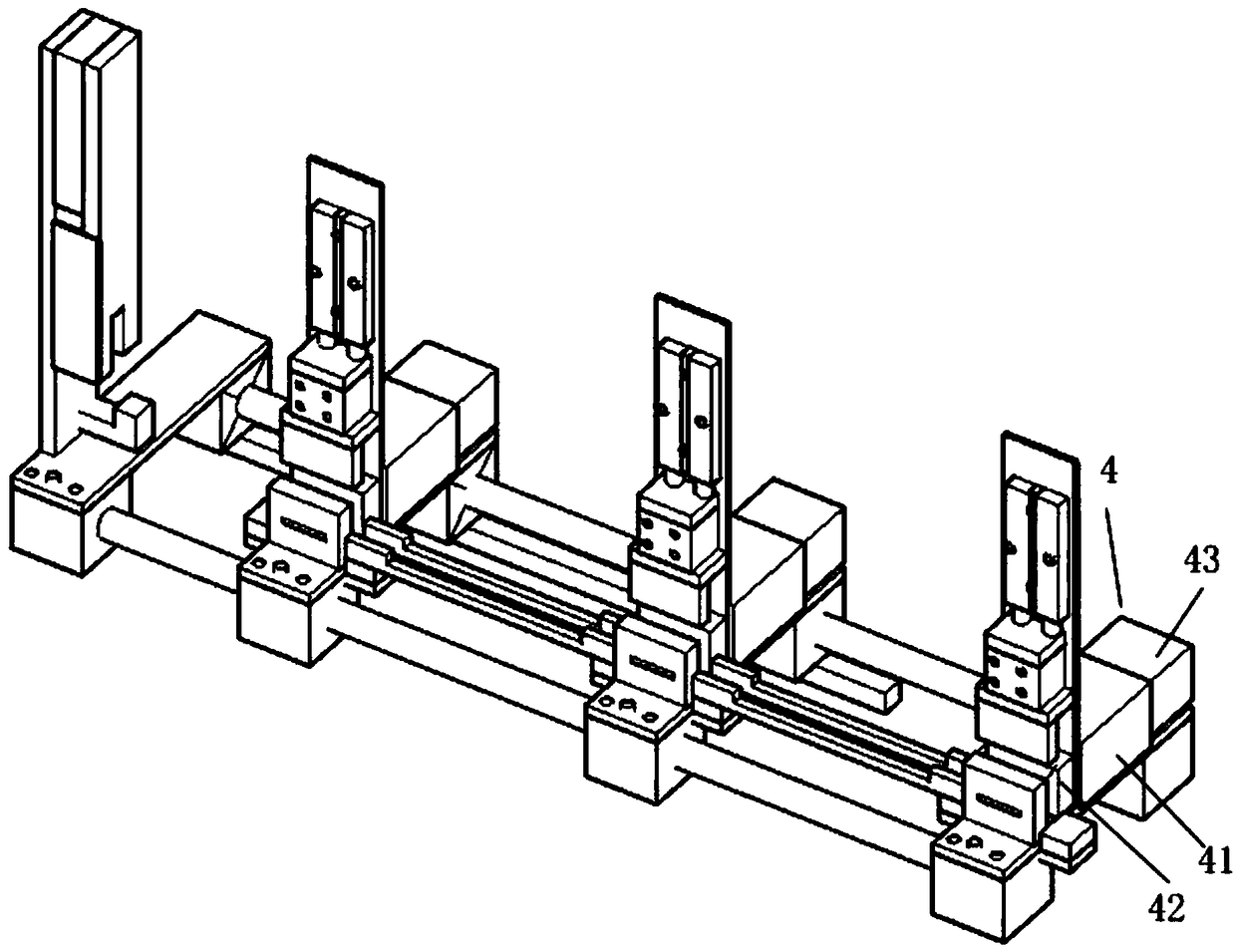

[0035] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0036] The reference signs and components involved in the accompanying drawings are as follows:

[0037] 1. Operating platform 2. Rack

[0038] 21. Ground feet 3. Positioning equipment

[0039] 31. Copy tooling 32. Installation tooling

[0040] 33. Adjustable bottom plate 4. Compression equipment

[0041] 41. Compression cylinder 42. Compression tooling

[0042] 43. Linear guide rail 5. Punching equipment

[0043] 51. Punching cylinder 52. Punching blade

[0044] 6. End cutting equipment 61. Cutting cylinder

[0045] 62. Mounting plate 63. Protective plate

[0046] 64. Cutting blade 7. Sliding seat

[0047] 8. Slider

[0048] Please refer to figure 1 , figure 1 It is a structural schematic diagram of a multi-station automatic punching machine mechanical device of the present invention. A multi-station automatic punchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com