Lifting lug reinforcing board blanking mechanism

A technology of reinforcing plates and punching, applied in the field of stamping dies, can solve the problems of reduced quality of sheet metal parts, increased production costs, and the inability of buffer structures to achieve buffering effects, so as to reduce production costs, reduce material waste, and ensure stable work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

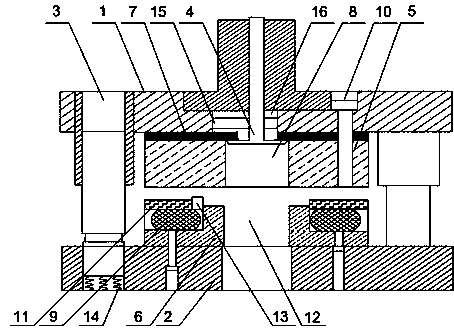

[0021] like figure 1 As shown, a punching mechanism for lifting lug reinforcement plate of the present invention includes an upper die base 1 and a lower die base 2, the upper die base 1 and the lower die base 2 are connected by a positioning column 3, and the upper die base 1 is installed with Stamping die 4, upper mold fixed plate 5 is installed on described upper mold base 1, lower mold fixed plate 6 is installed on described lower mold base 2, set between upper mold fixed plate 5 and upper mold base 1 There is a backing plate 7, the backing plate 7 is connected with the upper die base 1 and the upper die fixing plate 5 through screws 10, the upper die fixing plate 5 has a through hole 8, and the stamping die 4 passes through the upper die base 1 and is placed in the through hole 8 Inside, two rubber blocks 9 are installed on the lower mold fixing plate 6, and an annular flat plate 11 is installed on the rubber blocks 9; a discharge hole 12 is also included, and the dischar...

Embodiment 2

[0023] like figure 1 As shown, on the basis of Embodiment 1, the present embodiment has a rectangular groove 16 on the upper mold base 1, and a guide plate 15 is provided on the wall of the rectangular groove 16, and the stamping die 4 runs through the guide plate 15, and can Move up and down on the guide plate 15. When the stamping die 4 moves down and contacts the material plate, a certain radial vibration will be generated between the two, which will lead to a reduction in the precision of the material plate punching, and finally make the blanked workpiece unqualified, and the workpiece on the rectangular groove 16 wall will be unqualified. The installed guide plate can limit the radial displacement of the stamping die 4 to avoid radial offset of the stamping die 4 and ensure the punching quality of the material plate.

Embodiment 3

[0025] like figure 1 As shown, on the basis of Embodiment 1, the present embodiment has a round hole in the middle of the backing plate 7, the diameter of the round hole is smaller than the diameter of the through hole 8, and the stamping die 4 is placed in the through hole 8 through the round hole. Inside. The backing plate 7 is arranged between the upper die fixing plate 5 and the upper die seat 1, and the stamping die 4 passes through the round hole and is placed in the through hole 8. 7 contact, the circular hole with diameter less than through hole 8 can limit the punching die 4, prevent the punching die 4 from continuing to rise, and avoid the damage of the punching head caused by the collision of the punching die 4 directly with the upper die fixed plate 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com